S.I. No. 640/2007 - Merchant Shipping (Safety of Fishing Vessels) (15-24 Metres) Regulations 2007

ARRANGEMENT OF REGULATIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GENERAL | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. Citation and commencement | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2. Application | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3. Definitions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4. Exemptions and equivalents | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5. Maintenance and upkeep | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6. Repairs, alterations and modifications | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7. Surveys | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8. Surveyor's report and declaration of survey | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

9. Fishing Vessel Safety Certificates and exemption certificates | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10. Duration of Fishing Vessel Safety Certificate | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11. Extension of Fishing Vessel Safety Certificate | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12. Cancellation of certificates and Cesser | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CONSTRUCTION, WATERTIGHT INTEGRITY AND EQUIPMENT | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

13. Construction | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14. Watertight doors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

15. Hull integrity | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16. Weathertight doors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17. Hatchways closed by wood covers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18. Hatchways closed by covers other than wood | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

19. Machinery space openings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20. Other deck openings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

21. Ventilators | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

22. Air pipes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

23. Sounding devices | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24. Sidescuttles and windows | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

25. Inlets and discharges | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

26. Freeing ports | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

27. Anchor and mooring equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

28. Working decks within an enclosed superstructure | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

29. Tanks for fish in refrigerated (RSW) or chilled (CSW) sea water | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

STABILITY AND ASSOCIATED SEAWORTHINESS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30. Stability | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

31. Stability criteria | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

32. Flooding of fish-holds | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

33. Particular fishing methods | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

34. Severe wind and rolling | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

35. Water on deck | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36. Operating conditions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

37. Ice accretion | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

38. Inclining test | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

39. Stability information | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

40. Portable fish-hold divisions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

41. Freeboard | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

42. Maximum permissible operating draught | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 4 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MACHINERY AND ELECTRICAL INSTALLATIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

43. Definitions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

44. General | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MACHINERY INSTALLATIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

45. Propulsion and auxiliary machinery | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

46. Propeller shafts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

47. Gearboxes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

48. Remote control of propulsion machinery | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

49. Communications between wheelhouse and machinery space | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50. Means of going astern | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

51. Propeller and stern gear | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

52. Controllable pitch propellers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

53. Boilers, feed systems and steam piping arrangements | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

54. Air pressure systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

55. Oil fuel, lubricating oil and other flammable oils — general | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

56. Arrangements for oil fuel installations | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

57. Arrangements for lubricating oil, hydraulic oil and other flammable oils | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

58. Bilge systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

59. Bilge alarms | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60. Exhaust systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

61. Steering gear | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

62. Refrigeration systems for the preservation of the catch | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

63. Spare gear | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ELECTRICAL INSTALLATIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

64. General | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

65. Main source of electrical power | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

66. Emergency source of electrical power | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

67. Distribution systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

68. Cables. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

69. Accumulator (storage) batteries and associated charging equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

70. Precautions against shock, fire and other hazards of electrical origin | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

71. Lighting systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

72. Electric motors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

73. Lightning conductors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PERIODICALLY UNATTENDED MACHINERY SPACES | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

74. Fire prevention | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

75. Protection against flooding | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

76. Alarm system | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

77. Special requirements for machinery, boiler and electrical installations | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

78. Safety system | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FIRE PROTECTION, FIRE DETECTION, FIRE EXTINCTION AND FIRE FIGHTING | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

79. Definitions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

80. Fire protection — general | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

81. Structural fire protection on vessels with hulls constructed of steel or other equivalent material | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

82. Structural fire protection on vessels with hulls constructed of combustible materials | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

83. Ventilation systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

84. Space heaters | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

85. Galley area | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

86. Means for stopping machinery | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

87. Oil fuel installations (cooking ranges and heating appliances) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

88. Liquefied petroleum gas installations (cooking ranges and heating appliances) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

89. Storage of flammable liquids, toxic liquids, toxic gases and compressed gases | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90. Means of escape and emergency exits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

91. Automatic fire alarm and fire detection systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

92. Fire pumps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

93. Fire mains | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

94. Fire hydrants, fire hoses & nozzles | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

95. Portable fire extinguishers — general | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

96. Portable fire extinguishers — vessel requirements | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

97. Fire-extinguishing installations in machinery spaces | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

98. Ready availability of fire-extinguishing appliances | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

99. Cleanliness of machinery spaces | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

100. Fire Control Plan | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

101. Equivalence | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 6 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PROTECTION OF THE CREW | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

102. General protective measures | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

103. Deck openings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

104. Bulwarks, rails and guards | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

105. Stairways and ladders. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

106. Accommodation ladders and gangways | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

107. Galleys | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

108. Lighting in working spaces and areas | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

109. Ventilation in working and storage spaces | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

110. Dangerous areas | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

111. Miscellaneous | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 7 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

LIFE-SAVING APPLIANCES AND ARRANGEMENTS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

112. Definitions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

113. Evaluation, testing and approval of life-saving appliances and arrangements | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

114. Number and types of survival craft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

115. Availability and stowage of survival craft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

116. Embarkation into survival craft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

117. Lifejackets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

118. Immersion suits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

119. Lifebuoys | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120. Line throwing appliances | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

