S.I. No. 374/2004 - European Communities (Transportable Pressure Equipment) Regulations 2004

Regulation | ||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||

SCHEDULES | ||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||

S.I. No. 374 of 2004. | ||||||||||||||||||||||||||||||||||||||||||||

EUROPEAN COMMUNITIES (TRANSPORTABLE PRESSURE EQUIPMENT) REGULATIONS 2004. | ||||||||||||||||||||||||||||||||||||||||||||

I, MARY HARNEY, Minister for Enterprise, Trade and Employment, in exercise of the powers conferred on me by section 3 of the European Communities Act, 1972 (No. 27 of 1972), and for the purposes of giving effect to Council Directive 1999/36/EC of 29 April 19991 as amended and adapted to technical progress by Commission Directive 2001/2/EC of 4 January 20012 and Commission Directive 2002/50/EC of 6 June 20023 , hereby make the following regulations: | ||||||||||||||||||||||||||||||||||||||||||||

|

Citation | 1. These Regulations may be cited as the European Communities (Transportable Pressure Equipment) Regulations 2004. | |||||||||||||||||||||||||||||||||||||||||||

|

Interpretation | 2. (1) In these Regulations— | |||||||||||||||||||||||||||||||||||||||||||

“ADR” means the provisions which came into effect on 1 January 2003 concerning the international carriage of dangerous goods by road which— | ||||||||||||||||||||||||||||||||||||||||||||

(a) form Annexes A and B to the European Agreement concerning the International Carriage of Dangerous Goods by Road (version applicable as from 1 January 20034 ); | ||||||||||||||||||||||||||||||||||||||||||||

(b) are contained in Annexes A and B to the ADR Directive; | ||||||||||||||||||||||||||||||||||||||||||||

“ADR Directive” means Council Directive 94/55/EC of 21 November, 19945 on the approximation of the laws of the Member States with regard to the transport of dangerous goods by road, as amended by Directive 2000/61/EC of the European Parliament and of the Council of 10 October 20016 and Commission Directive 2003/28/EC of 7 April 20037 . | ||||||||||||||||||||||||||||||||||||||||||||

“aerosol dispenser” has the meaning in Chapter 1.2.1 of ADR in relation to carriage by road or of RID in relation to carriage by rail; | ||||||||||||||||||||||||||||||||||||||||||||

“approved body” shall be construed in accordance with Regulation 9 [check cross reference] and does not include a national approved body; | ||||||||||||||||||||||||||||||||||||||||||||

“battery vehicle” has the meaning in Chapter 1.2.1 of ADR in relation to carriage by road; | ||||||||||||||||||||||||||||||||||||||||||||

“battery wagon” has the meaning in Chapter 1.2.1 of RID in relation to carriage by rail; | ||||||||||||||||||||||||||||||||||||||||||||

“bundles of cylinders” means— | ||||||||||||||||||||||||||||||||||||||||||||

(a) in relation to carriage by road, a “bundle of cylinders” as set out in Chapter 1.2.1 of ADR; | ||||||||||||||||||||||||||||||||||||||||||||

(b) in relation to carriage by rail, a “bundle of cylinders (frame)” as set out in Chapter 1.2.1 of RID; | ||||||||||||||||||||||||||||||||||||||||||||

“CE mark” means the mark referred to in Regulation 18 of the European Communities (Pressure Equipment) Regulations 1999 ( S.I. No. 400 of 1999 ); | ||||||||||||||||||||||||||||||||||||||||||||

“class 2 goods” shall be construed in accordance with Chapter 2.2.2.1.1. of ADR in relation to carriage by road or of RID in relation to carriage by rail; | ||||||||||||||||||||||||||||||||||||||||||||

“competent authority” means the National Authority for Occupational Safety and Health; | ||||||||||||||||||||||||||||||||||||||||||||

“conformity assessment procedures” means the procedures set out in Schedule 2, and “conformity assessment” shall be construed accordingly; | ||||||||||||||||||||||||||||||||||||||||||||

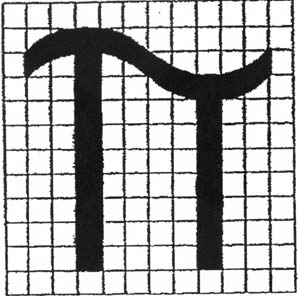

“conformity marking” means the marking referred to in Regulation 11 and set out in Schedule 6; | ||||||||||||||||||||||||||||||||||||||||||||

“COTIF” means the Convention concerning International Carriage by Rail, as revised or reissued from time to time; | ||||||||||||||||||||||||||||||||||||||||||||

“cylinder” has the meaning in Chapter 1.2.1 of ADR in relation to carriage by road or of RID in relation to carriage by rail; | ||||||||||||||||||||||||||||||||||||||||||||

“cryogenic receptacle” has the meaning in Chapter 1.2.1 of ADR in relation to carriage by road or of RID in relation to carriage by rail; | ||||||||||||||||||||||||||||||||||||||||||||

“Minister” means the Minister for Enterprise, Trade and Employment; | ||||||||||||||||||||||||||||||||||||||||||||

“national approved body” means a person appointed by the competent authority pursuant to Regulation 10 [cross ref] for the purposes of Regulation 5 [cross ref]; | ||||||||||||||||||||||||||||||||||||||||||||

“notified body” shall be construed in accordance with Regulation 8; | ||||||||||||||||||||||||||||||||||||||||||||

“owner” means, in relation to a transportable pressure equipment: | ||||||||||||||||||||||||||||||||||||||||||||

(a) subject to sub-paragraphs (b) and (c), the employer or the self-employed person who owns it (other than a person who buys it solely to use the goods therein before returning it to the supplier); | ||||||||||||||||||||||||||||||||||||||||||||

(b) subject to sub-paragraph (c), in the case of a lease, the lessee; or | ||||||||||||||||||||||||||||||||||||||||||||

(c) where the person referred to in sub-paragraph (a) or (b) does not have a place of business in the State: | ||||||||||||||||||||||||||||||||||||||||||||

(i) the agent of that person in the State, or | ||||||||||||||||||||||||||||||||||||||||||||

(ii) if there is no such agent, the user; | ||||||||||||||||||||||||||||||||||||||||||||

“periodic inspection procedures” means the procedures set out in Schedule 5 or, where the context otherwise permits or requires, Annex IV, Part III of the Transportable Pressure Equipment Directive and “periodic inspection” shall be construed accordingly; | ||||||||||||||||||||||||||||||||||||||||||||

“placing on the market” means supplying transportable pressure equipment, or making it available to another person in the Community and includes importation of such equipment, and related expressions shall be interpreted construed accordingly; | ||||||||||||||||||||||||||||||||||||||||||||

“pressure drum” has the meaning in Chapter 1.2.1 of ADR in relation to carriage by road or of RID in relation to carriage by rail; | ||||||||||||||||||||||||||||||||||||||||||||

“reassessment of conformity” means the procedures set out in Schedule 4 for subsequent assessment, at the request of the owner, of the conformity of transportable pressure equipment already manufactured and put into service before 1 July 2001 and “conformity reassessment” shall be construed accordingly; | ||||||||||||||||||||||||||||||||||||||||||||

“receptacle” means a cylinder, tube, pressure drum, cryogenic receptacle or bundles of cylinders as defined in Chapter 1.2.1 of ADR; | ||||||||||||||||||||||||||||||||||||||||||||

“RID” means the regulations which came into effect on 1 January 2003 concerning the international carriage of dangerous goods by rail which— | ||||||||||||||||||||||||||||||||||||||||||||

(a) form Annex 1 to Appendix B to COTIF; | ||||||||||||||||||||||||||||||||||||||||||||

(b) are contained in the Annex to the RID Directive; and | ||||||||||||||||||||||||||||||||||||||||||||

(c) include the 2004 Supplement which came into force on 1 January 20048 ; | ||||||||||||||||||||||||||||||||||||||||||||

“RID Directive” means Council Directive 96/49/EC of 23 July 19969 on the approximation of the laws of the Member States with regard to the transport of dangerous goods by rail as amended by Directive 2000/62 of the European Parliament and the Council of 10 October 200010 and Commission Directive 2003/29/EC of 7 April 200311 . | ||||||||||||||||||||||||||||||||||||||||||||

