S.I. No. 288/1949 - Standard Specification (Solid Concrete Building Blocks Made With Natural Aggregate) Order, 1949.

S.I. No. 288 of 1949. | ||||||||||||||||||||||||||||||||||||||||||||||||||

STANDARD SPECIFICATION (SOLID CONCRETE BUILDING BLOCKS MADE WITH NATURAL AGGREGATE) ORDER, 1949. | ||||||||||||||||||||||||||||||||||||||||||||||||||

I, DANIEL MORRISSEY, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946) hereby order as follows : 1. This Order may be cited as the Standard Specification (Solid Concrete Building Blocks made with Natural Aggregate) Order, 1949. 2.—(1) The specification set forth in Part II of the Schedule to this Order is hereby declared to be the standard specification for the commodity described in Part I of the said Schedule. | ||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The said standard specification may be cited as Irish Standard 20 : 1949. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

SCHEDULE. | ||||||||||||||||||||||||||||||||||||||||||||||||||

PART I. | ||||||||||||||||||||||||||||||||||||||||||||||||||

SOLID CONCRETE BUILDING BLOCKS MADE WITH NATURAL AGGREGATE. | ||||||||||||||||||||||||||||||||||||||||||||||||||

PART II. | ||||||||||||||||||||||||||||||||||||||||||||||||||

SPECIFICATION. | ||||||||||||||||||||||||||||||||||||||||||||||||||

In this specification, the letters I.S., when followed by two sets of numbers, refer to the Irish Standard of which the first is the serial number and the second the year of its promulgation by the Minister for Industry and Commerce. | ||||||||||||||||||||||||||||||||||||||||||||||||||

In this specification, the words " test sieve " used in conjunction with any particular size or number shall mean the British Standard Test Sieve of that size or number as prescribed by the British Standards Institution in its publication of serial number 410 of the year 1943. | ||||||||||||||||||||||||||||||||||||||||||||||||||

SCOPE. | ||||||||||||||||||||||||||||||||||||||||||||||||||

1. This specification relates to pre-cast solid concrete blocks made with natural aggregates and intended for use : | ||||||||||||||||||||||||||||||||||||||||||||||||||

(a) for external walls which are to be protected by rendering or other suitable means, | ||||||||||||||||||||||||||||||||||||||||||||||||||

(b) as a backing to brickwork and masonry, | ||||||||||||||||||||||||||||||||||||||||||||||||||

(c) in panels in steel frame and reinforced concrete buildings. | ||||||||||||||||||||||||||||||||||||||||||||||||||

(d) in internal partition walls, or | ||||||||||||||||||||||||||||||||||||||||||||||||||

(e) for other purposes where high compressive strength or complete resistance to the penetration of moisture is not required. | ||||||||||||||||||||||||||||||||||||||||||||||||||

CEMENT. | ||||||||||||||||||||||||||||||||||||||||||||||||||

2. The cement used in the manufacture of blocks shall comply in all respects with the provisions of I.S. 1 : 1949. | ||||||||||||||||||||||||||||||||||||||||||||||||||

AGGREGATE. | ||||||||||||||||||||||||||||||||||||||||||||||||||

3. The aggregates used in the manufacture of blocks shall consist of naturally occurring sand, gravel or stone, crushed or uncrushed, or a combination thereof. They shall be hard, strong, durable, clean and free from adherent coatings, and shall not contain excessive quantities of flat or elongated particles. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The aggregates shall all pass through a ¾ in. test sieve. All aggregates may be used with or without sand. The sand, i.e. fine aggregate passing a 3/16 in. test sieve, shall not contain more than 10 per cent. passing No. 100 test sieve. | ||||||||||||||||||||||||||||||||||||||||||||||||||

(a) Harmful Impurities. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The aggregate shall not contain harmful material in sufficient quantity to affect adversely the strength or durability of the concrete. Mica, shale or similar laminated materials, or soft particles, shall not be present in such a form or in such quantity as to affect adversely the concrete. | ||||||||||||||||||||||||||||||||||||||||||||||||||