121. Distress signals | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

122. Radio life-saving appliances | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

123. Radar transponders | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

124. Retro-reflective materials on life-saving appliances | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

125. Marking of lifeboats, rescue boats and liferafts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

126. Operational readiness, maintenance and inspections | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

127. Miscellaneous | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 8 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

EMERGENCY PROCEDURES, MUSTERS AND DRILLS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

128. General emergency alarm system, muster list and emergency instructions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

129. Abandon ship training and drills | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

130. Training in emergency procedures | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

131. Inspections | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 9 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RADIOCOMMUNICATIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

132. Definitions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

133. Exclusions from Part 9 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

134. Equivalents and exemptions. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

135. Functional requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

136. Installation, location and control of radio equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

137. Radio equipment to be provided for all sea areas | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

138. Additional radio equipment to be provided for sea areas A1 and A2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

139. Additional radio equipment to be provided for sea areas A1, A2 and A3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

140. Radio watches | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

141. Sources of energy | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

142. Performance standards | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

143. Serviceability and maintenance requirements | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

144. Radio personnel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

145. Radio records | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 10 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SHIPBORNE NAVIGATIONAL EQUIPMENT AND ARRANGEMENTS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

146. Shipborne navigational equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

147. Nautical instruments and publications | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

148. Signalling equipment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

149. Navigating bridge visibility | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 11 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CREW ACCOMMODATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150. General | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

151. Lighting, heating and ventilation | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

152. Sleeping rooms | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

153. Mess rooms | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

154. Sanitary facilities | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

155. Potable water facilities | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

156. Provision stores | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

157. Cooking facilities | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CERTIFICATES AND RECORD OF EQUIPMENT FISHING VESSEL SAFETY CERTIFICATEFISHING VESSEL EXEMPTION CERTIFICATERECORD OF EQUIPMENT | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE 2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

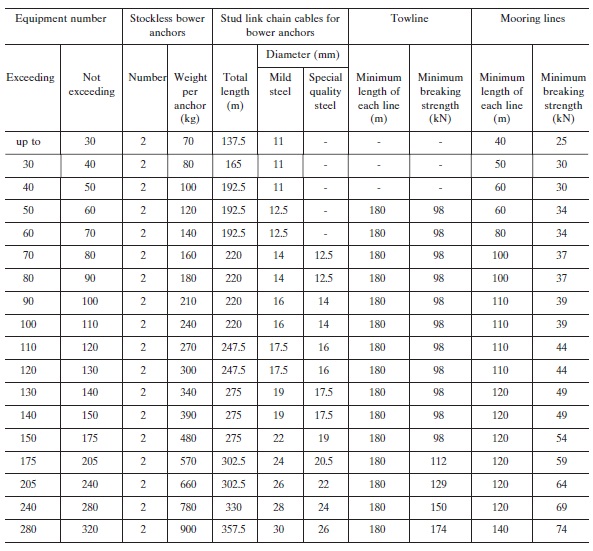

RECOMMENDED PRACTICE FOR ANCHOR AND MOORING EQUIPMENT | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE 3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

INFORMATION AS TO STABILITY OF FISHING VESSELS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE 4 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

AMMONIA REFRIGERATION SYSTEMS IN MANNED SPACES | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE 5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RADIO EQUIPMENT TESTS AND RESERVE POWER CHECKS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE 6 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RADIO LOG | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE 7 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PUBLICATIONS, DIRECTIONS AND INFORMATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MERCHANT SHIPPING (SAFETY OF FISHING VESSELS) (15-24 METRES) REGULATIONS 2007 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Notice of the making of this Statutory Instrument was published in | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“Iris Oifigiúil” of 21st September, 2007. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