“separate Directives” means Council Directives 84/525/EEC of 17 September 1984, 84/526/EEC of 17 September 1984 and 84/527 of 17 September 1984 concerning the approximation of laws of the Member States relating to seamless steel gas cylinders, seamless unalloyed aluminium and aluminium alloy gas cylinders, and welded unalloyed steel gas cylinders, respectively12 ; | ||||||||||||||||||||||||||||||||||||||||||||

“tank” has the meaning in Chapter 1.2.1 of ADR in relation to carriage by road or of RID in relation to carriage by rail and includes a demountable tank, tank-container (mobile tank), a tank of tank wagons, a tank of battery vehicles or battery wagons and a tank of tank vehicles; | ||||||||||||||||||||||||||||||||||||||||||||

“transport” means transport by road or on a railway, on a vehicle; | ||||||||||||||||||||||||||||||||||||||||||||

“transportable pressure equipment” means— | ||||||||||||||||||||||||||||||||||||||||||||

(a) a receptacle or tank or battery vehicle or battery wagon which is used or intended to be used for the carriage by road or rail of— | ||||||||||||||||||||||||||||||||||||||||||||

(i) class 2 goods; | ||||||||||||||||||||||||||||||||||||||||||||

(ii) the dangerous substances of other classes specified in Schedule 1 | ||||||||||||||||||||||||||||||||||||||||||||

including any valve or other accessory fitted to the equipment and used for carriage; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) does not include— | ||||||||||||||||||||||||||||||||||||||||||||

(i) equipment subject to the general exemption principles applicable to small quantities and to the special cases provided for in the Annexes to the ADR Directive and the RID Directive; | ||||||||||||||||||||||||||||||||||||||||||||

(ii) an aerosol dispenser; or | ||||||||||||||||||||||||||||||||||||||||||||

(iii) a cylinder used to contain class 2 goods and forming a component part of breathing apparatus; | ||||||||||||||||||||||||||||||||||||||||||||

“Transportable Pressure Equipment Directive” means Council Directive 1999/36/EC of 29 April 19991 concerning the approximation of laws of the Member States relating to common provisions for transportable pressure equipment and methods for inspection, as amended and adapted to technical progress by Commission Directive 2001/2/EC of 4 January 20012 and Commission Directive 2002/50/EC of 6 June 20023 ; | ||||||||||||||||||||||||||||||||||||||||||||

“tube” has the meaning in Chapter 1.2.1. of ADR in relation to carriage by road or of RID in relation to carriage by rail; and | ||||||||||||||||||||||||||||||||||||||||||||

“wagon” has the meaning in Chapter 1.2.1 of RID. | ||||||||||||||||||||||||||||||||||||||||||||

(2) In these Regulations, the words “used at work”, when referring to transportable pressure equipment, include the filling, emptying, refilling, storage and transport of that equipment at work and an intention to conduct any of those activities, and related expressions shall be construed accordingly. | ||||||||||||||||||||||||||||||||||||||||||||

(3) A word or expression that is used in these Regulations and is also used in the Transportable Pressure Equipment Directive has, unless the contrary intention appears, the same meaning in these Regulations as it has in the Directive. | ||||||||||||||||||||||||||||||||||||||||||||

(4) A reference in these Regulations to— | ||||||||||||||||||||||||||||||||||||||||||||

(a) a Regulation or a Schedule is a reference to a Regulation of, or Schedule to, these Regulations, unless it is indicated that reference to some other provision is intended, and | ||||||||||||||||||||||||||||||||||||||||||||

(b) a paragraph or subparagraph is a reference to the paragraph or subparagraph of the provision of which the reference occurs, unless it is indicated that reference to some other provision is intended. | ||||||||||||||||||||||||||||||||||||||||||||

|

Scope | 3. (1) Subject to paragraph (2), these Regulations apply to any transportable pressure equipment placed on the market or used at work and: | |||||||||||||||||||||||||||||||||||||||||||

(a) manufactured on or after 1 July 2001; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) manufactured before 1 July 2001, where that equipment is: | ||||||||||||||||||||||||||||||||||||||||||||

(i) subject to a reassessment of conformity, or | ||||||||||||||||||||||||||||||||||||||||||||

(ii) a cylinder bearing all the marks and inscriptions required by the separate Directives relating to that cylinder. | ||||||||||||||||||||||||||||||||||||||||||||

(2) These Regulations do not apply to: | ||||||||||||||||||||||||||||||||||||||||||||

(a) in the case of pressure drums, bundles of cylinders or tanks, until 1 July 2005; | ||||||||||||||||||||||||||||||||||||||||||||

(b) transportable pressure equipment used exclusively for the transport of dangerous goods between a Member State and third countries carried out in accordance with Article 6(1) and Article 7 of the ADR Directive or Article 6(1) and Article 7(1) and (2) of the RID Directive. | ||||||||||||||||||||||||||||||||||||||||||||

|

Requirements relating to the placing on the market or use at work of new transportable pressure equipment | 4. (1) Subject to Regulation 5, no person shall place on the market or use at work any transportable pressure equipment unless the requirements of paragraphs (2) and (3) have been complied with. | |||||||||||||||||||||||||||||||||||||||||||

(2) Transportable pressure equipment must— | ||||||||||||||||||||||||||||||||||||||||||||

(a) be safe and suitable for its purpose; | ||||||||||||||||||||||||||||||||||||||||||||

(b) in relation to carriage by road, meet the relevant provisions of the ADR Directive and in relation to carriage by rail, meet the relevant provisions of the RID Directive; | ||||||||||||||||||||||||||||||||||||||||||||

(c) have been assessed by a notified body, in accordance with the relevant conformity assessment procedures set out in Schedule 2 and specified in Schedule 3; and | ||||||||||||||||||||||||||||||||||||||||||||

(d) bear the conformity marking, the identification number of the notified body and any marking required pursuant to the ADR Directive and the RID Directive. | ||||||||||||||||||||||||||||||||||||||||||||

(3) Where the transportable pressure equipment includes valves and other accessories that have a direct safety function, those valves and accessories shall be subject to a conformity assessment procedure at least as stringent as that undergone by the receptacle or tank to which they are fitted, and such valves and other accessories used for transport may be subject to a different conformity assessment procedure separate from that used for the receptacle or tank. | ||||||||||||||||||||||||||||||||||||||||||||

(4) Where the ADR Directive and the RID Directive do not contain detailed technical provisions, such valves and accessories must meet the requirements of Directive 97/23/EC of 29 May 199713 and, pursuant to that Directive be subject to a category II, III or IV conformity assessment procedure as laid down in Article 10 thereof according to whether the receptacle or tank belongs to category 1, 2 or 3 as laid down in Schedule 3. | ||||||||||||||||||||||||||||||||||||||||||||

(5) Any technical documentation or other information required to be retained under a conformity assessment procedure shall be retained by the person specified in that procedure for any period specified in that procedure. | ||||||||||||||||||||||||||||||||||||||||||||

|

Transportable pressure equipment placed on the market or used at work exclusively in the State | 5. (1) Regulation 4 shall not apply to a receptacle (including its valves and accessories) which is placed on the market or used at work exclusively within the State provided the requirements of paragraph (2) are complied with. | |||||||||||||||||||||||||||||||||||||||||||

(2) The receptacle (including its valves and accessories) must— | ||||||||||||||||||||||||||||||||||||||||||||

(a) have been designed, manufactured and tested in accordance with the ADR Directive in relation to carriage by road or the RID Directive in relation to carriage by rail; | ||||||||||||||||||||||||||||||||||||||||||||

(b) where relevant, have been assessed by a national approved body, in accordance with the conformity assessment procedures set out in modules A1, C1, F and G in Schedule 2 (and for this purpose, references in those procedures to a “notified body” shall be read as if they are references to a “national approved body”) to be in conformity with the requirements referred to in the ADR Directive and the RID Directive which are applicable to the equipment in question; | ||||||||||||||||||||||||||||||||||||||||||||

(c) not bear the conformity marking or the identification number of any notified body. | ||||||||||||||||||||||||||||||||||||||||||||

(3) In respect of any conformity assessment undertaken pursuant to this Regulation, a national approved body shall work exclusively for the group of which it is a member and in this paragraph and in Schedules 2 to 5 “group” has the same meaning as in the Transportable Pressure Equipment Directive. | ||||||||||||||||||||||||||||||||||||||||||||

