S.I. No. 348/1953 - Merchant Shipping (Grain) Rules, 1953.

S.I. No. 348 of 1953. | ||||||||||||||||||||||||||||||||

MERCHANT SHIPPING (GRAIN) RULES, 1953. | ||||||||||||||||||||||||||||||||

I, SEÁN F. LEMASS, Minister for Industry and Commerce, in exercise of the powers conferred upon me by subsection (3) of section 39 of the Merchant Shipping (Safety Convention) Act, 1952 (No. 29 of 1952), hereby make the following Rules :— 1. These Rules may be cited as the Merchant Shipping (Grain) Rules, 1953. 2. These Rules supersede all regulations made under section' 453 of the Merchant Shipping Act, 1894, before the coming into operation of these Rules which said regulations are accordingly hereby revoked. 3. These Rules shall come into operation on the 19th day of November, 1953. 4. Every precaution set forth in the Schedule to these Rules is hereby prescribed as being, subject to the provisions of the said Schedule, a precaution to be treated for the purposes of subsections (1) and (2) of the said section 39 as a necessary or reasonable precaution to prevent grain from shifting, in the case of ships of the following classes :— | ||||||||||||||||||||||||||||||||

(a) ships which are loaded with grain within any port in the State ; | ||||||||||||||||||||||||||||||||

(b) ships which, having been loaded with grain outside the State, enter any port in the State so laden. 5. Where these Rules require that a particular fitting, appliance or apparatus, or type thereof, shall be fitted or carried in a ship or that any particular provision shall be made, the Minister for Industry and Commerce may allow any other fitting, appliance or apparatus, or type thereof, to be fitted or carried, or any other provision to be made in that ship if he is satisfied that such other fitting, appliance or apparatus, or type thereof, or provision is at least as effective as that required by these Rules. | ||||||||||||||||||||||||||||||||

|

SCHEDULE. | ||||||||||||||||||||||||||||||||

DEFINITIONS. | ||||||||||||||||||||||||||||||||

1. In this Schedule :— | ||||||||||||||||||||||||||||||||

" bin " means a completely enclosed section of cargo space in the 'tween decks or superstructure of the ship ; | ||||||||||||||||||||||||||||||||

" grain " includes wheat, maize, oats, rye, barley, rice, pulses and seeds ; | ||||||||||||||||||||||||||||||||

" heavy grain " means all grain other than oats, light barley and cotton seed ; | ||||||||||||||||||||||||||||||||

" light barley " means barley which weighs 51·575 lb. or less per bushel of 1·2837 cu. ft. | ||||||||||||||||||||||||||||||||

SHIFTING BOARDS, UPRIGHTS, ETC. | ||||||||||||||||||||||||||||||||

Shifting Boards. | ||||||||||||||||||||||||||||||||

2. Shifting boards shall be of a minimum thickness of 2 in. of good sound timber, and fitted grain-tight. They shall be supported by uprights. | ||||||||||||||||||||||||||||||||

3. The maximum unsupported span to be allowed for shifting boards of various thicknesses shall be as follows :— | ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

4. Shifting boards shall be securely housed at each bulkhead by means either of permanent angle bars, or of wood cants not less than 6 in. in width and 3 in. in thickness and suitably shored. | ||||||||||||||||||||||||||||||||

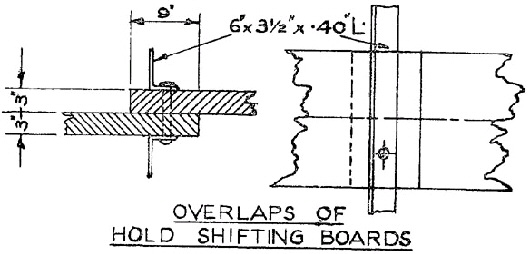

5. Where 2½ in. or 3 in. shifting boards are used, the boards may be butt-jointed in way of the uprights, and at least 4 in. of plank shall be supported. Where 2 in. shifting-boards are used the joints shall overlap by at least 9 in. in way of the uprights. | ||||||||||||||||||||||||||||||||