I, NOEL DEMPSEY, Minister for Transport, in exercise of the powers conferred on me by section 19 (inserted by section 47 of the Maritime Safety Act 2005 (No. 11 of 2005)) of the Merchant Shipping Act 1992 (No. 2 of 1992) and the Maritime Transport, Safety and Security (Transfer of Departmental Administration and Ministerial Functions) Order 2005 ( S.I. No. 842 of 2005 ), hereby make the following regulations: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GENERAL | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Citation and commencement. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. (1) These Regulations may be cited as the Merchant Shipping (Safety of Fishing Vessels) (15-24 Metres) Regulations 2007. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) These Regulations come into operation— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) on 1 October 2007, for new vessels, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) on 1 October 2008, for existing vessels the keel of which was laid or which was at a similar stage of construction on or after 1 October 1997, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) on 1 October 2009, for existing vessels the keel of which was laid or which was at a similar stage of construction on or after 1 October 1987, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(d) on 1 October 2010, for existing vessels the keel of which was laid or which was at a similar stage of construction before 1 October 1987. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Application. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2. These Regulations apply to every mechanically propelled fishing vessel of 15 metres in length overall (L oa ) and over but less than 24 metres in length (L), registered in the State. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Definitions. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3. In these Regulations— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“amidships” means the mid-length of L; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“approved” means approved by the Minister, or approved in accordance with the standards as set out in the European Communities (Marine Equipment) Regulations 2003 ( S.I. No. 38 of 2003 ); | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“authorised officer” means— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) a surveyor of ships under section 724 of the Merchant Shipping Act 1894 or a recognised organisation; or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) a person, appointed under Regulation 7(11); | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“baseline” means the horizontal line intersecting at amidships the keel line; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“breadth (B)” means the maximum breadth of the vessel, measured amidships to the moulded line of the frame in a vessel with a metal shell and to the outer surface of the hull in a vessel with a shell of any other material; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“collision bulkhead” means a watertight bulkhead up to the working deck in the forepart of the vessel, which meets the following conditions— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) the bulkhead shall be located at a distance from the forward perpendicular not less than 0.05L+0.8m and not more than 0.05L+1.35m, except as may be allowed by the Minister, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) where any part of the underwater body extends forward of the forward perpendicular, for example a bulbous bow, the distance stipulated in paragraph (a) of this definition shall be measured from a point at mid-length of the extension forward of the forward perpendicular or from a point 0.015(L) forward of the forward perpendicular, whichever is less, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) the bulkhead may have steps or recesses provided they are within the limits specified in paragraph (a); | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“crew” means the skipper and all persons employed or engaged in any capacity on board a vessel on the business of that vessel; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“decked vessel” means a vessel having a fixed structural deck covering the entire hull above the deepest operating waterline. Where open wells or cockpits are fitted in this deck the vessel is considered a decked vessel if flooding of the well or cockpit will not endanger the vessel; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“deck erection” means any decked structure on the working deck; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“deepest operating waterline” means the waterline related to the maximum permissible operating draft; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“depth (D)” is the moulded depth amidships; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“enclosed superstructure” means a superstructure with— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) enclosing bulkheads of efficient construction, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) access openings, if any, in those bulkheads fitted with permanently attached weathertight doors of a strength equivalent to the un-pierced structure which can be operated from each side, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) other openings in sides or ends of the superstructure fitted with efficient weathertight means of closing. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

A raised quarter-deck is deemed to be an enclosed superstructure. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

A bridge or poop shall not be regarded as enclosed unless access is provided for the crew to reach machinery and other working spaces inside those superstructures by alternative means which are available at all times when bulkhead openings are closed; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“existing vessel” means a fishing vessel which is not a new vessel; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“fishing vessel” means a vessel designed, equipped or used commercially for catching or taking fish or other living resources of the sea (including the sea bed) or freshwater; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“Fishing Vessel Exemption Certificate” means a certificate issued under Regulation 9(3); | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“Fishing Vessel Safety Certificate” means a certificate granted under Regulation 9(1); | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“freeboard (f)” means the minimum freeboard and is the distance from the underside of the working deck at the side to a waterline, measured perpendicularly to the waterline, plus the minimum thickness of decking. When the working deck is stepped, the lowest line of the deck and the continuation of that line parallel to the upper part of the deck are to be taken as the working deck; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“height of a superstructure or other erection” means the least vertical distance measured at side from the top of the deck beams of a superstructure or an erection to the top of the working deck beams; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“IMO” means International Maritime Organization; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“keel line” means the line parallel to the slope of keel passing amidships through— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) the top of the keel or line of intersection of the inside of shell plating with the keel where a bar keel extends above that line of a vessel with a metal shell, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) the rabbet lower line of the keel of a vessel with a shell of wood or a composite material, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) the intersection of a fair extension of the outside of the shell contour at the bottom with the centreline of a vessel with a shell of material other than wood and metal; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“length (L)” means 96 per cent of the total length on a waterline at 85 per cent of the least depth, or the length from the foreside of the stem to the axis of the rudder stock on that waterline, if that length is greater. In vessels designed with rake of keel the waterline on which this length is measured shall be parallel to the designed waterline; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“length overall (Loa)” means the length measured on a straight line from the fore part of the stem at top to the aftermost side of the transom or stern contour; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“Marine Survey Office” means Marine Survey Office of the Department of Transport; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“moulded depth” means— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) the depth measured from the keel line to the top of the working deck beam at side, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) in vessels having rounded gunwales, the moulded depth measured to the point of intersection of the moulded lines of the deck and side shell plating, the lines extending as though the gunwale were of angular design, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) where the working deck is stepped and the raised part of the deck extends over the point at which the least depth is to be determined, the least depth measured to a line of reference extending from the lower part of the deck along a line parallel with the raised part; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“new vessel” means a vessel the keel of which is laid or which is at a similar stage of construction on or after 1 October 2007; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“a similar stage of construction” means the stage at which— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) construction identifiable with a specific vessel begins, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) assembly of that vessel has commenced comprising at least 50 tonnes or 1 per cent of the estimated mass of all structural material, whichever is the lesser; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“perpendiculars” means the forward and after perpendiculars. Forward and after perpendiculars shall be taken at the forward and after ends of the length (L). The forward perpendicular shall be coincident with the foreside of the stem on the waterline on which the length is measured; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“Protocol” means the Torremolinos International Convention for the Safety of Fishing Vessels 1977, as modified by the Torremolinos Protocol of 1993; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“recognised organisation” means an organisation or other private body carrying out safety assessment work on behalf of the Minister and recognised in conformity with the European Communities (Ship Inspection and Survey Organisations) Regulations 2003 ( S.I. No. 301 of 2003 ); | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“skipper” means a crew member who commands a vessel or has responsibility for it; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“SOLAS” means the annex to the International Convention for the Safety of Life at Sea, 1974, which was adopted by the International Conference on Safety of Life at Sea on 1 November 1974 and entered into force on the 25 May 1980; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“steel or other equivalent material” means steel or any material which, by itself or due to insulation provided, has structural and integrity properties equivalent to steel at the end of the applicable fire exposure to the standard fire test (e.g. aluminium alloy with appropriate insulation); | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“superstructure” means the decked structure on the working deck extending from side to side of the vessel or with the side plating not being inboard of the shell plating more than 0.04B; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“superstructure deck” means that complete or partial deck forming the top of a superstructure, deckhouse or other erection situated at a height of not less than 1.8m above the working deck. Where this height is less than 1.8m, the top of such deck erections shall be treated in the same way as the working deck; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“watertight” means capable of preventing the passage of water through the structure in any direction under a head of water for which the surrounding structure is designed; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“weathertight” means that in any sea conditions water will not penetrate into the vessel; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