(4) Any technical documentation or other information required to be retained under a conformity assessment procedure shall be retained by the person specified in that procedure for any period specified in that procedure. | ||||||||||||||||||||||||||||||||||||||||||||

|

Reassessment of conformity for existing transportable pressure equipment | 6. (1) Transportable pressure equipment which: | |||||||||||||||||||||||||||||||||||||||||||

(a) was manufactured prior to 1 July 2001 in accordance with the ADR Directive in relation to carriage by road or the RID Directive in relation to carriage by rail; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) does not bear the conformity marking | ||||||||||||||||||||||||||||||||||||||||||||

may be reassessed for conformity in accordance with paragraph (2). | ||||||||||||||||||||||||||||||||||||||||||||

(2) Subject to paragraph (3), the transportable pressure equipment must: | ||||||||||||||||||||||||||||||||||||||||||||

(a) comply with the requirements of the ADR Directive in relation to carriage by road or of the RID Directive in relation to carriage by rail; | ||||||||||||||||||||||||||||||||||||||||||||

(b) have been reassessed by a notified body, in accordance with the reassessment of conformity procedure to be in conformity with the requirements referred to in the ADR Directive and the RID Directive which are applicable to the equipment in question; and | ||||||||||||||||||||||||||||||||||||||||||||

(c) bear the conformity marking and the identification number of the notified body. | ||||||||||||||||||||||||||||||||||||||||||||

(3) In the case of receptacles (including their valves and other accessories used for transport) manufactured in series, the reassessment of such receptacles (including their valves and other accessories used for transport) may be conducted by an approved body provided that conformity of the type is reassessed by a notified body. For the purposes of this paragraph, the references in Schedule 4 [confirm cross reference] to “notified body“ shall be read as if they were references to “approved body”. | ||||||||||||||||||||||||||||||||||||||||||||

|

Periodic inspection and repeated use | 7. (1) The owner of transportable pressure equipment shall ensure that the equipment is periodically inspected in accordance with all relevant procedures in Schedule 5 to ensure the continued safety of that equipment and that the equipment continues to meet the requirements to which it was designed and manufactured. | |||||||||||||||||||||||||||||||||||||||||||

(2) A periodic inspection shall: | ||||||||||||||||||||||||||||||||||||||||||||

(a) in the case of a receptacle (including its valves and other accessories used for transport), be carried out by: | ||||||||||||||||||||||||||||||||||||||||||||

(i) a notified body; | ||||||||||||||||||||||||||||||||||||||||||||

(ii) an approved body carrying out an inspection pursuant to the procedures set out in Schedule 5, module 1; or | ||||||||||||||||||||||||||||||||||||||||||||

(iii) an approved body appointed for that purpose carrying out an inspection pursuant to the procedures set out in Schedule 5, module 2 provided it acts under the supervision of a notified body. | ||||||||||||||||||||||||||||||||||||||||||||

(b) in the case of a tank (including its valves and other accessories used for transport) be carried out by: | ||||||||||||||||||||||||||||||||||||||||||||

(i) a notified body; or | ||||||||||||||||||||||||||||||||||||||||||||

(ii) an approved body appointed by the competent authority for that purpose, acting under the supervision of a notified body. | ||||||||||||||||||||||||||||||||||||||||||||

(3) A person who carries out a periodic inspection of transportable pressure equipment shall ensure that— | ||||||||||||||||||||||||||||||||||||||||||||

(a) the inspection complies with the relevant requirements of Schedule 5; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) at the end of the inspection, the equipment is marked with— | ||||||||||||||||||||||||||||||||||||||||||||

(i) the identification number of the relevant notified body or approved body, | ||||||||||||||||||||||||||||||||||||||||||||

(ii) where required by Schedule 5, the date of the inspection, and | ||||||||||||||||||||||||||||||||||||||||||||

(iii) in the case of cylinders marked in accordance with the separate Directives undergoing their first periodic inspection, the conformity marking. | ||||||||||||||||||||||||||||||||||||||||||||

(4) Any technical documentation or other information required to be retained under a periodic inspection procedure shall be retained by the person specified in that procedure for any period specified in that procedure. | ||||||||||||||||||||||||||||||||||||||||||||

(5) Periodic inspections covered by this Regulation may be carried out in any Member State. | ||||||||||||||||||||||||||||||||||||||||||||

|

Notified bodies | 8. For the purposes of these Regulations, a notified body is a body which has been appointed— | |||||||||||||||||||||||||||||||||||||||||||

(a) to carry out one or more of the following: | ||||||||||||||||||||||||||||||||||||||||||||

(i) one or more conformity assessment procedures; | ||||||||||||||||||||||||||||||||||||||||||||

(ii) reassessment of conformity procedures; | ||||||||||||||||||||||||||||||||||||||||||||

(iii) periodic inspection procedures pursuant to periodic inspection procedure, module 1; or | ||||||||||||||||||||||||||||||||||||||||||||

(iv) the task of surveillance pursuant to periodic inspection procedure, module 2; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) as a notified body: | ||||||||||||||||||||||||||||||||||||||||||||

(i) pursuant to Regulation 10; or | ||||||||||||||||||||||||||||||||||||||||||||

(ii) by another Member State, and whose appointment has been communicated by that Member State to the Commission and the other Member States pursuant to Article 8 of the Transportable Pressure Equipment Directive. | ||||||||||||||||||||||||||||||||||||||||||||

|

Approved bodies | 9. (1) For the purposes of these Regulations, an approved body is a body which has been appointed— | |||||||||||||||||||||||||||||||||||||||||||

(a) to carry out one or more of the following: | ||||||||||||||||||||||||||||||||||||||||||||

(i) one or more conformity assessment procedures; | ||||||||||||||||||||||||||||||||||||||||||||

(ii) reassessment of conformity procedures; | ||||||||||||||||||||||||||||||||||||||||||||

(iii) periodic inspection procedures; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) as an approved body: | ||||||||||||||||||||||||||||||||||||||||||||

(i) pursuant to Regulation 10; or | ||||||||||||||||||||||||||||||||||||||||||||

(ii) by another Member State, and whose appointment has been communicated by that Member State to the Commission and the other Member States pursuant to Article 8 of the Transportable Pressure Equipment Directive. | ||||||||||||||||||||||||||||||||||||||||||||

|

Appointment of notified bodies, and approved bodies and national approved bodies by the competent authority | 10. (1) The competent authority may appoint such persons as it thinks fit to be notified bodies, approved bodies or national approved bodies for the purposes of these Regulations. | |||||||||||||||||||||||||||||||||||||||||||

(2) A person shall not be appointed as a notified body or approved body unless, in the opinion of the competent authority, it meets the minimum criteria specified in Schedule 7, Part 1 and | ||||||||||||||||||||||||||||||||||||||||||||

(a) in the case of an applicant for approval as a notified body, the supplementary criteria specified in Schedule 7, Part 2; | ||||||||||||||||||||||||||||||||||||||||||||

(b) in the case of an applicant for approval as an approved body, the supplementary criteria specified in Schedule 7, Part 3. | ||||||||||||||||||||||||||||||||||||||||||||

(3) An application for— | ||||||||||||||||||||||||||||||||||||||||||||

(a) appointment as a notified body; | ||||||||||||||||||||||||||||||||||||||||||||

(b) appointment as an approved body; or | ||||||||||||||||||||||||||||||||||||||||||||

(c) appointment as a national approved body; or | ||||||||||||||||||||||||||||||||||||||||||||

(d) the amendment of an existing appointment, | ||||||||||||||||||||||||||||||||||||||||||||

shall be made to the competent authority. | ||||||||||||||||||||||||||||||||||||||||||||

(4) An appointment made under this Regulation by the competent authority— | ||||||||||||||||||||||||||||||||||||||||||||

(a) may relate to all descriptions of transportable pressure equipment or to such descriptions as the competent authority may determine; | ||||||||||||||||||||||||||||||||||||||||||||

(b) may be made subject to such conditions as the competent authority may determine, and such conditions may include conditions which apply upon or following termination of the appointment; | ||||||||||||||||||||||||||||||||||||||||||||

