S.I. No. 98/1967 - Merchant Shipping (Passenger Ship Construction) Rules, 1967.

S.I. No. 98 of 1967. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MERCHANT SHIPPING (PASSENGER SHIP CONSTRUCTION) RULES, 1967. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ARRANGEMENT OF RULES. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART I. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GENERAL. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rule | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2. Interpretation, application and exemption of certain ships on limited service. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART II. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

WATERTIGHT SUBDIVISION. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART II(A). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SHIPS NOT REQUIRED TO COMPLY WITH PART II | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART III. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BILGE PUMPING ARRANGEMENTS. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rule | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

27. Number and type of bilge pumps : Ships of Classes I and II. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

28. Number and type of bilge pumps : Ships of Classes II(A) and III. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

29. Number and type of bilge pumps, means for bailing : Ships of Classes IV to VI inclusive. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART IV. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ELECTRICAL EQUIPMENT AND INSTALLATIONS. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

39. Main generating sets : Ships of Classes I to III inclusive. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

40. Emergency source of electric power : Ships of Classes I, II and II(A). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

41. Emergency source of electric power : Ships of Class III. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART V. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FIRE PROTECTION: SHIPS OF CLASSES I, II AND II(A). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

54. Restriction of combustible material, etc : Methods I and III. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rule | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

55. Automatic fire alarm and fire detection systems : Methods I and III. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

56. Automatic sprinkler, fire alarm and fire detection systems : Method II. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

58. Separation of accommodation spaces from other enclosed spaces. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

59. Protection of lifts and vertical trunks for light and air. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART V(A) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FIRE PROTECTION : SHIPS OF CLASSES I, II AND II(A). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

65. Passenger ships carrying not more than 36 passengers to comply with certain Rules. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART V(B). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FIRE PROTECTION : SHIPS OF CLASSES III TO VI INCLUSIVE. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART VI. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BOILERS AND MACHINERY. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

81. Oil fuel installations : Cooking ranges and other heating appliances. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rule | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART VII. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MISCELLANEOUS. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FIRST SCHEDULE | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Areas of Smooth Waters and Partially Smooth Waters. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SECOND SCHEDULE. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Calculation of Maximum Length of Watertight Compartments. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

THIRD SCHEDULE. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stability in damaged condition. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FOURTH SCHEDULE. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

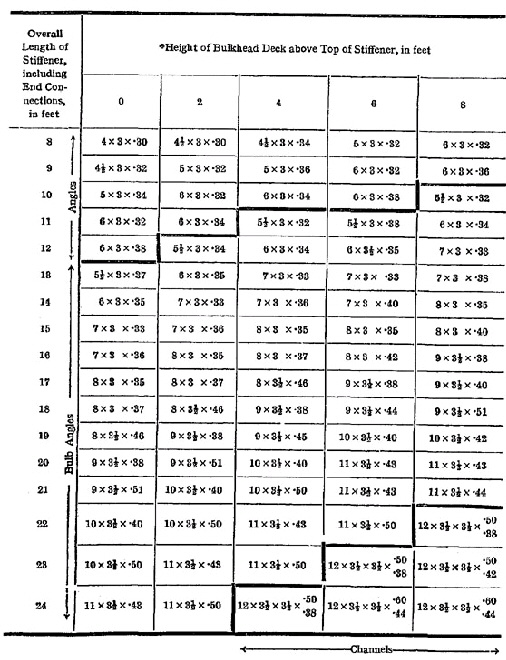

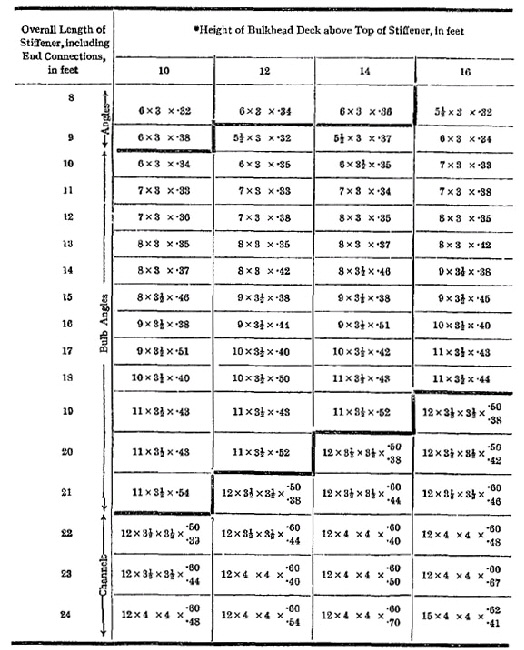

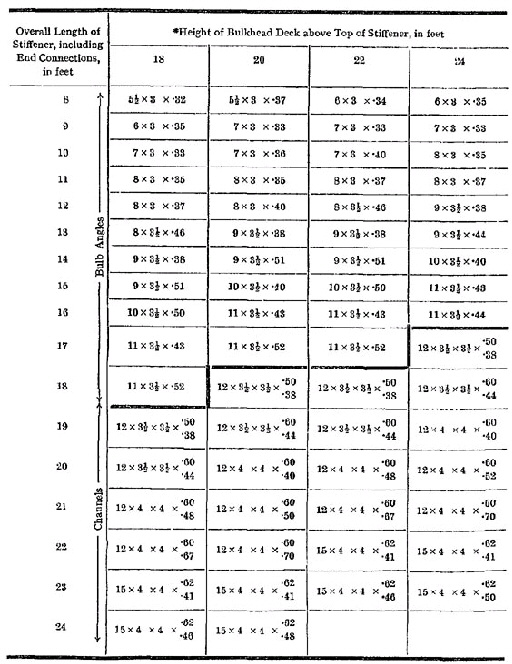

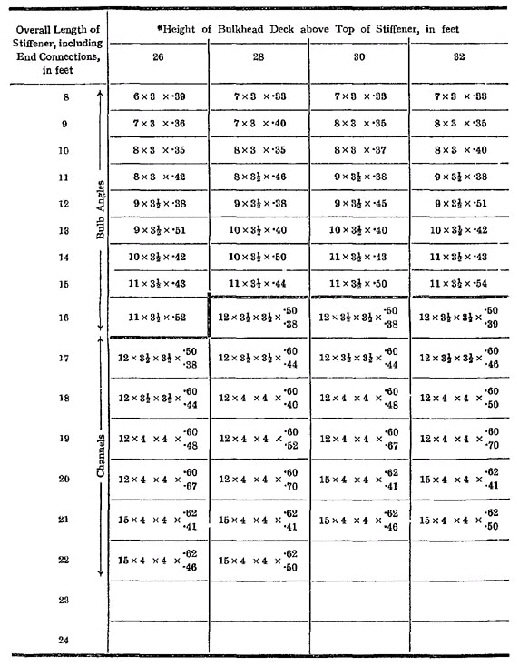

Construction of Watertight Bulkheads, etc. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FIFTH SCHEDULE. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Automatic Sprinkler, Fire Alarm, and Fire Detection system. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

S.I. No. 98 of 1967. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MERCHANT SHIPPING (PASSENGER SHIP CONSTRUCTION) RULES, 1967. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