“working deck” means the lowest complete deck above the deepest operating waterline from which fishing is undertaken. In vessels fitted with two or more complete decks, a lower deck may be accepted as a working deck provided that that deck is situated above the deepest operating waterline. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Exemptions and equivalents. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4. (1) Where these Regulations require that a particular fitting, material, appliance or apparatus, or type thereof, shall be fitted or carried in a fishing vessel, or that any particular provision shall be made, the Minister may allow any other fitting, material, appliance or apparatus, or type thereof to be fitted, or any other provision to be made in that vessel, if he or she is satisfied that that other fitting, material, appliance or apparatus, or type thereof, or provision, is at least as effective as that required by these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The Minister may, on such conditions as he or she thinks fit, exempt any fishing vessel constructed before the commencement of these Regulations from any of the requirements of these Regulations, if he or she is satisfied that the requirement is either impracticable or unreasonable in the case of such vessel. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Maintenance and upkeep. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5. The hull, machinery, equipment and radio installations as well as crew accommodation of every new vessel shall be constructed and installed so as to be capable of being regularly maintained to ensure that they are at all times, in all respects, satisfactory for the vessel’s intended service. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Repairs, alterations and modifications. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6. (1) A vessel, which undergoes repairs, alterations, modifications and outfitting related to it, shall continue to comply with the requirements previously applicable to that vessel. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Repairs, alterations and modifications of a major character and outfitting related to a vessel shall meet the requirements for a new vessel only to the extent of such repairs, alterations and modifications and in so far as they are reasonable and practicable. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surveys. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7. (1) Every vessel shall be subject to the following surveys— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) an initial survey before the vessel is put into service or before a Fishing Vessel Safety Certificate is issued for the first time, which shall— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) include a complete survey of its structure, stability, machinery, fittings, arrangements and material, including the outside of the vessel’s hull and the inside and outside of the boilers and equipment in so far as the vessel is covered by these Regulations, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) be such as to ensure that the arrangements, materials, and scantlings of the structure, boilers, and other pressure vessels and their appurtenances, main and auxiliary machinery, electrical installations, radio installations including those used in life-saving appliances, fire protection, fire safety systems and appliances, life-saving appliances and arrangements, ship borne navigation equipment, nautical publications and other equipment fully comply with the requirements of these Regulations, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(iii) be such as to ensure that the workmanship of all parts of the vessel and its equipment is in all respects satisfactory and that the vessel is provided with the lights, means of making sound signals and distress signals, required by these Regulations and the International Regulations for Preventing Collisions at Sea currently in force, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(iv) be surveyed, where pilot transfer arrangements are carried, to ensure that they are in a safe working condition and comply with the requirements of SOLAS, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) periodical surveys at the following intervals— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) 4 years with regard to the structure, including the outside of the vessel’s hull, and machinery of the vessel referred to in Parts 2, 3, 4, 5 and 6. As provided for in Regulation 11 the period may be extended for one year subject to the vessel being surveyed internally or externally as far as it is reasonable and practicable, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) 2 years with regard to the equipment of the vessel referred to in Parts 2, 3, 4, 5, 6, 7 and 10, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(iii) 2 years with regard to the radio installations, including those used in life-saving appliances, of the vessel referred to in Parts 7, 9 and 10. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Periodical surveys shall ensure that the appropriate items referred to in paragraph (1)(a) fully comply with the applicable requirements of these Regulations, that the equipment is in good working order and that the stability information is readily available on board. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) In addition to the periodical survey required in paragraph (1)(b)(i), intermediate surveys with regard to the structure and machinery of the vessel at intervals of 2 years shall be carried out. The survey shall ensure that alterations, which would adversely affect the safety of the vessel or the crew, have not been made. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) The owner and skipper of a vessel, the subject of a survey under paragraph (1), shall ensure that the survey is carried out of the vessel. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Application for a survey of a vessel under paragraph (1) shall be made to the Marine Survey Office of the Department by or on behalf of the owner of the vessel. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) A survey of a vessel shall be carried out by an authorised officer. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) An authorised officer— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) shall survey a vessel, after such plans, drawings, specifications, documents and other information, as the authorised officer may require, have been provided by the owner of the vessel, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) in order to ascertain whether a vessel complies with the requirements of these Regulations as apply to it, may require the vessel and any of it’s machinery, fittings and equipment to be submitted to such tests as he or she considers necessary, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) if satisfied, after a periodical survey or intermediate survey, that the vessel complies with the relevant requirements of these Regulations, shall endorse a record of the survey in the space provided on a Fishing Vessel Safety Certificate and shall certify that the vessel was found to comply with the relevant requirements of these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(8) In the cases of vessels classed with a recognised organisation, a surveyor appointed by that recognised organisation may survey the vessel in order to ascertain whether the vessel complies with such requirements of Parts 2 and 4 to it and for that purpose the surveyor may require the vessel and any of its machinery, fittings and equipment to be submitted to such tests as he or she considers necessary. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(9) (a) An authorised officer may for the purpose of a survey under this Regulation— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) board a vessel, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) inspect and examine the vessel, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(iii) inspect and take copies of, or extracts from, records or documents pertaining to the vessel or its owner found on the vessel, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(iv) request any member of the crew of the vessel to furnish him or her with such information and to produce to him or her such records and documents in his or her possession or within his or her procurement, as he or she may reasonably require for the purpose of such functions, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(v) detain the vessel at the place where it is found or direct that it be taken to the nearest convenient port if, in the opinion of the authorised officer, the vessel is in contravention of these Regulations and that the vessel is unfit to proceed on any voyage or excursion because of the danger to human life, or the marine environment, that the voyage or excursion would entail. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) When an authorised officer determines that the condition of the vessel or its equipment does not correspond substantially with the particulars of the Fishing Vessel Safety or Exemption Certificate relating to the vessel or is such that the vessel is not fit to proceed to sea without danger to the vessel, or persons on board, such authorised officer shall immediately direct that corrective action is taken and shall in due course notify the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) Where corrective action is not taken or not taken to the satisfaction of an authorised officer the relevant Fishing Vessel Safety Certificate shall be withdrawn and the Minister shall be notified immediately, and, if the vessel is in the port of another State, the appropriate authorities of the port State shall also be notified immediately. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(10) (a) The condition of the vessel and its equipment shall be maintained to conform with these Regulations to ensure that the vessel in all respects will remain fit to proceed to sea without danger to the vessel or persons on board. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) After any survey of the vessel under this Regulation has been completed, no change shall be made to the structural arrangements, machinery, equipment and other items covered by the survey, without the approval of the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) Whenever an accident occurs to a vessel or a defect is discovered, either of which affects the safety of the vessel or the efficiency or completeness of its life-saving appliances or other equipment- | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) the skipper or owner of the vessel shall report at the earliest opportunity to the Marine Survey Office, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) which office shall decide whether a survey, as required by this Regulation, is necessary, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(iii) if the vessel is in a port of another State, the skipper or owner shall also report immediately to the appropriate authorities of the port State. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(11) The Minister may appoint in writing a person or a member of a class of persons to be an authorised officer for the purposes of these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surveyor’s report and declaration of survey. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8. (1) On completion of a survey under Regulation 7 for the grant or renewal of a Fishing Vessel Safety Certificate, the authorised officer concerned shall provide the Minister with a declaration of survey. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) An authorised officer shall complete and append to the declaration of survey a record of particulars and report in a format specified by the Minister. Such particulars may be given by attaching to the record of a survey a copy of the surveyor’s report and associated plans and documents, if any, and specifying in the record passages in the report in which the relevant particulars are given. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Two copies of the record shall be sent to the owner of the vessel on the initial survey of the vessel which shall be produced for inspection and the addition of the surveyor’s report at subsequent surveys. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fishing Vessel Safety Certificates and exemption certificates. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