(c) shall, without prejudice to the generality of subparagraph (b) and subject to paragraph (8), require the notified body, or approved body or national approved body, as the case may be, to carry out the procedures and specific tasks for which it has been appointed including (where so provided as part of those procedures) surveillance to ensure that the manufacturer of the transportable pressure equipment fulfils the obligations arising out of the relevant conformity assessment procedure; | ||||||||||||||||||||||||||||||||||||||||||||

(d) shall be terminated upon 90 days’ notice in writing to the competent authority at the request of the notified body, or the approved body or national approved body; and | ||||||||||||||||||||||||||||||||||||||||||||

(e) may be terminated if it appears to the competent authority that any of the conditions of the appointment are not being complied with. | ||||||||||||||||||||||||||||||||||||||||||||

(5) Subject to paragraph (43)(d) and (e), an appointment under this Regulation may be for the time being, or for such period as may be specified in the appointment. | ||||||||||||||||||||||||||||||||||||||||||||

(6) A notified body, or an approved body or national approved body appointed by the competent authority shall be subject to such inspection by or on behalf of the competent authority as is necessary to ensure compliance with any condition specified in the appointment. | ||||||||||||||||||||||||||||||||||||||||||||

(7) The inspection referred to in paragraph (6) may include the examination of premises, equipment and documents and the notified body, or approved body or national approved body shall provide such copies, facilities, assistance and information as are reasonably required for the purpose of the inspection. | ||||||||||||||||||||||||||||||||||||||||||||

(8) In respect of an application made to a notified body, or an approved body or national approved body in accordance with these Regulations, the notified body, or approved body or national approved body, as the case may be, shall not be required to carry out the procedures and tasks referred to in paragraph (4)(c)— | ||||||||||||||||||||||||||||||||||||||||||||

(a) if the documents submitted to it with the application are not in English or another language acceptable to that body; | ||||||||||||||||||||||||||||||||||||||||||||

(b) until the applicant has paid the fee which that body requires pursuant to Regulation 14 [cross-reference to be checked prior to finalisation]; or | ||||||||||||||||||||||||||||||||||||||||||||

(c) if the body in question reasonably believes that, having regard to the number of applications made to it in relation to its appointment under these Regulations which are outstanding, it will be unable to commence the required work within three months of receiving the application. | ||||||||||||||||||||||||||||||||||||||||||||

(9) If for any reason the appointment of a notified body, or an approved body or national approved body is terminated under this Regulation, the competent authority may— | ||||||||||||||||||||||||||||||||||||||||||||

(a) give such directions: | ||||||||||||||||||||||||||||||||||||||||||||

(i) to the body whose appointment has been terminated; or | ||||||||||||||||||||||||||||||||||||||||||||

(ii) to another notified body, or approved body or national approved body, | ||||||||||||||||||||||||||||||||||||||||||||

for the purpose of making such arrangements for the determination of outstanding applications as it considers appropriate and those directions shall be complied with by the body to whom they are made; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) without prejudice to the generality of subparagraph (a), authorise another notified body, or approved body or national approved body to take over the functions of the body whose appointment has been terminated in respect of such cases as it may specify. | ||||||||||||||||||||||||||||||||||||||||||||

(10) A person aggrieved by a decision of the competent authority under this Regulation may, by notice in writing given to the Minister, not later than 14 days after the receipt by that person of notice of that decision, appeal the decision. | ||||||||||||||||||||||||||||||||||||||||||||

(11) The Minister, having considered any submissions made to him or her by an appellant, the competent authority or any other interested party, and, if applicable, the report of any inquiry held under paragraph (12) or of any assessor appointed under paragraph (13) in relation thereto, may uphold, vary or reverse the decision of the competent authority. | ||||||||||||||||||||||||||||||||||||||||||||

(12) The Minister may appoint an officer of the Minister to hold an inquiry in connection with an appeal under this Regulation and to make a report to him or her on the findings and result of that inquiry. | ||||||||||||||||||||||||||||||||||||||||||||

(13) The Minister may appoint an assessor to assist him or her and to make a report to him or her in relation to an appeal under this Regulation or to assist an officer of the Minister in relation to an inquiry being held by him or her under paragraph (12). | ||||||||||||||||||||||||||||||||||||||||||||

|

Conformity marking | 11. (1) Without prejudice to the requirements for the marking of receptacles and tanks laid down in the ADR Directive and RID Directive, receptacles and tanks satisfying the provisions of Regulations 4 and 6 shall have the conformity mark affixed to them in accordance with Schedule 2. | |||||||||||||||||||||||||||||||||||||||||||

(2) The conformity mark shall be visibly and immovably affixed and shall be accompanied by the identification number of the notified body which has performed the conformity assessment procedure on the receptacles and tanks. | ||||||||||||||||||||||||||||||||||||||||||||

(3) In the case of reassessment of conformity, the mark shall be accompanied by the identification number of the notified or approved body. | ||||||||||||||||||||||||||||||||||||||||||||

(4) Valves and other accessories manufactured on or after 1 July 2001 [check other dates for consistency] and having a direct safety function shall bear either the conformity mark or the “CE” mark and such marks need not be accompanied by the identification number of the notified body which carried out the conformity assessment on the valves and other accessories used for transport. | ||||||||||||||||||||||||||||||||||||||||||||

(5) Valves and accessories other than those referred to in paragraph (4) shall not be subject to any special marking requirements. | ||||||||||||||||||||||||||||||||||||||||||||

(6) Without prejudice to the requirements for the marking of receptacles and tanks laid down in the ADR Directive and the RID Directive, for the purposes of periodic inspections, all transportable pressure equipment referred to in Regulation 7 shall bear the identification number of the body which performed the periodic inspection of the equipment to indicate that it may continue to be used. | ||||||||||||||||||||||||||||||||||||||||||||

(7) With regard to gas cylinders covered by the separate Directives, when the first periodic inspection is carried out in accordance with these Regulations, the identification number referred to in this Regulation shall be preceded by the conformity mark. | ||||||||||||||||||||||||||||||||||||||||||||

(8) For both conformity assessment and reassessment and for periodic inspections, the identification number of the notified or approved body shall be visibly and immovably affixed under its responsibility either by the body itself or by the manufacturer, or his or her authorised representative established within the Community, or by the owner or his or her authorised representative established in the Community, or by the holder. | ||||||||||||||||||||||||||||||||||||||||||||

(9) The affixing of markings on transportable pressure equipment which are likely to mislead third parties with regard to the meaning or the graphics of the mark referred to in these Regulations is prohibited. | ||||||||||||||||||||||||||||||||||||||||||||

(10) Any other marking may be affixed to transportable pressure equipment provided that the visibility and legibility of the conformity marking is not thereby reduced. | ||||||||||||||||||||||||||||||||||||||||||||

|

Safeguard clause and undue marking | 12. (1) Where, in the opinion of the competent authority, transportable pressure equipment, when correctly maintained and used for its intended purpose, is liable to endanger the health or safety of persons and, where appropriate, domestic animals or property, during transport or use, notwithstanding the fact that the equipment bears a mark in accordance with Regulation 11[check cross reference], the competent authority may restrict or prohibit the placing on the market, transport or use of the equipment in question or have it withdrawn from the market or from circulation. | |||||||||||||||||||||||||||||||||||||||||||

(2) Without prejudice to paragraph (1), where the competent authority establishes that the conformity marking referred to in Regulation 11 has been affixed unduly, it may direct the owner or his or her authorised representative established in the State, or the holder, or the manufacturer or his or her authorised representative established in the State, to ensure that the relevant transportable pressure equipment conforms with Regulation 11, and the competent authority may restrict or prohibit the placing on the market, transport or use of the equipment in question or have it withdrawn from the market or from circulation. | ||||||||||||||||||||||||||||||||||||||||||||

(3) The competent authority shall forthwith notify the Commission of any decision under paragraphs (1) or (2). | ||||||||||||||||||||||||||||||||||||||||||||

|

Immunity of competent authorities | 13. No action or other proceeding shall lie or be maintainable against the competent authority of any officer of (including in the case of the competent authority, an inspector of the competent authority), servant of, or person engaged by, the competent authority for the recovery of damages in respect of any injury to persons or property alleged to have been caused or contributed to by a failure to perform or to comply with any of the functions provided for by these Regulations. | |||||||||||||||||||||||||||||||||||||||||||

|

Charges payable to the competent authority, notified body, approved body or national approved body | 14. (1) On the making of an application to a competent authority for the— | |||||||||||||||||||||||||||||||||||||||||||