When tested in accordance with the method given in Appendix A the quantity of harmful impurities passing a No. 200 test sieve shall not exceed (i) in the case of fine aggregate 3 per cent. for natural sand and 5 per cent. for crushed stone, and (ii) in the case of coarse aggregate 1 per cent. | ||||||||||||||||||||||||||||||||||||||||||||||||||

Fine aggregate when tested for organic impurities in accordance with the method given in Appendix B shall not show a depth of colour exceeding that of the reference solution prepared as described in Appendix B. | ||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Frost Resistance | ||||||||||||||||||||||||||||||||||||||||||||||||||

Coarse aggregates, i.e. aggregate retained on a 3/16 in. test sieve, shall not be of a type that is liable to suffer from the action of frost. | ||||||||||||||||||||||||||||||||||||||||||||||||||

SURFACE TEXTURE. | ||||||||||||||||||||||||||||||||||||||||||||||||||

4. The surface texture of blocks to be rendered shall be such as to provide a suitable key for rendering. | ||||||||||||||||||||||||||||||||||||||||||||||||||

MIX. | ||||||||||||||||||||||||||||||||||||||||||||||||||

5. The blocks shall contain not more than 112 lb. of cement to 7½ cubic feet of combined fine and coarse aggregate. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The cement and aggregate used in the manufacture of the blocks shall be thoroughly mixed. | ||||||||||||||||||||||||||||||||||||||||||||||||||

CURING. | ||||||||||||||||||||||||||||||||||||||||||||||||||

6. The blocks shall be cured for such a period as may be necessary to ensure that they shall conform to the requirements of Clauses 10 and 11. | ||||||||||||||||||||||||||||||||||||||||||||||||||

DIMENSIONS. | ||||||||||||||||||||||||||||||||||||||||||||||||||

7. The dimensions of blocks other than blocks of special type shall be within the limits given in Table 1 for each nominal size. | ||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE 1. | ||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||

SPECIAL TYPES. | ||||||||||||||||||||||||||||||||||||||||||||||||||

8. Blocks of special type shall be of the dimensions and shape specified by the purchaser. | ||||||||||||||||||||||||||||||||||||||||||||||||||

WEIGHT. | ||||||||||||||||||||||||||||||||||||||||||||||||||

9. The weight of any block other than a block of special type shall not exceed 85 lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||

COMPRESSIVE STRENGTH. | ||||||||||||||||||||||||||||||||||||||||||||||||||

10. The compressive strength of the blocks, when determined in the manner described in Appendix C, shall be not less than 500 lb. per sq. inch. | ||||||||||||||||||||||||||||||||||||||||||||||||||

ABSORPTION AND MOISTURE CONTENT. | ||||||||||||||||||||||||||||||||||||||||||||||||||

11. The absorption of the blocks, tested in accordance with the method described in Appendix D, shall be not more than 15 lb. per cubic foot. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The moisture content of the blocks, tested in accordance with the method described in Appendix D, shall not exceed 40 per cent. of the absorption. | ||||||||||||||||||||||||||||||||||||||||||||||||||

MANUFACTURER'S CERTIFICATE. | ||||||||||||||||||||||||||||||||||||||||||||||||||

12. The manufacturer shall satisfy himself that the blocks conform to the requirements of this specification and, if requested, shall forward a certificate to this effect to the purchaser. | ||||||||||||||||||||||||||||||||||||||||||||||||||

SAMPLING AND COST OF SAMPLES. | ||||||||||||||||||||||||||||||||||||||||||||||||||

13. The purchaser may select 11 blocks for testing from every consignment of 1,000 blocks or part thereof. The blocks required for testing shall be supplied by the manufacturer free of charge. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The purchaser may select for testing, samples of the aggregates used in the manufacture of the blocks. The weight of the sample shall be 1 cwt. in the case of fine aggregate and 2 cwt. in the case of coarse aggregate. Samples of aggregates shall be supplied, free of charge. | ||||||||||||||||||||||||||||||||||||||||||||||||||

INDEPENDENT TEST. | ||||||||||||||||||||||||||||||||||||||||||||||||||

14. If the purchaser requires independent tests, he shall take samples for testing before or immediately after delivery, and shall make arrangements for tests to be carried out in accordance with this specification. | ||||||||||||||||||||||||||||||||||||||||||||||||||