9. (1) If the Minister is satisfied that the vessel has been duly surveyed in accordance with these Regulations and— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) complies with the applicable requirements of these Regulations, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) is properly provided with the lights, shapes and means of making sound signals required by the International Regulations for Prevention of Collision at Sea, a Fishing Vessel Safety Certificate, in the form set out in Schedule 1, shall be granted to the owner of the vessel. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) A Fishing Vessel Safety Certificate shall be subject to such conditions and restrictions, if any, as the Minister may impose, at the time of the grant of the certificate or subsequently, and any such conditions or restrictions shall be specified in the certificate or in another document given or sent to the holder of the certificate by the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) When an exemption is granted in accordance with Regulation 4 a Fishing Vessel Exemption Certificate shall be issued in respect of the vessel in addition to the Fishing Vessel Safety Certificate relating to the vessel. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Whenever a certificate under this Regulation is in force in relation to a vessel, the certificate or a copy of it shall be displayed in the vessel in a position in which it is visible and legible to persons on board. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) A Fishing Vessel Safety Certificate and any extension to it or a Fishing Vessel Exemption Certificate shall be issued or endorsed by an authorised officer. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) A Fishing Vessel Safety Certificate shall include a record of equipment in the vessel, in the form set out in Schedule 1, attached to the certificate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) A certificate under this Regulation may be issued by an authorised officer. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Duration of Fishing Vessel Safety Certificate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10. (1) Except as otherwise provided in Regulation 11, a Fishing Vessel Safety Certificate shall be in force for 48 months— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) from the date of completion of the survey of the vessel to which the certificate relates or, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) in the case of a fishing vessel other than a new fishing vessel, from the last examination of the full or underwater fittings in dry dock or from the completion of the radio survey whichever is sooner, or such shorter period as may be specified in the certificate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) A Fishing Vessel Exemption Certificate shall not be valid for longer than the period of the validity of the certificate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extension of Fishing Vessel Safety Certificate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11. (1) A Fishing Vessel Safety Certificate shall not be extended for more than one year subject to the periodical surveys as required in Regulation 7, except as provided for in paragraphs (2) and (3). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) If at the time when the validity of its Fishing Vessel Safety Certificate expires or ceases, a vessel is not in a port at which it can be surveyed, the validity of the certificate may be extended for a period not exceeding 2 months, but such extension shall be granted only for the purpose of allowing the vessel to complete its voyage to the port in which it is to be surveyed, and then only in cases where it appears proper and reasonable to do so. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) A vessel to which such extension is granted shall not, on its arrival in the port in which it is to be surveyed, be entitled by virtue of such extension to leave the port without having obtained a new Fishing Vessel Safety Certificate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) A Fishing Vessel Safety Certificate, which has not been extended under paragraph (1), may be extended for a period of grace up to one month from the date of expiry stated on it. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) No extension under this Regulation has effect for the purposes of these Regulations unless particulars of the date to which the period of validity is extended, together with particulars of the place at and the date on which such extension was given, are endorsed on the current certificate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) The period of validity of any Fishing Vessel Safety Certificate coming into force immediately on the expiry of a certificate extended under this Regulation shall not exceed a period of 4 years, dated to correspond with the original Fishing Vessel Safety Certificate before such an extension. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cancellation of certificates and cesser. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12. (1) The Minister may cancel a Fishing Vessel Safety Certificate or a Fishing Vessel Exemption Certificate if he or she is satisfied that— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) any declaration of survey on which the certificate was founded has been in any particular manner made fraudulently or erroneously, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) the certificate has been issued upon false or erroneous information, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) since the making of the declaration, the hull, equipment or machinery has sustained any damage or are otherwise inadequate for their intended service, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(d) the certificate being extended under Regulation 11 is not endorsed in the manner set out in Regulation 11(5), | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(e) the vessel has ceased to be entered in the Register of Fishing Boats, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(f) corrective action has not been taken under Regulation 7(9)(b) or has not been taken to the satisfaction of an authorised officer. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Where the holder of a Fishing Vessel Safety or Exemption Certificate is notified of the cancellation of the certificate, he or she shall surrender the certificate to the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The following instruments, insofar as they apply to fishing vessels to which these Regulations apply cease to have effect for those vessels in accordance with Regulation 1(2), that is to say: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) the Merchant Shipping (Fire Appliances) Rules 1967 ( S.I. No. 101 of 1967 ), | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) the Merchant Shipping (Life-Saving Appliances) Rules 1967 ( S.I. No. 100 of 1967 ), | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) the Fishing Vessel (Radio Installations) Regulations 1998 ( S.I. No. 544 of 1998 ), | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(d) the Fishing Vessel (Radio Installations Survey) Regulations 1999 ( S.I. No. 40 of 1999 ), | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(e) the Safety, Health and Welfare at Work (Fishing Vessels) Regulations 1999 ( S.I. No. 325 of 1999 ), and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(f) the Merchant Shipping (Musters) (Fishing Vessels) Regulations 1993 ( S.I. No. 43 of 1993 ). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART 2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CONSTRUCTION, WATERTIGHT INTEGRITY AND EQUIPMENT | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Construction. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