I, ERSKINE H. CHILDERS, Minister for Transport and Power, in exercise of the powers conferred on me by section 10 of the Merchant Shipping (Safety Convention) Act, 1952 (No. 29 of 1952), as amended by section 9 of the Merchant Shipping Act, 1966 (No. 20 of 1966) and the Transport, Fuel and Power (Transfer of Departmental Administration and Ministerial Functions) Order, 1959 ( S.I. No. 125 of 1959 ), hereby make the following rules : | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

PART I. GENERAL. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 Short title, commencement and revocation. | 1.—(1) These Rules may be cited as the Merchant Shipping (Passenger Ship Construction) Rules, 1967. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) These Rules shall come into operation on the 14th day of May, 1967. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The Merchant Shipping (Construction) Rules, 1953 ( S.I. No. 339 of 1953 ), are hereby revoked. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 Interpretation, application and exemption of certain ships on limited service. | 2.—(1) In these Rules— | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

" 'A' class division " means a bulkhead or part of a deck, in either case complying with such of the requirements of Rule 50 as are expressed to apply to "A" class divisions ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"accommodation space" includes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) passenger spaces ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) crew space ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) offices ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(d) pantries ; and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(e) space similar to any of the foregoing, not being service spaces or open spaces on deck ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"auxiliary stairway" for the purpose of Rule 57(2) means a stairway of steel or other suitable material, which is not required by Rule 91 to form part of a means of escape and which serves only two decks ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

" 'B' class division" means a bulkhead complying with such of the requirements of Rule 50 as are expressed to apply to "B" class divisions ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"breadth of the ship" means the greatest moulded breadth at or below the ship's deepest subdivision load water line ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"bulkhead deck" means the uppermost deck up to which transverse watertight bulkheads are carried ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"cargo space" in Part V means space appropriated for cargo, other than mail and bullion, and trunks leading to such spaces ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"control station" includes :— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) a radiotelegraph room ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) any other enclosed space which houses | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) a compass, direction-finder, radar equipment, a steering wheel or other similar equipment used in navigation ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) a central indicator connected with a system for the detection of fire or smoke ; or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(iii) an emergency generator ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"crew space" means crew accommodation within the meaning of the Merchant Shipping (Crew Accommodation on Board Ship) Regulations, 1951 ( S.I. No. 95 of 1951 ) ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

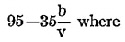

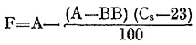

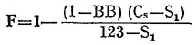

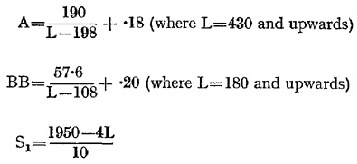

"criterion numeral" in relation to any ship means the criterion numeral of the ship determined in accordance with such of the provisions of the Second Schedule to these Rules as apply to that ship ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"draught" means the vertical distance from the moulded base line amidships to a subdivision load water line ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"equivalent material" where the words are used in the expression "steel or other equivalent material" means any material which, by itself or due to insulation provided, has structural and integrity properties equivalent to steel at the end of an appropriate fire test ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"factor of subdivision" in relation to any ship or portion thereof means the factor of subdivision determined in accordance with such of the provisions of the Second Schedule to these Rules as apply to that ship or portion as the case may be ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"floodable length" in relation to any portion of a ship at any draught means the maximum length of that portion having its centre at a given point in the ship which, at that draught and under such of the assumptions of permeability set forth in the Second Schedule to these Rules as are applicable in the circumstances, can be flooded without submerging any part of the ship's margin line when the ship has no list ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"incombustible material" means material which when heated to a temperature of 750°C. (1382°F.) neither burns nor gives off inflammable vapours in sufficient quantity to ignite at a pilot flame nor raises the temperature of the test furnace 50°C. (90°F.) or more above 750°C. (1382°F.) when tested in accordance with a specification approved by the Minister and "combustible material" shall be construed accordingly ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"independent power pump" means a pump operated by power otherwise than from the ship's main engines ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"length" in relation to a ship means the length of a ship measured between perpendiculars taken at the extremities of the deepest subdivision load water line ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"machinery space" in every Part, other than Parts V, V(A) and V(B), means any space extending from the moulded base line of the ship to the margin line and between the extreme transverse watertight bulkheads bounding the spaces containing the main and auxiliary propelling machinery, boilers serving the needs of propulsion, when installed, and the permanent coal bunkers, if any ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"machinery space" in Parts V, V(A) and V(B) means any space used for propelling, auxiliary or refrigerating machinery, boilers, pumps, engineers' workshops, generators, ventilation or air conditioning machinery, oil filling stations and similar spaces and trunkways to such spaces ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"main circulating pump" means the pump installed for circulating water through the main condenser ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"main vertical zones" means the main vertical zones into which the hull, superstructure and deck houses of a ship are divided in accordance with Rule 49(1) ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"margin line" means a line drawn at least 3 inches below the upper surface of the bulkhead deck at the side of a ship and assumed for the purpose of determining the floodable length of the ship ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"maximum service speed" means the greatest speed which the ship is designed to maintain at sea at her deepest seagoing draught ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"mile" means a nautical mile of 6080 feet ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"the Minister" means the Minister for Transport and Power ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"navigable speed" means the minimum speed at which the ship can be effectively steered in the ahead direction ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"oil fuel unit" means the equipment used for the preparation of oil fuel for delivery to the oil burners of an oil-fired boiler and includes the oil pressure pumps, filters and heaters ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"passenger space" means space provided for the use of passengers; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"passenger steamer" means a steamer carrying more than 12 passengers ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"permeability" in relation to a space means the percentage of that space below the ship's margin line which, on the assumption that it is in use for the purpose for which it is appropriated, can be occupied by water ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"permissible length" of a compartment having its centre at any point in the length of the ship means the product of the floodable length at that point and the factor of subdivision of the ship ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"public rooms" includes halls, dining rooms, bars, smoke rooms, lounges, recreation rooms, nurseries and libraries ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"radiotelegraph room" has the same meaning as in the Merchant Shipping (Radio) Rules, 1967 ( S.I. No. 103 of 1967 ) ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"service space" includes galleys, main pantries, laundries, store rooms, paint rooms, baggage rooms, mail rooms, bullion rooms, carpenters' and plumbers' workshops and trunkways leading to such spaces ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"settling tank" means an oil storage tank having a heating surface of not less than 2 square feet per ton of oil capacity ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"standard fire test" means a test in which specimens of the relevant bulkheads or decks, having a surface area of not less than 50 square feet and a height of 8 feet, resembling as closely as possible the intended construction and including where appropriate at least one joint, are exposed in a test furnace to a series of time temperature relationships, approximately as follows :— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

At the end of the first 5 minutes 538°C. (1000°F.) ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

At the end of the first 10 minutes 704°C. (1300°F.) ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

At the end of the first 30 minutes 843°C. (1550°F.) ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