COST OF TESTS. | ||||||||||||||||||||||||||||||||||||||||||||||||||

15. The cost of the tests shall be borne : | ||||||||||||||||||||||||||||||||||||||||||||||||||

(a) by the manufacturer in the event of results showing that the blocks do not comply with this specification, | ||||||||||||||||||||||||||||||||||||||||||||||||||

(b) by the purchaser in the event of results showing that the blocks comply with this specification. | ||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX A. | ||||||||||||||||||||||||||||||||||||||||||||||||||

DETERMINATION OF AMOUNT OF MATERIAL PASSING A NO. 200 TEST SIEVE. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The sample for testing shall be thoroughly mixed and shall contain sufficient moisture to prevent segregation. A representative sample, sufficient to yield not less than the appropriate weight of dried material, as shown in Table 2, shall be selected from the sample for testing. | ||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE 2—SIZE OF SAMPLE. | ||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||

The sample shall be dried to constant weight at a temperature between 100° C. and 110° C. and weighed (Weight A). The material shall be deemed to be of constant weight when the difference in successive weighings at the temperature specified at intervals of four hours does not exceed 0·01 per cent. of the weight of the material. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The sample shall then be placed in a pan or container and covered with water. The pan or container shall be large enough to permit of vigorous agitation without accidental loss of any part of the sample or of water. The contents of the container shall be agitated vigorously so that the fine material is brought into suspension and the wash water shall then be poured immediately over a No. 14 test sieve and a No. 200 test sieve arranged with the coarser sieve on top. Care shall be taken to avoid decantation of the coarse particles of the sample. The operation shall be repeated until the wash water is clear. All material retained on the sieves shall be returned to the washed sample. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The washed material shall be dried to constant weight at a temperature between 100° C. and 110° C. and weighed (Weight B). | ||||||||||||||||||||||||||||||||||||||||||||||||||

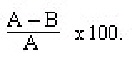

The results shall be calculated from the following formula : | ||||||||||||||||||||||||||||||||||||||||||||||||||

Percentage of material passing a No. 200 test sieve = | ||||||||||||||||||||||||||||||||||||||||||||||||||

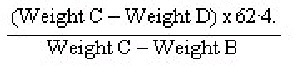

When check determinations are desired, the wash water shall be either evaporated to dryness or filtered through tared filter paper which subsequently shall be dried and the residue weighed (Weight C). | ||||||||||||||||||||||||||||||||||||||||||||||||||

The percentage shall be calculated from the following formula : | ||||||||||||||||||||||||||||||||||||||||||||||||||

Percentage of material passing a No. 200 test sieve = | ||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX B. | ||||||||||||||||||||||||||||||||||||||||||||||||||

DETERMINATION OF ORGANIC IMPURITIES. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The aggregate shall be used as delivered without drying. A representative sample weighing 1 lb. shall be taken from the sample to be tested. A 12 oz. clear-glass bottle graduated to ½ oz. shall be filled from the sample to the 4 ½ oz. mark. A 3 per cent. solution of sodium hydroxide in water shall be added until the volume of the sand and liquid, after shaking, is 7 fluid ounces. The bottle shall be stoppered, shaken vigorously and then allowed to stand for 24 hours. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The amount of organic impurity shall be assessed by the extent to which the liquid above the sand is darker in colour than the reference solution. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The reference solution shall be prepared by adding 2·5 ml. of a 2 per cent. solution of tannic acid in 10 per cent. alcohol to 97·5 ml. of a 3 per cent. sodium hydroxide solution. The solution shall then be placed in a 12 oz. bottle, stoppered, shaken vigorously and allowed to stand for 23 hours. It shall then be shaken and allowed to stand for a further 1 hour before comparison with the solution above the sand. | ||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX C. | ||||||||||||||||||||||||||||||||||||||||||||||||||