(a) appointment of a notified body, or an approved body or national approved body; or | ||||||||||||||||||||||||||||||||||||||||||||

(b) amendment of an existing appointment of such a body; | ||||||||||||||||||||||||||||||||||||||||||||

there shall be payable by the applicant in connection with the performance by or on behalf of the competent authority of its functions in relation to that application the relevant fee in accordance with such scale of charges as may be specified by the Minister, as published from time to time in the Iris Oifigiúil. | ||||||||||||||||||||||||||||||||||||||||||||

(2) The fees referred to in respect of subparagraphs (a) or (b) of paragraph (1) are— | ||||||||||||||||||||||||||||||||||||||||||||

(a) a fee for processing an application, and | ||||||||||||||||||||||||||||||||||||||||||||

(b) such fee as is reasonable in relation to the actual work to be performed in respect of the determination of the suitability of the applicant for appointment or for the amendment of an existing appointment. | ||||||||||||||||||||||||||||||||||||||||||||

(3) A fee, which shall be reasonable in relation to the actual work performed, shall be payable by the relevant notified body, approved body or national approved body in respect of any inspection undertaken by or on behalf of the competent authority in accordance with Regulation 10(6). [check cross reference] | ||||||||||||||||||||||||||||||||||||||||||||

(4) Subject to paragraph (5), where an application has been made to a notified body, approved body or national approved body in accordance with these Regulations, the notified body, or approved body or national approved body, as the case may be, may charge such fees in connection with, or incidental to, carrying out its duties in relation to the procedures and tasks referred to in Regulation 10(4)(c) as it may determine. | ||||||||||||||||||||||||||||||||||||||||||||

(5) The fees referred to in paragraph (4) shall not exceed— | ||||||||||||||||||||||||||||||||||||||||||||

(a) the costs incurred or to be incurred by a notified body, approved body or national approved body in performing the relevant function; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) an amount on account of profit which is reasonable in the circumstances having regard to the— | ||||||||||||||||||||||||||||||||||||||||||||

(i) character and extent of the work done or to be done by that body on behalf of the applicant, and | ||||||||||||||||||||||||||||||||||||||||||||

(ii) commercial rate normally charged on account of profit for that work or similar work. | ||||||||||||||||||||||||||||||||||||||||||||

(6) In relation to paragraph (4) a notified body, approved body or national approved body may require the payment of fees or a reasonable estimate thereof in advance of carrying out the work requested by the applicant. | ||||||||||||||||||||||||||||||||||||||||||||

(7) A competent authority, a notified body, or an approved body or national approved body may recover, as a simple contract debt in any court of competent jurisdiction, from the person by whom it is payable, any amount due and owing to it under this Regulation. | ||||||||||||||||||||||||||||||||||||||||||||

|

Authorised officers. | 15. (1) The competent authority may appoint such and so many persons as it thinks fit, to be authorised officers for the purposes of these Regulations and any function conferred on the competent authority by these Regulations may be performed by an authorised officer. | |||||||||||||||||||||||||||||||||||||||||||

(2) A person appointed under paragraph (1) shall, on his or her appointment, be furnished by the competent authority, with a warrant of his or her appointment, and when exercising a power conferred by this Regulation shall, if requested by any person thereby affected, produce such warrant to that person for inspection. | ||||||||||||||||||||||||||||||||||||||||||||

(3) An authorised officer may, for the purposes of these Regulations— | ||||||||||||||||||||||||||||||||||||||||||||

(a) enter, inspect, examine and search at all times any premises at which he or she has reasonable grounds for believing that transportable pressure equipment is being manufactured, used or stored, or any premises that are part of an undertaking engaged in the manufacture of that transportable pressure equipment; | ||||||||||||||||||||||||||||||||||||||||||||

(b) take with him or her a member of the Garda Síochána if he or she has reasonable cause to apprehend any serious obstruction in the execution of his or her duty; | ||||||||||||||||||||||||||||||||||||||||||||

(c) take with him or her any other person authorised by the competent authority or equipment or materials required for any purpose for which the power of entry is being exercised; | ||||||||||||||||||||||||||||||||||||||||||||

(d) where he or she has reasonable cause to believe that at or in any premises an offence under these Regulations has been or is being committed, use reasonable force where necessary in order to enter the premises, provided he or she is so authorised by a warrant of a judge of the District Court (which such judge is hereby authorised to issue upon reasonable grounds being given on oath); | ||||||||||||||||||||||||||||||||||||||||||||

(e) at any premises referred to in subparagraph (a), inspect and take copies of, or extracts from, any books, records or other documents which he or she finds in the course of his or her inspection; | ||||||||||||||||||||||||||||||||||||||||||||

(f) carry out or have carried out such examinations, tests, inspections and checks of the premises, of any transportable pressure equipment or assemblies being manufactured or stored at the premises, or of any equipment, machinery or plant at the premises as he or she reasonably considers to be necessary for the purposes of his or her functions under these Regulations; | ||||||||||||||||||||||||||||||||||||||||||||

(g) require any person at the premises or the owner or person in charge of the premises and any person employed in connection therewith to give to him or her such information and to produce to him or her such books, documents and other records that are in that person’s power or procurement as he or she may reasonable require for the purposes of his or her functions under these Regulations; | ||||||||||||||||||||||||||||||||||||||||||||

(h) require any person whom he or she has reasonable cause to believe to be able to give information relevant to any examination under these Regulations, to answer either alone or in the presence of any other person, as he or she thinks fit, such questions with respect to matters under these Regulations as he or she thinks fit to ask and sign a declaration of the truth of the answers given, provided that no one shall be required to answer any question or to give any evidence tending to incriminate himself or herself; | ||||||||||||||||||||||||||||||||||||||||||||

(i) direct that any premises referred to in subparagraph (a) or part of such premises and anything therein shall be left undisturbed for so long as it is reasonably necessary for the purpose of any examination or inquiry under these Regulations; | ||||||||||||||||||||||||||||||||||||||||||||

(j) take possession of and remove from the premises for examination and checking by the competent authority or a notified body, approved body or national approved body in the State, transportable pressure equipment or any part thereof, and retain such transportable pressure equipment or part thereof for such time as he or she considers reasonable for the purposes of his or her functions under these Regulations; | ||||||||||||||||||||||||||||||||||||||||||||

(k) as regards any article or substance he or she finds at or in a premises to which subparagraph (a) applies, require the proprietor or any person he or she finds at the premises or any person who appears to him or her to be in possession of the article or substance, to supply without payment, for test, examination or analysis sufficient samples thereof; | ||||||||||||||||||||||||||||||||||||||||||||

(l) cause any article or substance found at or in any premises which appears to him or her to have caused or to be likely to cause danger to safety or health, to be dismantled or subjected to any process or test (but not so as to damage or destroy it unless this is in the circumstances necessary for the purposes of these Regulations) and where an authorised officer proposes to exercise the power conferred by this subparagraph in the case of an article or substance found at or in any premises, he or she shall, if so requested by a person who at the time is present at or in and has responsibilities in relation to that premises, cause anything which is to be done by virtue of that power to be done in the presence of that person; | ||||||||||||||||||||||||||||||||||||||||||||

(m) in relation to any article or substance found at a premises in accordance with subparagraph (l), take possession of it and detain it for so long as is necessary for all or any of the following purposes, namely— | ||||||||||||||||||||||||||||||||||||||||||||

(i) examine or arrange for the examination of it and do to it anything which he or she has power to do under subparagraph (1); | ||||||||||||||||||||||||||||||||||||||||||||

(ii) ensure that it is not tampered with before the examination of it is completed; | ||||||||||||||||||||||||||||||||||||||||||||

(iii) ensure that it is available for use as evidence in any proceedings; | ||||||||||||||||||||||||||||||||||||||||||||

(n) take any measurements or photographs or make any recordings which he or she considers necessary for the purposes of any inspection, or examination made by him or her under these Regulations; and | ||||||||||||||||||||||||||||||||||||||||||||