At the end of the first 60 minutes 927°C. (1700°F.) ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"steamer" includes a ship propelled by electricity or other mechanical power ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"steering gear power unit" means | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) in the case of electric steering gear, the electric motor and its associated electrical equipment ; or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) in the case of electro-hydraulic steering gear, the electric motor, its associated electrical equipment and connected pump ; or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) in the case of steam-hydraulic or pneumatic-hydraulic steering gear, the driving engine and connected pump ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"subdivision load line" has the same meaning as in Section 34 of the Merchant Shipping (Safety Convention) Act, 1952 (No. 29 of 1952) ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"subdivision load water line" means the water line assumed in determining the subdivision of the ship in accordance with these Rules ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"suitable" in relation to material means approved by the Minister as suitable for the purpose for which it is used ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"surface spread of flame" for the purpose of Part V, means the surface spread of flame as defined in a specification approved by the Minister; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"tons" means gross tons ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"voyage" includes an excursion. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"watertight" in relation to a structure means capable of preventing the passage of water through the structure in any direction under a head of water up to the ship's margin line ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"weathertight" in relation to a structure means capable of preventing the passage of sea water through the structure in ordinary sea conditions. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) These Rules apply to passenger steamers registered in the State, provided that the Minister may exempt any ship the keel of which was laid before the date on which these Rules come into operation, not being a ship converted on or after that date for service as a passenger steamer, from the requirements of these Rules to the extent that he is satisfied that compliance therewith is unreasonable or impracticable in the circumstances. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The Minister may exempt any ship of Class II or II(A) which does not proceed more than 20 miles from the nearest land from the requirements of these Rules to the extent that he is satisfied that compliance therewith is unreasonable or impracticable by reason of the sheltered nature and conditions of the intended services of the ship. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3 Classification of ship. | 3.—(1) For the purposes of these Rules passenger steamers registered in the State shall be arranged in the following classes :— | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) Class I. Ships engaged on voyages (not being short international voyages) any of which are long international voyages, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Class II. Ships engaged on voyages (not being long international voyages) any of which are short international voyages, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) Class II(A). Ships engaged on voyages of any kind other than international voyages, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(d) Class III. Ships engaged only on voyages in the course of which they are at no time more than 70 miles by sea from their point of departure and not more than 18 miles from the coast of the State, and which are at sea only in fine weather and during restricted periods, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(e) Class IV. Ships engaged only on voyages in partially smooth waters, or voyages in smooth and partially smooth waters, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(f) Class V. Ships engaged only on voyages in smooth waters, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(g) Class VI. Ships engaged only on voyages with not more than 250 passengers on board, to sea, or in smooth or in partially smooth waters, in all cases in fine weather and during restricted periods, in the course of which the ships are at no time more than 15 miles, exclusive of any smooth waters, from their point of departure nor more than 3 miles from land. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) In this Rule the following expressions have the following meanings respectively :— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"long international voyage" means an international voyage which is not a short international voyage within the meaning of the Merchant Shipping (Safety Convention) Act, 1952 ( S.I. No. 29 of 1952 ) ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"partially smooth waters" means, as respects any period, weather or ship specified in the First Schedule to these Rules, the waters of any of the areas specified in the third column of that Schedule in relation to that period, weather or ship ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"restricted period" means a period falling wholly within either of the following periods :— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) between the 1st day of April and the 31st day of October in any year, both dates inclusive ; or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) between one hour before sunrise and one hour after sunset in the case of ships fitted with navigation lights conforming with the requirements of the Collision Regulations (Ships and Seaplanes on the Water) Order, 1965 ( S.I. No. 185 of 1965 ), and between sunrise and sunset in the case of any other ships ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"sea" does not include any partially smooth waters ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

"smooth waters" means any waters not being the sea or partially smooth waters, and in particular means waters of any of the areas specified in the second column of the First Schedule to these Rules. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 Structural strength. | 4. The structural strength of every ship to which these Rules apply shall be sufficient for the service for which the ship is intended. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

PART II WATERTIGHT SUBDIVISION | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

5 Application of Part II. | 5. This Part applies to every ship to which these Rules apply, not being an open or partially decked ship of Class V or a ship of Class VI carrying less than 101 passengers. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

6 Watertight subdivision. | 6. Every ship to which this Part applies shall be subdivided by bulkheads, which shall be watertight up to the bulkhead deck, into compartments the maximum length of which shall be calculated in accordance with such of the provisions of the Second Schedule to these Rules as apply to that ship. Every other portion of the internal structure which affects the efficiency of the subdivision of the ship shall be watertight, and shall be of a design which will maintain the integrity of the subdivision. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

7 Peak and machinery space bulkheads, shaft tunnels. etc. | 7.—(1) Every ship to which this Part applies shall be provided with a collision bulkhead which shall be watertight up to the bulkhead deck and shall be fitted at a distance from the ship's forward perpendicular of not less than 5 per cent. of the length of the ship and not more than 10 feet plus 5 per cent. of such length. If the ship has a forward superstructure, the collision bulkhead shall be extended weathertight to the deck next above the bulkhead deck. The extension shall not be required to be fitted directly over the bulkhead below, provided that it is at least 5 per cent. of the length of the ship from the forward perpendicular and the part of the bulkhead deck which forms the step is made effectively weathertight. The plating and stiffeners of such extension shall be constructed in accordance with the provisions of the Fourth Schedule to these Rules as if the extension formed part of a bulkhead immediately below the bulkhead deck. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Every ship to which this Part applies shall be provided with a watertight afterpeak bulkhead and with watertight bulkheads dividing the space appropriated to the main and auxiliary propelling machinery, boilers, if any, and the permanent coal bunkers, if any, from other spaces. Such bulkheads shall be watertight up to the bulkhead deck, provided that the afterpeak bulkhead may be stopped below the bulkhead deck if the safety of the ship is not thereby impaired. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The stern gland of every ship to which this Part applies shall be situated in a watertight shaft tunnel or other watertight space separate from the stern tube compartment and of such a volume that if the tunnel or space is flooded the margin line will not be submerged. The stern tube shall be enclosed in a watertight compartment, the volume of which shall be the smallest compatible with the proper design of the ship. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

8 Double bottoms. | 8.—(1) Subject to the provisions of this Rule every ship of Classes I, II and II(A) shall be fitted with a watertight double bottom which shall be at least of the following extent :— | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) in ships of 165 feet but of less than 200 feet in length—from the machinery space to the collision bulkhead or as near to that bulkhead as is practicable ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) in ships of 200 feet but of less than 249 feet in length—from the collision bulkhead to the afterpeak bulkhead or as near to those bulkheads as is practicable, but not necessarily in the machinery space ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) in ships of 249 feet in length or over—from the collision bulkhead to the afterpeak bulkhead or as near to those bulkheads as is practicable. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

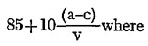

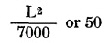

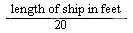

(2) In case a double bottom is required by this Rule to be fitted in a ship, its moulded depth in inches measured at the centre line shall be not less than 16 inches plus | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Wells constructed in the double bottom for the purpose of drainage shall not be larger nor extend downwards more than is necessary for such purpose. The depth of the well shall in no case be more than the depth of the double bottom at the centre line, less 18 inches, nor shall the well extend below the horizontal plane referred to in paragraph (2): Provided that a well extending to the outer bottom may be constructed at the after end of a shaft tunnel. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Wells for purposes other than drainage shall not be constructed in the double bottom. The Minister may exempt any ship from the requirements of this paragraph in respect of any well which he is satisfied will not diminish the protection given by the double bottom. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Nothing in this Rule shall require a double bottom to be fitted in way of watertight compartments of moderate size used exclusively for the carriage of liquids, if the safety of the ship will not be impaired in the event of bottom or side damage by reason of the absence of a double bottom in that position. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) The Minister may exempt any ship of Class II or II (A) from the requirements of a double bottom in any portion of the ship which is subdivided by application of a factor of subdivision not exceeding ·5, if he is satisfied that the fitting of a double bottom in that portion of the ship would not be compatible with the design and proper working of the ship. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