METHOD OF CARRYING OUT COMPRESSIVE STRENGTH TEST. | ||||||||||||||||||||||||||||||||||||||||||||||||||

Five whole blocks taken at random from the samples selected for test shall be used for determining the compressive strength. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The determination shall be made by applying a load to the faces of the block which are at right angles to the height, i.e. the dimension indicated as the height in Clause 7 of this specification. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The over-all dimensions of each of these faces shall be measured to the nearest 0·05 in. The area of the smaller face shall be taken as the area for the purpose of calculating the compressive strength. | ||||||||||||||||||||||||||||||||||||||||||||||||||

One of these two faces shall be capped with mortar in the following manner : A quantity of mortar, made of 1 part by volume of Portland Cement and 1 part of Plaster of Paris mixed with sufficient water to spread evenly shall be placed on a plain surface which has beencoated with oil. The face to be capped shall be placed on this mortar and the block, held with its axis at right angles to the oiled surface, shall be pressed down firmly with a single motion. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The average thickness of the cap after the extruded mortar has been removed and the edges made true shall be not more than 1/8 in. Imperfect caps shall be removed and replaced by new ones. Patching of caps after setting shall not be permitted. | ||||||||||||||||||||||||||||||||||||||||||||||||||

When the caps are aged two hours the blocks shall be immersed in water at a temperature of 58° F. to 64° F. for at least twenty-four hours before testing. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The block shall be placed in the testing machine so that the direction of loading shall be at right angles to the capped surface. The load shall be applied axially at a uniform rate of 2,000 lb. per square inch per minute. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The maximum load in pounds supported by the block before failure occurs, divided by the area in square inches, shall be taken as the compressive strength of the block. The arithmetic mean of the compressive strengths of the five blocks shall be taken as the compressive strength of the blocks for the purpose of Clause 10 of this specification. | ||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX D. | ||||||||||||||||||||||||||||||||||||||||||||||||||

METHOD FOR THE DETERMINATION OF ABSORPTION AND MOISTURE CONTENT. | ||||||||||||||||||||||||||||||||||||||||||||||||||

Three of the blocks taken in accordance with Clause 13 shall be tested and three shall be stored in airtight containers at normal room temperature for repeat tests if required. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The block shall be weighed on a balance sensitive to ¼ lb. (Weight A). | ||||||||||||||||||||||||||||||||||||||||||||||||||

The block shall be completely immersed in water at a temperature of 58° F. to 64° F. for twenty-four hours. The block shall then be weighed while suspended with a metal wire and completely submerged in water (Weight B). It shall be removed from the water, allowed to drain for one minute by placing it on a 3/8 inch or coarser wire mesh, visible surface water removed with a damp cloth, and the block immediately weighed (Weight C). | ||||||||||||||||||||||||||||||||||||||||||||||||||

The block shall then be dried in an oven at 100° C. to 115° C. and weighed at twenty-four hour intervals until the loss of weight does not exceed 1 per cent. in a twenty-four hour period (Weight D). | ||||||||||||||||||||||||||||||||||||||||||||||||||

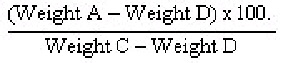

The absorption of the block shall be calculated as follows : | ||||||||||||||||||||||||||||||||||||||||||||||||||

Absorption, lb. per cu. ft.= | ||||||||||||||||||||||||||||||||||||||||||||||||||

The arithmetic mean of the absorption of three blocks shall be taken as the absorption of the blocks for the purpose of Clause 11 of this specification. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The moisture content of the block expressed as a percentage of the total absorption shall be calculated as follows : | ||||||||||||||||||||||||||||||||||||||||||||||||||

Moisture Content, per cent. = | ||||||||||||||||||||||||||||||||||||||||||||||||||

The arithmetic mean of the moisture content of three blocks shall be taken as the moisture content of the blocks for the purpose of Clause 11 of this specification. | ||||||||||||||||||||||||||||||||||||||||||||||||||

GIVEN under my Official Seal this 4th day of November, 1949. | ||||||||||||||||||||||||||||||||||||||||||||||||||

DANIEL MORRISSEY, | ||||||||||||||||||||||||||||||||||||||||||||||||||

Minister for Industry and Commerce. | ||||||||||||||||||||||||||||||||||||||||||||||||||