13. (1) The strength and construction of the hull, superstructures, deck-houses, machinery casings, companionways and any other structures and the vessel’s equipment shall be sufficient to withstand all foreseeable conditions of the intended service and shall be in accordance with the rules of a recognised organisation or, in the case of an existing vessel, to the satisfaction of the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The hull of vessels intended for operation in ice shall be strengthened in accordance with the anticipated conditions of navigation and area of operation. Wooden vessels, operating from harbours subject to freezing shall have appropriate ice protection sheathing. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Bulkheads, closing devices and closures of openings in these bulkheads, as well as methods for their testing, shall be in accordance with the rules of a Recognised Organisation or other such body acceptable to the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Vessels constructed of material other than wood shall be fitted with a collision bulkhead and at least with watertight bulkheads bounding the main machinery space. Such bulkheads shall be extended up to the working deck. In vessels constructed of wood such bulkheads, which as far as practicable shall be watertight, shall also be fitted. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) The Minister may accept the bulkhead arrangement of an existing vessel provided that such arrangement continues to remain effective in service. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) Pipes piercing the collision bulkhead shall be fitted with suitable valves operable from above the working deck and the valve chest shall be secured at the collision bulkhead inside the forepeak. The valves may be fitted on the after side of the collision bulkhead provided that the valves are readily accessible under all service conditions and the space in which they are located is not a cargo space. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) No door, manhole, ventilation duct or any other opening shall be fitted in the collision bulkhead below the working deck. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(8) The number of openings in the collision bulkhead above the working deck shall be reduced to the minimum compatible with the design and normal operation of the vessel. Such openings shall be capable of being closed weathertight. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(9) The forepeak shall not be used for carrying fuel oil. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Watertight doors. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14. (1) The number of openings in watertight bulkheads required by Regulation 13(3) shall be the minimum compatible with the general arrangement and operational needs of the vessel. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Openings shall be fitted with watertight closing appliances complying with the rules of a recognised organisation or other such body acceptable to the Minister or, in the case of existing vessels, to the satisfaction of the Minister. Watertight doors shall be of an equivalent strength to the adjacent unpierced structure. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Watertight doors may be of the hinged type, and shall be capable of being operated locally from each side of the door. A notice shall be attached to the door on each side stating that the door shall be kept closed at sea. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Sliding watertight doors shall be capable of being operated when the vessel is listed up to 15° either way. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hull integrity. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