9 Stability in damaged condition. | 9.—(1) (a) Every ship to which this Part applies shall be so constructed as to provide sufficient intact stability in all service conditionsto enable the ship to withstand the final flooding of any one of the main compartments into which the ship is subdivided in accordance with the provisions of Rule 6. If two of the main compartments, being adjacent to each other, are separated by a bulkhead which is stepped under the conditions of paragraph 6 (3) (a) of the Second Schedule to these Rules, the intact stability shall be adequate to withstand the final flooding of those two adjacent main compartments. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Where in any such ship the factor of subdivision required under paragraph 4 or paragraph 9 of the Second Schedule to these Rules is ·50 or less but more than ·33 intact stability shall be adequate to withstand the final flooding of any two adjacent main compartments. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) Where in any such ship the factor of subdivision required under paragraph 4 of the Second Schedule to these Rules is ·33 or less the intact stability shall be adequate to withstand the final flooding of any three adjacent main compartments. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) For the purposes of this Rule the sufficiency of the intact stability of every such ship shall be determined in accordance with the provisions of the Third Schedule to these Rules. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) (a) Every ship to which this Part applies shall be so constructed as to keep unsymmetrical flooding when the ship is in a damaged condition at the minimum consistent with efficient arrangements. If cross-flooding fittings are provided in any such ship the fittings shall, where practicable, be self-acting but in any case where controls to cross-flooding fittings are provided, they shall be capable of being operated from an accessible position above the bulkhead deck. Such fittings together with their controls as well as the maximum heel before equalisation shall be such as will not endanger the safety of the ship. The cross-flooding fittings shall be capable of reducing the heel within 15 minutes, sufficiently to meet the requirements of sub-paragraphs (b) and (c) of paragraph 3 of the Third Schedule to these Rules. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) In case the margin line becomes submerged during the flooding assumed for the purposes of the calculation referred to in the Third Schedule to these Rules the construction of the ship shall be such as will enable the master of the ship to ensure— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) that the maximum angle of heel during any stage of such flooding will not be such as will endanger the safety of the ship, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) that the margin line will not be submerged in the final stage of flooding. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) (a) There shall be provided in every ship to which this Part applies a document for the use of the master of the ship containing information as to the use of any cross-flooding fittings provided in the ship. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) There shall be provided in every ship of Classes I, II and II(A) a document for the use of the master of the ship containing the following additional information :— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) information necessary for the maintenance of sufficient intact stability under service conditions to enable the ship to withstand damage to the extent referred to in the Third Schedule to these Rules ; and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) information as to the conditions of stability on which the calculations of heel have been based, together with a warning that excessive heeling might result should the ship sustain damage when in a less favourable condition. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 Ballasting. | 10. In case ballasting with water is necessary in any ship to which this Part applies, the water ballast shall not in general be carried in tanks intended for oil fuel. In ships in which it is not practicable to avoid putting water in oil fuel tanks, oily-water separator equipment to the satisfaction of the Minister shall be fitted, or an alternative means acceptable to the Minister shall be provided for disposing of the oily-water ballast. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