(o) require any person to afford him or her such facilities and assistance within his or her control or responsibilities as are reasonably necessary to enable him or her to exercise any of the powers conferred on him or her under these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||

|

Indemnification of authorised officers | 16. Where the competent authority is satisfied that an authorised officer appointed by it under these Regulations, or any other member of the staff of the authority, has discharged his or her duties in relation to the carrying out of functions under these Regulations in a bona fide manner, it shall indemnify the authorised officer, or such member of the staff of the competent authority, against all actions or claims howsoever arising in respect of the discharge by him or her of duties. | |||||||||||||||||||||||||||||||||||||||||||

|

Obtaining of information by the competent authority. | 17. (1) The competent authority may, for the purpose of obtaining information which it requires for the discharge of functions under these Regulations, by a notice in writing (in this Regulation referred to as “a notice requiring information”) served on any person, require such person to furnish to the competent authority within a period specified in the notice and in such form, if any, as may be specified in the notice, information about any matters specified in the notice. | |||||||||||||||||||||||||||||||||||||||||||

(2) The competent authority shall not serve a notice requiring information unless, having regard to all the circumstances of the particular case, the information is reasonably required in connection with the exercise of functions under these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||

(3) A person shall provide the information requested in a notice requiring information— | ||||||||||||||||||||||||||||||||||||||||||||

(a) where no appeal is taken against the notice — | ||||||||||||||||||||||||||||||||||||||||||||

(i) on the expiration of the period during which such an appeal may be taken, | ||||||||||||||||||||||||||||||||||||||||||||

(ii) within the period of time specified in the notice for the purpose of the furnishing of the information, or | ||||||||||||||||||||||||||||||||||||||||||||

(iii) on such subsequent day as the competent authority may agree in writing, | ||||||||||||||||||||||||||||||||||||||||||||

whichever is the later; | ||||||||||||||||||||||||||||||||||||||||||||

(b) where an appeal is taken and the notice is confirmed on appeal or the appeal is withdrawn— | ||||||||||||||||||||||||||||||||||||||||||||

(i) on the day following the day on which the notice is so confirmed or the appeal is withdrawn, | ||||||||||||||||||||||||||||||||||||||||||||

(ii) within the period of time specified in the notice for the purpose of the furnishing of the information, or | ||||||||||||||||||||||||||||||||||||||||||||

(iii) in case the operation of the notice has been suspended in accordance with paragraph (4)(b), on the expiration of the period that the judge of the District Court considered appropriate for the purpose of that subparagraph, | ||||||||||||||||||||||||||||||||||||||||||||

whichever is the later. | ||||||||||||||||||||||||||||||||||||||||||||

(4) (a) Where a person is aggrieved by a notice requiring information served on him or her, he or she may, within the period of 7 days beginning on the day on which the notice is so served, appeal to a judge of the District Court in the District Court District in which the notice is served in the prescribed manner against the notice and, in determining the appeal, the judge may— | ||||||||||||||||||||||||||||||||||||||||||||

(i) if he or she is satisfied that in the circumstances of the case it is reasonable to do so, confirm the notice, with or without modification; or | ||||||||||||||||||||||||||||||||||||||||||||

(ii) cancel the notice; | ||||||||||||||||||||||||||||||||||||||||||||

(b) where on the hearing of an appeal under subparagraph (a) a notice requiring information is confirmed, the judge by whom the appeal is heard, may on the application of the appellant, suspend the operation of the notice for such period as in the circumstances of the case he or she considers appropriate; | ||||||||||||||||||||||||||||||||||||||||||||

(c) the judge determining an appeal under subparagraph (a) may make such order as to the payment of costs in respect of the appeal as he or she considers appropriate. | ||||||||||||||||||||||||||||||||||||||||||||

(5) Where any opinion of the competent authority to which paragraph (2) relates purports to be contained in any document which— | ||||||||||||||||||||||||||||||||||||||||||||

(a) purports to have been made by or at the direction of the competent authority; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) is produced in evidence by an officer of the competent authority in any proceedings, | ||||||||||||||||||||||||||||||||||||||||||||

such document shall be admissible in evidence and shall be evidence of any such opinion in such proceedings without further proof. | ||||||||||||||||||||||||||||||||||||||||||||

|

Offences | 18. (1) A person who, in relation to the conformity mark or any document required for the purposes of these Regulations— | |||||||||||||||||||||||||||||||||||||||||||

(a) forges or counterfeits any such document or mark, | ||||||||||||||||||||||||||||||||||||||||||||

(b) gives or signs a document or makes a mark knowing it to be false in any material particular, | ||||||||||||||||||||||||||||||||||||||||||||

(c) knowingly utters or uses a document or mark so forged or counterfeited, or which is false as aforesaid, | ||||||||||||||||||||||||||||||||||||||||||||

(d) knowingly utters or uses as applying to any person a document or mark which does not so apply, | ||||||||||||||||||||||||||||||||||||||||||||

(e) knowingly connives at any such forging, counterfeiting, giving, signing, uttering or using, | ||||||||||||||||||||||||||||||||||||||||||||

(f) knowingly makes a false entry in any such document which is so required to be kept, served or sent, or | ||||||||||||||||||||||||||||||||||||||||||||

(g) knowingly uses any such false entry, | ||||||||||||||||||||||||||||||||||||||||||||

is guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||

(2) Any person who contravenes Regulation 11(9) is guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||

(3) A person who fails to comply with a direction given under Regulation 12(2) is guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||

(4) A person who— | ||||||||||||||||||||||||||||||||||||||||||||

(a) personates any person named in any document required for the purposes of these Regulations, | ||||||||||||||||||||||||||||||||||||||||||||

(b) falsely pretends to be an authorised officer, inspector or member of staff of the competent authority, notified body or approved body, or | ||||||||||||||||||||||||||||||||||||||||||||

(c) wilfully connives at any such personation or pretence, | ||||||||||||||||||||||||||||||||||||||||||||

is guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||

(5) A person who obstructs or interferes with an authorised officer in the course of exercising a power conferred on him or her by these Regulations or impedes the exercise by the officer of such power or fails or refuses to comply with a request made by, or to answer a question asked by, an authorised officer pursuant to these Regulations or in purported compliance with such request or in answer to such question gives information to an officer that he or she knows to be false or misleading in a material respect is guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||

(6) Where an offence under these Regulations is committed by a body corporate and is proved to have been so committed with the consent or connivance of or to be attributable to any neglect on the part of any person, being a director, manager, secretary or other officer of the body corporate, or a person who was purporting to act in any such capacity, that person, as well as the body corporate, is guilty of an offence and shall be liable to be proceeded against and punished as if he or she were guilty of the first-mentioned offence. | ||||||||||||||||||||||||||||||||||||||||||||

(7) In any proceedings for an offence for a contravention of any of the provisions of these Regulations it shall be a defence for the person charged to prove— | ||||||||||||||||||||||||||||||||||||||||||||

(a) that the commission of the offence was due to the act or default of another person not being one of his or her employees; and | ||||||||||||||||||||||||||||||||||||||||||||

(b) that he or she took all reasonable precautions and exercised all due diligence to avoid the commission of the offence. | ||||||||||||||||||||||||||||||||||||||||||||

|

Penalties | 19. A person guilty of an offence under these Regulations is liable on summary conviction to a fine not exceeding €3,000. | |||||||||||||||||||||||||||||||||||||||||||

|

Prosecution of offences | 20. A prosecution for an offence under these Regulations may be brought by the competent authority. | |||||||||||||||||||||||||||||||||||||||||||

|

Cost of prosecutions | 21. Where a person is convicted of an offence under these Regulations, the court shall, unless it is satisfied that there are special and substantial reasons for not so doing, order the person to pay to the competent authority the costs and expenses, measured by the court, incurred by the competent authority in relation to the investigation, detection and prosecution of the offence, including costs and expenses incurred in the taking of samples, the carrying out of tests, examinations and analyses and in respect of the remuneration and other expenses of employees or persons engaged by the competent authority. | |||||||||||||||||||||||||||||||||||||||||||

|

SCHEDULE 1 | ||||||||||||||||||||||||||||||||||||||||||||

| Regulation 2(1) | List of dangerous substances other than those referred to in the definition of “transportable pressure equipment” in Regulation 2(1) | |||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||

|

SCHEDULE 2 | ||||||||||||||||||||||||||||||||||||||||||||

| Regulation 4 and 5 | Conformity assessment procedures | |||||||||||||||||||||||||||||||||||||||||||

|

Module A — internal production control | ||||||||||||||||||||||||||||||||||||||||||||