15. (1) External openings shall be capable of being closed so as to prevent water from entering the vessel. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) (a) Deck openings, which may be open during fishing operations, shall be arranged near to the vessel’s centreline. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) The Minister may approve different arrangements provided that the safety of the vessel will not be impaired. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Fish flaps on stern trawlers shall be power-operated and capable of being controlled from any position which provides an unobstructed view of the operation of the flaps. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weathertight doors. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16. (1) All access openings in bulkheads of enclosed superstructures and other outer structures, through which water could enter and endanger the vessel, shall be fitted with doors permanently attached to the bulkhead, framed and stiffened so that the whole structure is of equivalent strength to the unpierced structure, and weathertight when closed. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The means for securing these doors weathertight shall consist of gaskets and clamping devices or other equivalent means and shall be permanently attached to the bulkhead or to the doors themselves, and shall be so arranged that they can be operated from each side of the bulkhead. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The height above deck of sills in those doorways, in companionways, erections and machinery casings which give direct access to parts of the deck exposed to the weather and sea shall be at least 600mm on the working deck and at least 300mm on the superstructure deck. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Where operating experience has shown justification and, on the approval of the Minister, these heights, except in the doorways giving direct access to machinery spaces, may be reduced to not less than 380mm and 150mm respectively. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hatchways closed by wood covers. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17. (1) The height above deck of hatchway coamings on exposed parts of the working deck shall be: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The height above deck of hatchway coamings on exposed parts of the superstructure deck shall be at least 300mm. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Where operating experience has shown justification and on the approval of the Minister, the height of hatchway coamings, except those which give direct access to machinery spaces, may be reduced from the height as specified in paragraph (1) or the coamings may be omitted entirely, provided that efficient watertight hatch covers other than wood are fitted. Such hatchways shall be kept as small as practicable and the covers shall be permanently attached by hinges or equivalent means and be capable of being rapidly closed or battened down. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The finished thickness of wood hatchway covers shall include an allowance for abrasion due to rough handling. The finished thickness of these covers shall be at least 4mm for each 100mm of unsupported span subject to a minimum of 40mm and the width of their bearing surfaces shall be at least 65mm. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Where wooden hatchway covers are fitted they shall be capable of being secured weathertight. Arrangements for securing wood hatchway covers weathertight shall be provided. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hatchways closed by covers other than wood. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18. (1) (a) The height above deck of hatchway coamings shall be as specified in Regulation 17(1). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Where operating experience has shown justification and on the approval of the Minister, the height of these coamings may be reduced, or the coamings omitted entirely, provided that the safety of vessels is not impaired by such omission. In this case, the hatchway openings shall be kept as small as practicable and the covers be permanently attached by hinges or equivalent means and be capable of being rapidly closed and battened down, or by equally effective arrangements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) For the purpose of strength calculations it shall be assumed that hatchway covers are subjected to static loads of 10 kN/m2, or the weight of cargo intended to be carried on them, whichever is the greater. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Where a hatchway is situated on the superstructure deck in a position abaft a point 0.25 of the length from the forward perpendicular, the assumed loads may be reduced to not less than 75 per cent of the requirement of paragraph (2). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Where covers are made of mild steel, the maximum stress calculated according to paragraph (2) multiplied by 4.25 shall not exceed the minimum ultimate strength of the material. Under these loads the deflections shall not be more than 0.0028 times the span. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Covers made of materials other than mild steel shall be at least of equivalent strength to those made of mild steel and their construction shall be of sufficient stiffness to ensure weathertightness under the loads specified in paragraph (2). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) Covers shall be fitted with clamping devices and gaskets or other equivalent arrangements sufficient to ensure weathertightness. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machinery space openings. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