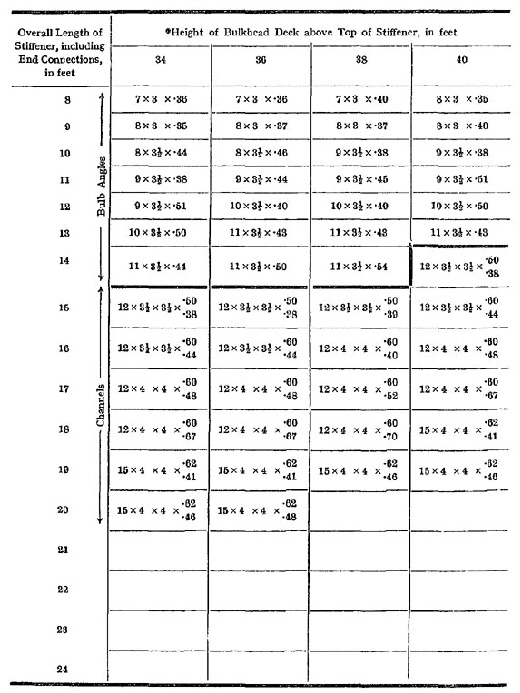

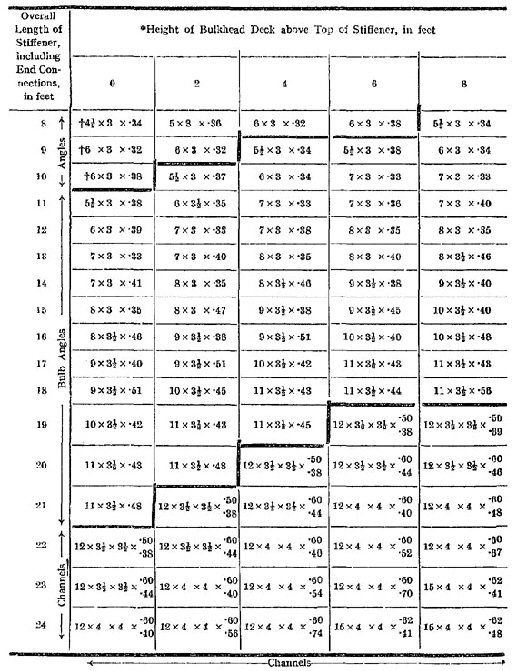

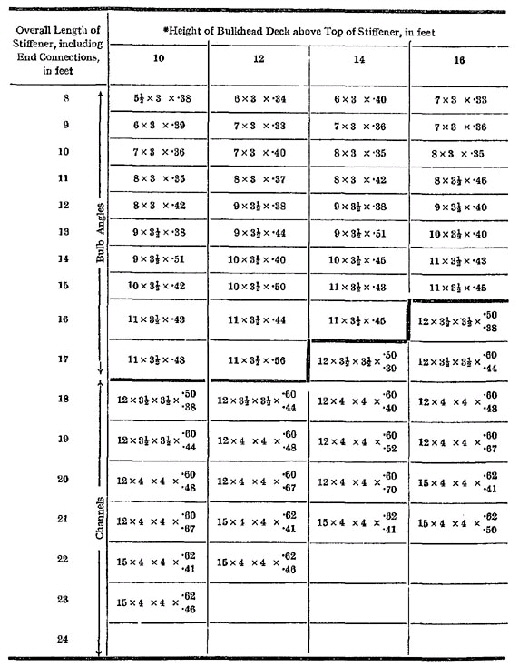

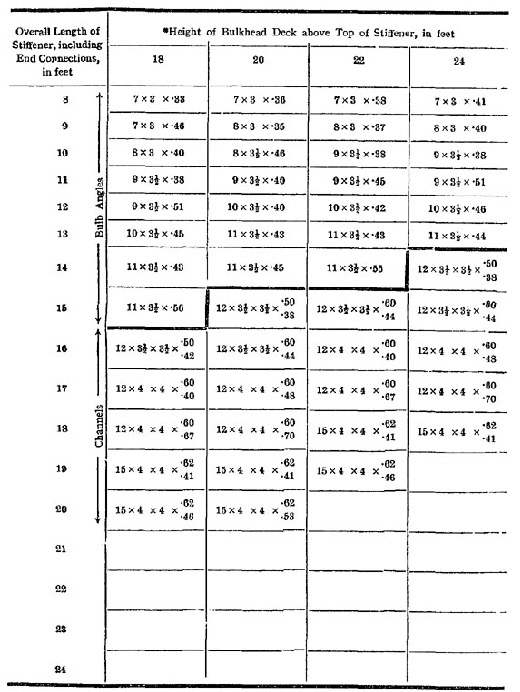

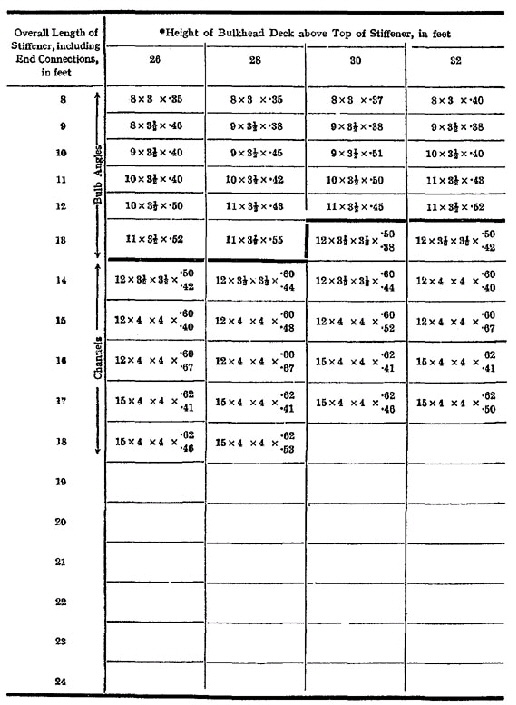

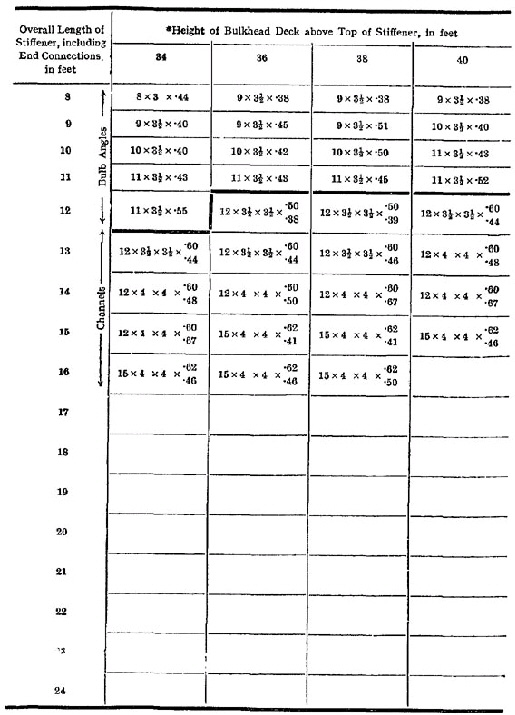

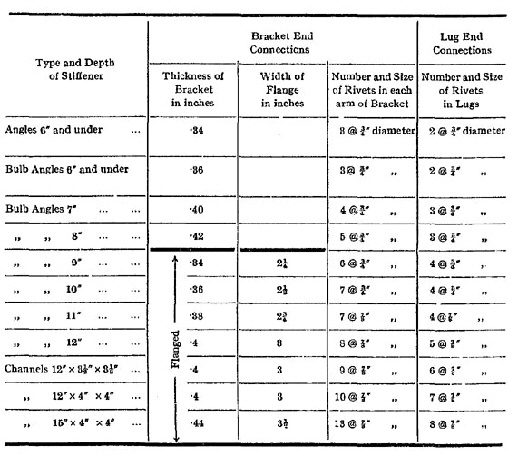

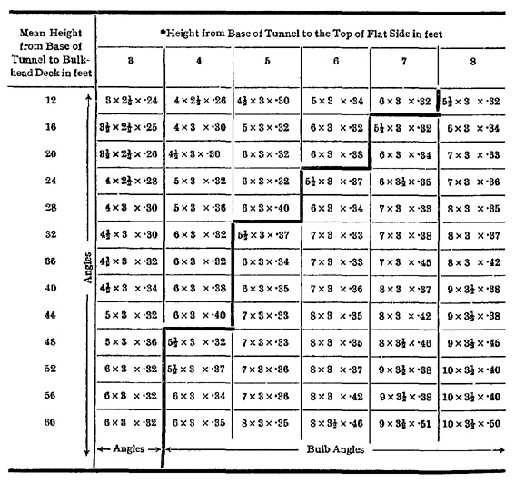

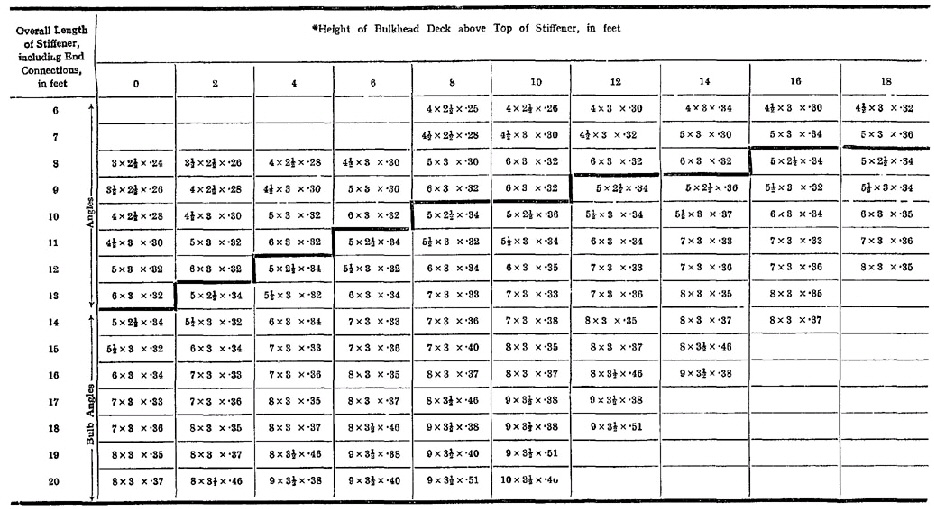

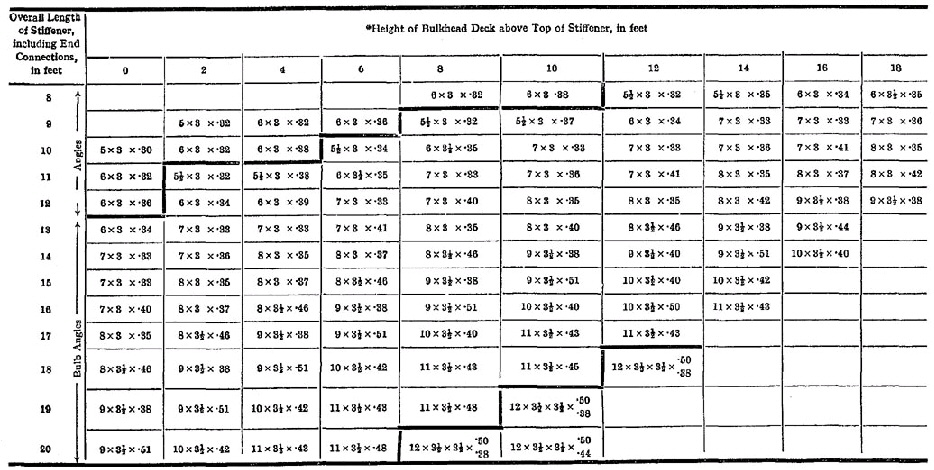

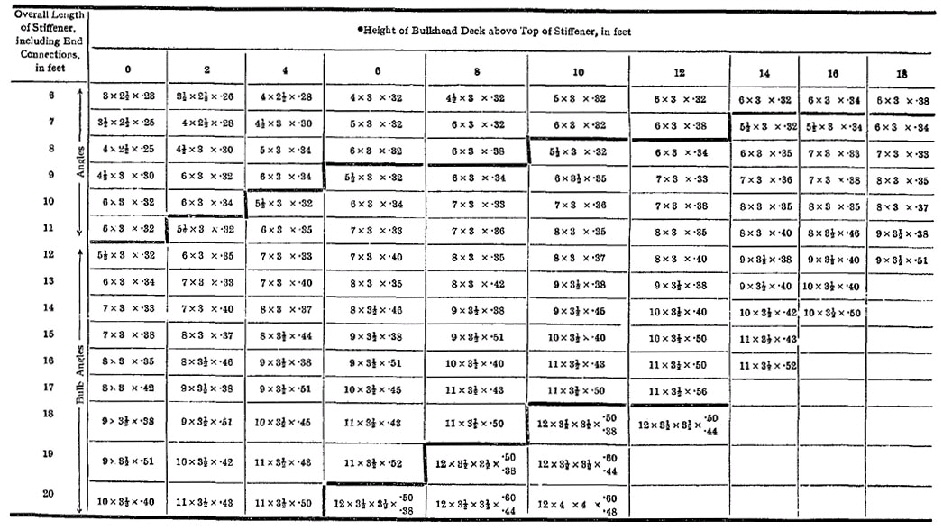

11 Construction of watertight portions of ships | 11.—(1) In every ship to which this Part applies every portion of the ship required by these Rules to be watertight shall be constructed in accordance with such of the requirements of the Fourth Schedule to these Rules as apply to it. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) In every such ship all tanks forming part of the structure of the ship and used for the storage of oil fuel or other liquids including double bottoms, peak tanks, settling tanks and bunkers shall be of a design and construction adequate for that purpose. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 Openings in watertight bulkheads and other structures. | 12.—(1) In every ship of Classes I, II and II(A) the number of openings in bulkheads and other structures required by these Rules to be watertight shall be the minimum compatible with the design and proper working of the ship. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) So far as practicable, trunks installed in connection with ventilation, forced draught or refrigeration systems in any such ship shall not pierce such bulkheads or structures. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Every tunnel above the double bottom, if any, in such a ship whether for access from the crew space to the machinery space, for piping or for any other purpose, which passes through such a bulkhead shall be watertight. The means of access to at least one end of such tunnel, if it may be used as a passage at sea, shall be through a trunkway extending watertight to a height sufficient to permit access above the margin line. The means of access to the other end of the tunnel shall be through a watertight door. No tunnel shall extend through the first subdivision bulkhead abaft the collision bulkhead. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Within spaces containing the main and auxiliary propelling machinery including boilers serving the needs of propulsion and all permanent bunkers, not more than one doorway, apart from the doorways to bunkers and shaft tunnels, may be fitted in each main transverse bulkhead. In case two or more shafts are fitted, the tunnels shall be connected by an inter-communicating passage. There shall be only one doorway between the machinery space and the tunnel spacesin case one or two shafts are fitted and only two doorways in case there are more than two shafts. All such doorways shall be located so as to have their sills as high as practicable. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Doorways, manholes and access openings shall not be fitted in the collision bulkhead below the margin line of any ship of Classes I, II or II(A) or in any other bulkhead which is required by these Rules to be watertight and which divides a cargo space from another cargo space or from a permanent or reserve bunker : Provided that the Minister may permit any such ship to be fitted with doorways in bulkheads dividing two between deck cargo spaces if he is satisfied that ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) the doorways are necessary for the proper working of the ship, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) the number of such doorways in the ship is the minimum compatible with the design and proper working of the ship, and they are fitted at the highest practicable level, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) the outboard vertical edges of such doorways are situated at a distance as far as practicable from the ship's shell plating and in no case less than one-fifth of the breadth of the ship such distance being measured at right angles to the centre line of the ship at the level of the deepest subdivision load water line. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) In every ship of Classes I, II and II(A) bulkheads outside the spaces containing machinery which are required by these Rules to be watertight shall not be pierced by openings which are capable of being closed only by portable bolted plates. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) In every ship of Classes III to VI, inclusive, to which this Part applies, bulkheads required by these Rules to be watertight shall not be pierced by doorways, ventilation trunks or other similar openings. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(8) (a) In every ship to which this Part applies— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) valves and cocks not forming part of a pipe system shall not be fitted in any bulkhead required by these Rules to be watertight ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) if any such bulkhead is pierced by pipes, scuppers, electric cables or other similar fittings, provision shall be made which will ensure that the watertightness of the bulkhead is not thereby impaired ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(iii) lead or other heat sensitive materials shall not be used in systems which penetrate watertight subdivision bulkheads, where deterioration of such systems in the event of fire would impair the watertight integrity of the bulkheads. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) The collision bulkhead of a ship to which this Part applies shall not be pierced below the margin line by more than one pipe : Providedthat in case the forepeak in such a ship is divided to hold two different kinds of liquids, the collision bulkhead may be pierced below the margin line by not more than two pipes. Any pipe which pierces the collision bulkhead of such a ship shall be fitted with a screw-down valve capable of being operated from above the bulkhead deck, the valve chest being secured to the forward side of the collision bulkhead. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