1. This module describes the procedure whereby the manufacturer, or his or her authorised representative established within the Community who carries out the obligations laid down in paragraph 2, ensures and declares that transportable pressure equipment satisfies the relevant requirements of these Regulations. The manufacturer, or his or her authorised representative established within the Community, must affix the conformity marking to all such transportable pressure equipment and draw up a written declaration of conformity. | ||||||||||||||||||||||||||||||||||||||||||||

2. The manufacturer must draw up the technical documentation described in paragraph 3 and either the manufacturer or his or her authorised representative established within the Community must keep it at the disposal of the competent authority for inspection purposes for a period of 10 years after the last of the transportable pressure equipment has been manufactured. Where neither the manufacturer nor his or her authorised representative is established within the Community, the obligation to keep the technical documentation available is the responsibility of the person who places the transportable pressure equipment on the market. | ||||||||||||||||||||||||||||||||||||||||||||

3. The technical documentation must enable an assessment to be made of the conformity of the transportable pressure equipment with the relevant requirements of these Regulations. It must, as far as is relevant for such assessment, cover the design, manufacture and operation of the transportable pressure equipment and contain: | ||||||||||||||||||||||||||||||||||||||||||||

— a general description of the transportable pressure equipment, | ||||||||||||||||||||||||||||||||||||||||||||

— conceptual design and manufacturing drawings and diagrams of components, sub-assemblies, circuits, etc, | ||||||||||||||||||||||||||||||||||||||||||||

— descriptions and explanations necessary for an understanding of the said drawings and diagrams and the operation of the transportable pressure equipment, | ||||||||||||||||||||||||||||||||||||||||||||

— a description of the solutions adopted to meet the requirements of these Regulations, | ||||||||||||||||||||||||||||||||||||||||||||

— results of the design calculations, examinations carried out, etc, | ||||||||||||||||||||||||||||||||||||||||||||

— test reports. | ||||||||||||||||||||||||||||||||||||||||||||

4. The manufacturer, or his or her authorised representative established within the Community, must keep a copy of the declaration of conformity with the technical documentation. | ||||||||||||||||||||||||||||||||||||||||||||

5. The manufacturer must take all measures necessary to ensure that the manufacturing process requires the manufactured transportable pressure equipment to comply with the technical documentation referred to in paragraph 2 and with the relevant requirements of these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||

|

Module A1 — internal manufacturing checks with monitoring of the final assessment | ||||||||||||||||||||||||||||||||||||||||||||

In addition to the requirements of module A, the following applies. | ||||||||||||||||||||||||||||||||||||||||||||

Final assessment must be performed by the manufacturer and monitored by means of unexpected visits by a notified body chosen by the manufacturer. | ||||||||||||||||||||||||||||||||||||||||||||

During such visits, the notified body must: | ||||||||||||||||||||||||||||||||||||||||||||

— ensure that the manufacturer actually performs final assessment, | ||||||||||||||||||||||||||||||||||||||||||||

— take samples of the transportable pressure equipment at the manufacturing or storage premises in order to conduct checks. The notified body assesses the number of items of equipment to sample and whether it is necessary to perform, or have performed, all or part of the final assessment of the equipment samples. | ||||||||||||||||||||||||||||||||||||||||||||

Should one or more of the items of transportable pressure equipment not conform, the notified body must take appropriate measures. | ||||||||||||||||||||||||||||||||||||||||||||

On the responsibility of the notified body, the manufacturer must affix that body’s identification number to each item of transportable pressure equipment. | ||||||||||||||||||||||||||||||||||||||||||||

|

Module B — EC-type examination | ||||||||||||||||||||||||||||||||||||||||||||

1. This module describes the part of the procedure by which a notified body ascertains and attests that a representative example of the production envisaged meets the relevant requirements of these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||

2. The application for EC-type-examination must be lodged by the manufacturer or by his or her authorised representative established within the Community with a single notified body of his or her choice. | ||||||||||||||||||||||||||||||||||||||||||||

The application must include: | ||||||||||||||||||||||||||||||||||||||||||||

— the name and address of the manufacturer and, if the application is lodged by the authorised representative established within the Community, his or her name and address as well, | ||||||||||||||||||||||||||||||||||||||||||||

— a written declaration that the same application has not been lodged with any other notified body, | ||||||||||||||||||||||||||||||||||||||||||||

— the technical documentation described in paragraph 3. | ||||||||||||||||||||||||||||||||||||||||||||

The applicant must place at the disposal of the notified body a representative example of the production envisaged, hereinafter called “type”. The notified body may request further examples should the test programme so require. | ||||||||||||||||||||||||||||||||||||||||||||

A type may cover several versions of the transportable pressure equipment provided that the differences between the versions do not affect the level of safety. | ||||||||||||||||||||||||||||||||||||||||||||

3. The technical documentation must enable an assessment to be made of the conformity of the transportable pressure equipment with the relevant requirements of these Regulations. It must, as far as is relevant for such assessment, cover the design, manufacture and operation of the transportable pressure equipment and contain: | ||||||||||||||||||||||||||||||||||||||||||||

— a general description of the type, | ||||||||||||||||||||||||||||||||||||||||||||

— conceptual design and manufacturing drawings and diagrams of components, sub-assemblies, circuits, etc, | ||||||||||||||||||||||||||||||||||||||||||||

— descriptions and explanations necessary for an understanding of the said drawings and diagrams and the operation of the transportable pressure equipment, | ||||||||||||||||||||||||||||||||||||||||||||

— a description of the solutions adopted to meet the essential requirements of these Regulations, | ||||||||||||||||||||||||||||||||||||||||||||

— test reports, | ||||||||||||||||||||||||||||||||||||||||||||

— results of the design calculations made, examinations carried out, etc, | ||||||||||||||||||||||||||||||||||||||||||||

— information concerning the tests provided for in manufacture, | ||||||||||||||||||||||||||||||||||||||||||||

— information concerning the qualifications or approvals. | ||||||||||||||||||||||||||||||||||||||||||||

4. The notified body must: | ||||||||||||||||||||||||||||||||||||||||||||

4.1 examine the technical documentation, verify that the type has been manufactured in conformity with it and identify the components designed in accordance with the relevant requirements of these Regulations and in particular: | ||||||||||||||||||||||||||||||||||||||||||||

— examine the technical documentation with respect to the design and the manufacturing procedures, | ||||||||||||||||||||||||||||||||||||||||||||

— assess the materials used where these are not in conformity with the relevant provisions of these Regulations and check the certificate issued by the materials manufacturer, | ||||||||||||||||||||||||||||||||||||||||||||

— approve the procedures for the permanent joining of pressure equipment parts or check that they have been previously approved, | ||||||||||||||||||||||||||||||||||||||||||||

— verify that the staff undertaking the permanent joining of pressure equipment parts and the non-destructive tests are qualified or approved, | ||||||||||||||||||||||||||||||||||||||||||||

4.2 perform or have performed the appropriate examinations and necessary tests to establish whether the solutions adopted by the manufacturer meet the relevant requirements of these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||

4.3 perform or have performed the appropriate examinations and necessary tests to establish whether the relevant provisions of these Regulations have been applied. | ||||||||||||||||||||||||||||||||||||||||||||

4.4 agree with the applicant the location where the examinations and necessary tests are to be carried out. | ||||||||||||||||||||||||||||||||||||||||||||

5. Where the type satisfies the relevant provisions of these Regulations, the notified body must issue an EC type-examination certificate to the applicant. The certificate, which should be valid for 10 years and be renewable, must contain the name and address of the manufacturer, the conclusions of the examination and the necessary data for identification of the approved type. | ||||||||||||||||||||||||||||||||||||||||||||

A list of the relevant parts of the technical documentation must be annexed to the certificate and a copy kept by the notified body. | ||||||||||||||||||||||||||||||||||||||||||||

If the notified body refuses to issue an EC type-examination certificate to the manufacturer or to his or her authorised representative established within the Community, that body must provide detailed reasons for such refusal. Provision must be made for an appeals procedure. | ||||||||||||||||||||||||||||||||||||||||||||