6. Where no permanent arrangements are made for grain-tight filling between the beams, wood filling pieces of the same thickness as the shifting boards shall be fitted grain-tight between the beams, and shall be secured in place by cleats or scabs at both ends and fitted both sides. The cleats or scabs shall be at least 2 in. x 4 in. in size and shall extend the full depth of the filling piece and as much again below, and be securely spiked or bolted to the shifting boards and filling pieces. | ||||||||||||||||||||||||||||||||

Uprights. | ||||||||||||||||||||||||||||||||

7. Wood uprights shall not be less than 10 in. in width and 2 in. in thickness. | ||||||||||||||||||||||||||||||||

8. Uprights shall be cleated to the tanktop or ceiling where fitted, and when the upright is not securely housed at the top the uppermost supporting shores or stays shall not be more than 18 in. down from the deck or top of the upright. | ||||||||||||||||||||||||||||||||

9. If a tier of closely spaced pillars which serves as a principal support to the deck over in a hold or compartment is utilized for supporting the shifting boards at the middle line and if the pillars are not reeled or staggered, additional support shall be provided by means of hook-bolts and vertical tieplates or uprights secured to the pillars. Such tieplates shall consist of plates not less than 3 in. in width and ½ in. in thickness and shall be through-bolted at intervals of not more than 3 ft. | ||||||||||||||||||||||||||||||||

10. The horizontal distances between the centres of uprights shall be as specified in paragraph 3 of this Schedule. Wood uprights used in association with wire stays shall be not less than 11 in. in width and 3 in. in thickness. The construction and dimensions of angle bar uprights used in association with wire stays shall conform to the specification and method set forth in sub-paragraph (a) of this paragraph or to one of the specifications and to the method set forth in sub-paragraph (b) thereof :— | ||||||||||||||||||||||||||||||||

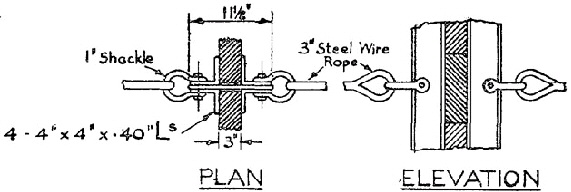

(a) Each upright shall consist of four angle bars 4 in. x 4in. x ·40 in. and steel plate 11½ in. x ·50 in. riveted to form one complete structure allowing 4 in. housings on both forward and after sides. Brackets riveted to head and heel shall be fitted, each to take five 7/8 in. bolts with corresponding lugs or angles on tanktop, tunnel top and hatch webs. | ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

Vertical angle bars shall be connected at head and heel to the tanktop, tunnel top, deck beams, and hatch webs by angle lugs having two 7/8 in. bolts in each angle bar upright and fastenings of equal strength to tanktop, tunnel top, deck beams and hatch webs. The vertical angle bars shall be bolted together through the shifting boards by 7/8 in. bolts approximately 4 ft. apart. | ||||||||||||||||||||||||||||||||

Shores and Stays. | ||||||||||||||||||||||||||||||||

11. Wood uprights shall be supported by steel wire rope stays set up at the ship's side, or by wood shores securely heeled against the permanent structure of the ship. All wood shores shall be of good sound timber in a single piece. | ||||||||||||||||||||||||||||||||

Shores. | ||||||||||||||||||||||||||||||||

12. The vertical spacing of wood shores shall be as follows :— | ||||||||||||||||||||||||||||||||

Except as provided in paragraph 8 of this Schedule the uppermost shore shall be not more than 7 ft. below the top of the upright and succeeding shores shall be spaced not more than 7 ft. apart measured vertically from the uppermost shore downwards, except that a distance of 8ft. shall be permitted between the lowest shore and the heel support. Shores may be heeled on the tanktop or ceilings if the heels are secured by cleats or cants and efficiently braced against the permanent structure. Shores shall not be heeled directly against the ship's side plating. | ||||||||||||||||||||||||||||||||

13. Subject to the provisions of paragraphs 14 and 15 of this Schedule the sizes of wood shores shall be as follows :— | ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

* Securely bridged at approximately mid-length. | ||||||||||||||||||||||||||||||||