13 Means of closing openings in watertight bulkheads and other structures required to be watertight. | 13.—(1) In every ship of Classes I, II and II(A) efficient means shall be provided for closing and making watertight all openings in bulkheads and other structures required by these Rules to be watertight. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Every door fitted to any such opening shall be a sliding watertight door : Provided that, in any ship of Class I, or in any ship of Class II or II(A) which is not required to be subdivided in accordance with Part III of the Second Schedule to these Rules, hinged watertight doors may be fitted in the following positions :— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) in passenger, crew and working spaces above any deck the underside of which at its lowest point is at least 7 feet above the deepest subdivision load water line ; and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) in any bulkhead, not being a collision bulkhead, which divides two cargo between deck spaces. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Sliding watertight doors referred to in paragraph (2) may have a horizontal or vertical motion and shall be either :— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) hand operated only, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) power operated, when so required by these Rules, as well as hand operated. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Hinged watertight doors fitted in accordance with paragraph (2) (a) shall be fitted with catches, or similar quick action closing devices, capable of being worked from each side of the bulkhead in which the door is fitted. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Where sliding watertight doors are fitted in the position referred to in paragraph (2) (b) such doors shall not be fitted with remote control devices, and every watertight door which is fitted in such a position and which is accessible while the ship is at sea, shall be fitted with efficient locking arrangements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) Every door required by these Rules to be watertight shall be capable of being secured by means other than bolts and of being closed by means other than gravity. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) In every ship of Classes I, II and II(A) watertight doors fitted in bulkheads between permanent and reserve bunkers, other than the doors referred to in Rule 14 (4) shall always be accessible. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

14 Means of operating sliding watertight doors. | 14.—(1) If in any ship of Class I, II or II(A) which is not required to be subdivided in accordance with Part III of the Second Schedule to these Rules, any sliding watertight door fitted in a bulkhead is in a position which may require it to be opened at sea and the sill thereofbelow the deepest subdivision load water line, the following provisions shall apply :— | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) in case the number of such doors (excluding doors at entrances to shaft tunnels) exceeds five, all the doors and those at the entrances to shaft tunnels, ventilation, forced draught or similar ducts shall be power operated and shall be capable of being simultaneously closed from a single position situated on the navigating bridge ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) in case the number of such doors (excluding doors at entrances to shaft tunnels) is greater than one, but does not exceed five— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) where the ship has no passenger spaces below the bulkhead deck—all the doors may be hand operated, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) where the ship has passenger spaces below the bulkhead deck—all the doors and those at the entrances to shaft tunnels, ventilation or forced draught or similar ducts, shall be power operated and shall be capable of being simultaneously closed from a single position situated on the navigating bridge ; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) in any ship where there are only two such doors and they lead into or are within the space containing machinery, the Minister may permit the doors to be hand operated only. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Sliding watertight doors the sills of which are above the deepest subdivision load water line and below the line specified in Rule 13 (2) (a) shall be sliding doors and may be hand operated, except in vessels to which paragraph (3) applies. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) In every ship of Class II or II (A) which is subdivided in accordance with Part III of the second Schedule to these Rules all sliding watertight doors shall be operated by power and shall be capable of being simultaneously closed from a single position situated on the navigating bridge : Provided that if there is only one such door in any such ship and it is in the space containing machinery, it shall not be required to be operated by power. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) In case in any ship of Class I, II or II (A) any sliding watertight doors which may be opened at sea for the purpose of trimming coal are fitted between bunkers in the between decks below the bulkhead deck, such doors shall be operated by power. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) In case in any ship of Class I, II or II (A) a trunkway, being part of a refrigeration, ventilation or forced draught system, is carried through more than one transverse watertight bulkhead and the sills of the openings of such trunkways are less than 7 feet above the deepest subdivision load water line, the sliding watertight doors at such openings shall be operated by power. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) (a) In case a sliding watertight door is required by these Rules to be operated by power from a single position on the navigating bridge, the power system shall be so arranged that the door can also be operated by power at the door itself. The arrangement shall be such that the door will close automatically if opened at the door itself after being closed from the single position on the navigating bridge and will be capable of being kept closed at the door itself notwithstanding that an attempt may be made to open it from such single position. Handles for controlling the power system shall be provided at both sides of the bulkhead in which the door is situated and shall be so arranged that any person passing through the doorway is able to hold both handles in the open position simultaneously without being able to set the closing mechanism in operation accidentally. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Sliding watertight doors shall be capable of closing as expeditiously as possible, but the rate of closing shall not be so rapid as to be a danger to persons passing through the opening. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) (a) In every ship of Classes I, II and II (A) there shall be at least two independent sources of power for opening and closing all sliding watertight doors which are required by these Rules to be operated by power, and each power unit shall be sufficient to operate simultaneously all such doors in the ship. The power shall be controlled from a single position on the navigating bridge, and there shall be provided at such position suitable indicators for checking that each of the two sources of power is capable of giving the required service satisfactorily. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Where the sources of power are hydraulic there shall be two pumps each of which shall be capable of closing all watertight doors in not more than 60 seconds. In addition, there shall be for the whole installation hydraulic accumulators of sufficient capacity to operate all such doors at least three times, that is to say from the open to the closed position, from the closed to the open position and from the open to the closed position. The fluid used shall be one which does not freeze at any temperature liable to be encountered by the ship during its service. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(8) In every ship of Classes I, II and II (A) every sliding watertight door which is operated by power shall be provided with efficient hand-operating gear having an all-round crank motion, or some other movement providing the same guarantee of safety, capable of being operated on each side of the door itself and at an accessible position above the bulkhead deck. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(9) In every ship of Classes I, II and II (A) if a sliding watertight door is not required to be operated by power, it shall be provided with efficient hand-operating gear having an all-round crank motion, or some other movement providing the same guarantee of safety, capable of being operated on each side of the door itself and at an accessible position above the bulkhead deck. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(10) Where hand-operating gear is fitted in accordance with paragraphs (8) and (9), the Minister may permit any sliding watertight door to be operated on one side only, if the requirements of the said paragraphs cannot be met owing to the layout of the spaces. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(11) In every ship of Classes I, II and II (A)—(a) the time necessary for the complete closure of any door by means of hand-operating gear with the vessel upright shall not exceed 90 seconds, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) the hand-operating gear shall be of such a design that the doors can be closed and opened from each of the required operating positions. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(12) In every ship of Classes I, II and II (A) the hand-operating gear for operating the sliding watertight doors in the machinery space from above the bulkhead deck shall be placed outside the machinery space unless such a position is inconsistent with the efficient arrangement of the necessary gearing. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(13) In every ship of Classes I, II and II (A) the means of operation of any watertight door, whether power operated or not, shall be capable of closing the door when the ship is listed to 15 degrees either way. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

15 Watertight doors: Signals and communications. | 15.—(1) Every sliding watertight door fitted in a ship of Class I, II or II (A) shall be connected with an indicator at each position from which the door may be closed, other than at the door itself, showing when the door is open and when it is closed. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) There shall be provided in connection with every door mentioned in paragraph (1) which is operated by power a means of giving an audible warning signal at the door itself when the door is about to be closed. The arrangement shall be such that one movement of the operating handle at the position from which the door is about to be closed will be sufficient to sound the signal and to close the door, the signal preceding the movement of the door by an interval sufficient to allow the movement of persons and articles away from the door. The signal shall continue to sound until the door is completely closed. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) If any door required by these Rules to be watertight is not capable of being operated from a single position on the navigating bridge, means of communication by telegraph, telephone or any other direct means shall be provided whereby the officer of the watch may communicate with the person responsible for the closing of the door. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