6. The applicant must inform the notified body that holds the technical documentation concerning the EC type-examination certificate of all modifications to the approved transportable pressure equipment; these are subject to additional approval where they may affect conformity with the relevant requirements of these Regulations or the prescribed conditions for use of the equipment. This additional approval must be given in the form of an addition to the original EC type-examination certificate. | ||||||||||||||||||||||||||||||||||||||||||||

7. Each notified body must communicate to the Member States the relevant information concerning EC type-examination certificates which it has withdrawn, and, on request, those it has issued. | ||||||||||||||||||||||||||||||||||||||||||||

Each notified body must also communicate to the other notified bodies the relevant information concerning the EC type-examination certificates it has withdrawn or refused. | ||||||||||||||||||||||||||||||||||||||||||||

8. The other notified bodies may receive copies of the EC type-examination certificates and/or their additions. The annexes to the certificates must be held at the disposal of the other notified bodies. | ||||||||||||||||||||||||||||||||||||||||||||

9. The manufacturer, or his or her authorised representative established within the Community, must keep with the technical documentation copies of EC type-examination certificates and their additions for a period of 10 years after the last of the transportable pressure equipment has been manufactured. | ||||||||||||||||||||||||||||||||||||||||||||

Where neither the manufacturer nor his or her authorised representative is established within the Community, the obligation to keep the technical documentation available is the responsibility of the person who places the product on the market. | ||||||||||||||||||||||||||||||||||||||||||||

|

Module B1 — EC design examination | ||||||||||||||||||||||||||||||||||||||||||||

1. This module describes the part of the procedure whereby a notified body ascertains and attests that the design of an item of transportable pressure equipment meets the relevant provisions of these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||

2. The manufacturer, or his or her authorised representative established within the Community, must lodge an application for EC design examination with a single notified body which must include: | ||||||||||||||||||||||||||||||||||||||||||||

— the name, and address of the manufacturer and, if the application is lodged by the authorised representative established within the Community, his or her name and address as well, | ||||||||||||||||||||||||||||||||||||||||||||

— a written declaration that the same application has not been lodged with any other notified body, | ||||||||||||||||||||||||||||||||||||||||||||

— the technical documentation described in paragraph 3, | ||||||||||||||||||||||||||||||||||||||||||||

and may cover several versions of the transportable pressure equipment provided that the differences between the versions do not affect the level of safety. | ||||||||||||||||||||||||||||||||||||||||||||

3. The technical documentation must enable an assessment to be made of the conformity of the transportable pressure equipment with the relevant requirements of these Regulations. It must, as far as is relevant for such assessment, cover the design, manufacture and operation of the transportable pressure equipment and contain: | ||||||||||||||||||||||||||||||||||||||||||||

— a general description of the equipment in question, | ||||||||||||||||||||||||||||||||||||||||||||

— conceptual design and manufacturing drawings and diagrams of components, sub-assemblies, circuits, etc, | ||||||||||||||||||||||||||||||||||||||||||||

— descriptions and explanations necessary for an understanding of the said drawings and diagrams and the operation of the equipment, | ||||||||||||||||||||||||||||||||||||||||||||

— a description of the solutions adopted to meet the relevant requirements of these Regulations, | ||||||||||||||||||||||||||||||||||||||||||||

— the necessary supporting evidence for the adequacy of the design solution; this supporting evidence must include the results of tests carried out by the appropriate laboratory of the manufacturer or on his or her behalf, | ||||||||||||||||||||||||||||||||||||||||||||

— results of the design calculations made, examinations carried out, etc, | ||||||||||||||||||||||||||||||||||||||||||||

— information regarding qualifications or approvals. | ||||||||||||||||||||||||||||||||||||||||||||

4. The notified body must: | ||||||||||||||||||||||||||||||||||||||||||||

4.1 examine the technical documentation and identify the components which have been designed in accordance with the relevant provisions of these Regulations and in particular must: | ||||||||||||||||||||||||||||||||||||||||||||

— assess the materials used where these are not in conformity with the relevant provisions of these Regulations, | ||||||||||||||||||||||||||||||||||||||||||||

— approve the procedures for the permanent joining of pressure equipment parts or check that they have been previously approved, | ||||||||||||||||||||||||||||||||||||||||||||

— verify that the staff undertaking the permanent joining of pressure equipment parts and the non-destructive tests are qualified or approved; | ||||||||||||||||||||||||||||||||||||||||||||

4.2 perform the necessary examinations to establish whether the solutions adopted by the manufacturer meet the relevant requirements of these Regulations; | ||||||||||||||||||||||||||||||||||||||||||||

4.3 perform the necessary examinations to establish whether the relevant provisions of these Regulations have actually been applied. | ||||||||||||||||||||||||||||||||||||||||||||

5. Where the design meets the relevant provisions of these Regulations which apply to it, the notified body must issue an EC design-examination certificate to the applicant. The certificate must contain the name and address of the applicant, the conclusions of the examination, conditions for its validity and the necessary data for identification of the approved design. | ||||||||||||||||||||||||||||||||||||||||||||

A list of the relevant parts of the technical documentation must be annexed to the certificate and a copy kept by the notified body. | ||||||||||||||||||||||||||||||||||||||||||||

If the notified body refuses to issue an EC design-examination certificate to the manufacturer or to his or her authorised representative established within the Community, that body must provide detailed reasons for such refusal. Provision must be made for an appeals procedure. | ||||||||||||||||||||||||||||||||||||||||||||

6. The applicant must inform the notified body that holds the technical documentation concerning the EC design-examination certificate of all modifications to the approved design; these are subject to additional approval where they may affect conformity with the relevant requirements of the Regulations or the prescribed conditions for use of the equipment. This additional approval must be given in the form of an addition to the original EC design-examination certificate. | ||||||||||||||||||||||||||||||||||||||||||||

7. Each notified body must communicate to the Member States the relevant information concerning EC design-examination certificates which it has withdrawn, and, on request, those it has issued. | ||||||||||||||||||||||||||||||||||||||||||||

Each notified body must also communicate to the other notified bodies the relevant information concerning the EC design-examination certificates it has withdrawn or refused. | ||||||||||||||||||||||||||||||||||||||||||||

8. The other notified bodies may on request obtain the relevant information concerning: | ||||||||||||||||||||||||||||||||||||||||||||

— the EC design-examination certificates and additions granted, | ||||||||||||||||||||||||||||||||||||||||||||

— the EC design-examination certificates and additions withdrawn. | ||||||||||||||||||||||||||||||||||||||||||||

9. The manufacturer, or his or her authorised representative established within the Community, must keep with the technical documentation referred to in paragraph 3, copies of EC design-examination certificates and their additions for a period of 10 years after the last of the transportable pressure equipment has been manufactured. | ||||||||||||||||||||||||||||||||||||||||||||

— Where neither the manufacturer nor his or her authorised representative is established within the Community, the obligation to keep the technical documentation available is the responsibility of the person who places the product on the market. | ||||||||||||||||||||||||||||||||||||||||||||

|

Module C1 — conformity to type | ||||||||||||||||||||||||||||||||||||||||||||

1. This module describes that part of the procedure whereby the manufacturer, or his or her authorised representative established within the Community, ensures and declares that transportable pressure equipment is in conformity with the type as described in the EC type-examination certificate and satisfy the relevant requirements of these Regulations. The manufacturer, or his or her authorised representative established within the Community, must affix the conformity marking to all such transportable pressure equipment and draw up a written declaration of conformity. | ||||||||||||||||||||||||||||||||||||||||||||

2. The manufacturer must take all measures necessary to ensure that the manufacturing process requires the manufactured transportable pressure equipment to comply with the type as described in the EC type-examination certificate and with the relevant requirements of these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||

3. The manufacturer, or his or her authorised representative established within the Community, must keep a copy of the declaration of conformity for a period of 10 years after the last of the transportable pressure equipment has been manufactured. | ||||||||||||||||||||||||||||||||||||||||||||

Where neither the manufacturer nor his or her authorised representative is established within the Community, the obligation to keep the technical documentation available is the responsibility of the person who places the transportable pressure equipment on the market. | ||||||||||||||||||||||||||||||||||||||||||||

4. Final assessment must be subject to monitoring in the form of unexpected visits by a notified body chosen by the manufacturer. | ||||||||||||||||||||||||||||||||||||||||||||