19. (1) Machinery space openings shall be framed and enclosed by casings of strength equivalent to the adjacent superstructure. External access openings therein shall be fitted with doors complying with Regulation 16 or with hatch covers other than wood complying with Regulation 18. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Openings other than access openings shall be fitted with covers of equivalent strength to the unpierced structure, permanently attached thereto and capable of being closed weathertight. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Where casings are not fitted the access openings to the machinery space shall be closed in accordance with the provisions of paragraph (1). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Other deck openings. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20. (1) Where it is essential for fishing operations, flush deck scuttles of the screw, bayonet or equivalent type, and manhole covers may be fitted, provided these are capable of being closed watertight and such devices shall be permanently attached to the adjacent structure. Subject to the approval of the Minister, and having regard to the size and disposition of the openings and the design of the closing devices, metal-to-metal closures may be fitted provided that they are effectively watertight. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) An efficient deck erection or companionway, fitted with weathertight doors or their equivalent, shall be provided to protect openings, other than hatchways, machinery space openings, manholes and flush scuttles in the working deck. Companionways shall be situated as close as practicable to the vessel’s centreline. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ventilators. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

21. (1) The coamings of ventilators shall be as high as practicable. On the working deck the height above deck of coamings of ventilators other than machinery space ventilators shall be not less than 760mm and on superstructure decks not less than 450mm. When the height of such ventilators may interfere with the working of the vessel their coaming heights may be reduced to the satisfaction of the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Machinery space ventilators shall be led as high as is reasonable and practicable and preferably be fitted well inboard; the angle of initial down flooding to the machinery spaces shall not be less than 40°. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) (a) Coamings of ventilators shall be of equivalent strength to the adjacent structure and capable of being closed weathertight by devices permanently attached to the ventilator or adjacent structure. Where the coaming of any ventilator exceeds 900mm in height it shall be specially supported. Ventilators shall be arranged as close to the vessel’s centreline as possible and, where practicable, shall extend through the top of a deck erection or companionway. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Closing appliances need not be fitted to ventilators the coamings of which extend more than 3.4 metres above the working deck or more than 1.7 metres above a deckhouse top or superstructure deck. If it is unlikely that water will enter the vessel through machinery space ventilators, closing appliances to such ventilators may be omitted, subject to the approval of the Minister. Fire flaps shall be fitted to such coamings in accordance with Regulation 82. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air pipes. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

22. (1) Where air pipes to tanks and void spaces below deck extend above the working or superstructure decks, the exposed parts of the pipes shall be of strength equivalent to the adjacent structures and fitted with appropriate protection and, as far as is practicable, located close to the vessel’s centreline and protected from damage by fishing or lifting gear. Openings of pipes shall be provided with means of closing, permanently attached to the pipe or adjacent structure, except that where they are protected against water trapped on deck, these means of closing may, subject to the approval of the Minister, be omitted. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The height of air pipes above deck to the point where water may have access below shall be at least 760mm on the working deck and at least 450mm on the superstructure deck. To avoid interference with the fishing operations the Minister may accept a reduction of the height of an air pipe. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sounding devices. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

23. (1) Sounding devices shall be fitted to- | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) the bilges of those compartments which are not readily accessible at all times during the voyage, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) all tanks and cofferdams. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Where sounding pipes are fitted— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) their upper ends shall be extended to a readily accessible position and, where practicable, above the working deck, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) their openings shall be provided with permanently attached means of closing, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) shall be fitted with automatic self-closing devices in sounding pipes which are not extended above the working deck. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Sounding arrangements on fuel service tanks shall be such that in the event of the tanks being overfilled, spillage through the means of sounding cannot occur. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Fuel tank sounding pipe openings shall not be located in crew accommodation. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sidescuttles and windows. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24. (1) Sidescuttles to spaces below the working deck and to enclosed spaces on the working deck shall be fitted with hinged deadlights capable of being closed watertight. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) No sidescuttle shall be fitted in such a position that its sill is less than 500mm above the deepest operating waterline. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Sidescuttles fitted less than 1000mm above the deepest operating waterline shall be of the fixed type. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Windows, sidescuttles and skylights, together with their frames, glasses and deadlights, shall be of an approved construction. Those prone to be damaged by fishing gear shall be suitably protected. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) (a) Skylights leading to spaces below the working deck shall be of substantial construction and capable of being closed and secured weathertight, and with provision for adequate means of closing in the event of damage to the inserts. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Skylights leading to machinery spaces shall be avoided as far as practicable. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) (a) Toughened safety glass or suitably permanently transparent material of equivalent strength shall be fitted in all wheelhouse windows exposed to the weather. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) The means of securing windows and the width of the bearing surfaces shall be adequate, having regard to the window material used. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) Openings leading to spaces below deck from a wheelhouse whose windows are not provided with the protection required by paragraph (7) shall be fitted with a weathertight closing appliance. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) Deadlights or a suitable number of storm shutters shall be provided where there is no other method of preventing water from entering the hull through a broken window or sidescuttle. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(8) If the safety of the vessel is not impaired, sidescuttles and windows without deadlights in side or aft bulkheads of deck erections located on or above the working deck may be accepted, subject to the approval of the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||