16 Construction of watertight doors. | 16.—(1) Every door required by these Rules to be watertight shall be of such design, material and construction as will maintain the integrity of the watertight bulkhead in which it is fitted. Any such door giving direct access to any space which may contain bunker coal shall, together with its frame, be made of cast or mild steel. Any such door in any other position shall, together with its frame, be made of cast or mild steel or cast iron. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Every sliding watertight door shall be fitted with rubbing faces of brass or similar material which may be fitted either on the door itself or on the door frame, and which, if they are less than one inch in width, shall be fitted in recesses. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) In case screw gear is used for operating a sliding watertight door, the screw shall work in a nut of suitable metal which is resistant to corrosion. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) The frame of every vertically sliding watertight door shall have no groove at the bottom thereof in which dirt may lodge. The bottom of such a frame, in case it is of skeleton form, shall be so arranged that dirt cannot lodge therein. The bottom edge of every such door shall be tapered or bevelled. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Every vertically sliding watertight door which is operated by power shall be so designed and fitted that, if the power supply ceases, there shall be no danger of the door dropping. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) Every horizontally sliding watertight door shall be so installed as to prevent its moving if the ship rolls, and if necessary a clip or other suitable device shall be provided for that purpose. The device shall not interfere with the closing of the door when the door is required to be closed. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) The frame of every watertight door shall be properly fitted to the bulkhead in which the door is situated, and the jointing material between the frame and the bulkhead shall be of a type which will not deteriorate or be injured by heat. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(8) Every watertight door, being a coal-bunker door, shall be provided with screens or other devices to prevent coal from interfering with its closing. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

17 Openings in the shell plating below the margin line. | 17.—(1) In every ship to which this Part applies the number of side scuttles, scuppers, sanitary discharges and other openings in the shell plating below the margin line shall be the minimum compatible with the design and proper working of the ship. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The arrangements for closing each such opening below the margin line shall be consistent with its intended purpose and shall be such as will ensure watertightness. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) (a) In every ship of Classes I, II and II (A) the number of side scuttles below the margin line which are capable of being opened shall be the minimum compatible with the requirements of the proper operation of the ship. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) In case in a between decks of a ship of Classes I, II or II (A) the sills of any side scuttles are below a line drawn parallel to the bulkhead deck at side and having its lowest point 2½ per cent. of the breadth of the ship above the deepest subdivision load water line, every side scuttle in that between decks shall be of a non-opening type. If in a between decks of such a ship all the sills of the side scuttles are above the said line, every side scuttle in that between decks shall be either of a non-opening type or incapable of being opened except by a person authorised to do so by the master of the ship. No side scuttle shall be fitted so that its sill is below the deepest subdivision load water line. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) In every ship of Classes III to VI, inclusive, to which this Part applies all side scuttles below the margin line shall be of a non-opening type. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) In every ship to which this Part applies every side scuttle below the margin line shall be fitted with an efficient hinged deadlight permanently attached so that it can be readily and effectively closed and secured watertight: Provided that abaft a point one-eighth of the length of the ship from the forward perpendicular and above a line drawn parallel to the bulkhead deck at side and having its lowest point at a height of 12 feet plus 2½ per cent. of the breadth of the ship above the ship's deepest subdivision load water line, deadlights may for the purpose of these Rules be portable in crew spaces and in passenger spaces not appropriated for the use of steerage passengers within the meaning of Part III of the Merchant Shipping Act, 1894. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) Side scuttles shall not be fitted below the margin line in any space in a ship to which this Part applies which is appropriated solely to the carriage of cargo or coal. In case side scuttles are fitted in spaces below the margin line which may be appropriated to the carriage either of cargo or of passengers, the side scuttles and their deadlights shall be so constructed as to be incapable of being opened except by a person authorised to do so by the master of the ship. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) Automatic ventilating side scuttles shall not be fitted below the margin line in the shell plating of any ship to which this Part applies. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(8) (a) In every ship to which this Part applies each inlet and discharge led through the shell plating below the margin line shall be fitted with efficient and readily accessible means for preventing the accidental admission of water into the ship. Lead or other heat sensitive materials shall not be used for pipes fitted outboard of shell valves in inlets or discharges, or in any other place where the deterioration of such pipes in the event of fire would give rise to danger of flooding. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Without prejudice to the generality of subparagraph (a), each discharge led through the shell plating from spaces below the margin line, not being a discharge in connection with machinery, shall be provided with either— | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) one automatic non-return valve fitted with a positive means by which it can always be closed from a readily accessible position above the ship's bulkhead deck and with an indicator at the position from which the valve may be closed to show whether the valve is open or closed ; or | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) two automatic non-return valves, the upper of which is so situated above the ship's deepest subdivision load water line as to be always accessible for examination under service conditions and is of a horizontal balanced type which is normally closed. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) Any valve fitted in compliance with the requirements of sub-paragraph (b) which is a geared valve, or the lower of two non-geared valves, shall be secured to the ship's shell plating. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(d) All cocks and valves attached to inlets or discharges mentioned in paragraph (8) (a). other than inlets or discharges connected withmachinery, being cocks or valves fitted below the margin line or the failure of which may affect the subdivision of the ship, shall be made of steel, bronze or other equally efficient material. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(e) Main and auxilary inlets and discharges connected with machinery shall be fitted with readily accessible cocks or valves between the pipes and the ship's shell plating or between the pipes and a fabricated box attached to the shell plating. All such cocks or valves attached to such inlets or discharges and all fittings outboard thereof shall be made of steel, bronze or other suitable ductile material. If made of steel, such cocks and valves shall be protected against corrosion. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(f) Discharge pipes led through the shell plating below the margin line of any ship of Classes I to III, inclusive, shall not be fitted in a direct line between the outboard opening and the connection with the deck, water closet or other similar fitting, but shall be arranged with bends or elbows of substantial metal other than cast iron or lead. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(g) All discharge pipes led through the shell plating below the margin line in a ship to which this Part applies and the valves relating thereto shall be protected from damage. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(h) All bolts connecting cocks, valves, discharge pipes and other similar equipment to the shell plating of a ship to which this Part applies below the margin line shall have their heads outside the shell plating, and shall be either countersunk or cupheaded. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) Efficient means shall be provided for the drainage of all watertight decks below the margin line in a ship to which this Part applies and any drainage pipes shall be so fitted with valves or otherwise arranged as to avoid the danger of water passing from a damaged to an undamaged compartment. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(j) The inboard opening of every ash-shoot, rubbish-shoot and other similar shoot in a ship to which this Part applies shall be fitted with an efficient watertight cover, and, if such opening is below the margin line, it shall also be fitted with an automatic non-return valve in the shoot in a readily accessible position above the ship's deepest subdivision load water line. The valve shall be of the horizontal balanced type, normally closed and provided with local means for securing it in a closed position. The requirements of this sub-paragraph shall not apply to ash ejectors and expellers the inboard openings of which are in the ship's stokehold and necessarily below the deepest subdivision load water line. Such ejectors and expellers shall be fitted with means which will prevent water entering the ship. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(k) Any gangway port, cargo port or coaling port fitted below the margin line of a ship to which this Part applies shall be of adequate strength and its lowest point shall not be below the ship's deepest subdivision load water line. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(9) The Minister may exempt any ship of Classes IV to VI, inclusive, from the requirements of paragraph (8) to the extent that he is satisfied that compliance therewith is unreasonable or imoracticable in the circumstances. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|