Spliced shores shall not be used. | ||||||||||||||||||||||||||||||||

14. Subject to the provisions of paragraph 15 of this Schedule, if the spacings of the uprights or shores are less than those respectively referred to in paragraphs 3 and 12 of this Schedule the sizes of the shores may be reduced in proportion. | ||||||||||||||||||||||||||||||||

15. Where their angle from the horizontal does not exceed 10° the shores fitted shall be of the sizes specified in paragraph 13 of this Schedule. Where, by reason of the construction of the ship, their angle from the horizontal exceeds 10° then the next larger size of shore to that required by its length shall be fitted. In no case shall the angle between any shore and the horizontal exceed 45°. | ||||||||||||||||||||||||||||||||

Stays. | ||||||||||||||||||||||||||||||||

16. One stay on each side of each upright shall be fitted in holds 20 ft. and under in depth and shall be placed at a distance below the deck of approximately one-third from under deck. In holds over 20 ft. in depth two stays on each side of each upright shall be fitted the upper stays being placed at a distance below the deck of approximately one-quarter of the depth of the hold and the lower stays at half the depth of the hold. For the purposes of this paragraph depths shall be measured to top of floors, inner bottom or tunnel top, as the case may be. | ||||||||||||||||||||||||||||||||

17. When stays are used the following provisions shall apply :— | ||||||||||||||||||||||||||||||||

(a) The stays shall be of 3 in. circumference flexible steel wire rope and shall be fitted horizontally. | ||||||||||||||||||||||||||||||||

(b) The rigging screws shall be 1¼ in. in diameter and shall be fitted in accessible positions. | ||||||||||||||||||||||||||||||||

(c) The shackles shall be 1 in. | ||||||||||||||||||||||||||||||||

(d) The eye bolts through the wood or angle bar uprights shall be 1¼ in. | ||||||||||||||||||||||||||||||||

(e) 7/8 in. screw bolts and nuts shall be provided as may be necessary for securing the wood uprights or steel angle bars. | ||||||||||||||||||||||||||||||||

(f) Either eye plates of 1 in. thickness shall be securely riveted to the side stringers or frames or 1 in. shackles passed through the frame. | ||||||||||||||||||||||||||||||||

18. If any shifting boards do not extend to the full depth of the hold the shifting boards and their uprights shall be supported or stayed so as to be as efficient as shifting boards which extend to the full depth of the hold. | ||||||||||||||||||||||||||||||||

Construction of Feeders, Bins and Bulkheads. | ||||||||||||||||||||||||||||||||

19. Feeders, bins and bulkheads shall be of sufficient strength to withstand the pressure due to the head of grain contained therein and shall be grain-tight. | ||||||||||||||||||||||||||||||||

20. Ships having one or more decks with any continuous hold, whether forward or aft, with two hatches to that hold shall have a well-constructed bulkhead extending from side to side of the ship between the two hatches to divide the hold. | ||||||||||||||||||||||||||||||||

21. Wood feeders, wing feeders and bin bulkheads shall be constructed either :— | ||||||||||||||||||||||||||||||||

(a) of planks which have been worked vertically and which are not less than 2½ in. thickness ; when the vertical unsupported span of the planks exceeds 8 ft. the thickness thereof shall be increased proportionately or proportional additional stiffening shall be fitted ; or | ||||||||||||||||||||||||||||||||

(b) of framing lined with grain-tight boards 2 in. in thickness or two 1 in. layers of shiplap, laid horizontally with broken joints ; the framing shall where possible be placed inside the hatch coamings and shall be not less that 4 in. x 6 in. laid on edge spaced not more that 2 ft. apart centre to centre. | ||||||||||||||||||||||||||||||||

The planks at the corners shall be well secured to substantial vertical cants. | ||||||||||||||||||||||||||||||||

22. If the depth of the hatch end beams or coamings exceeds 15 in. below the surface of the deck, feeding holes shall be provided to allow the grain to flow through the coamings into the hold or 'tween decks. When the depth of the coamings below the surface of the deck exceeds 15 in. and does not exceed 18 in. feeding holes 2 in. in diameter shall be provided. When the depth exceeds 18 in. feeding holes of 3½ in. diameter shall be provided. Feeding holes shall be spaced approximately 2 ft. apart. | ||||||||||||||||||||||||||||||||

23. Engine-room and stokehold bulkheads and donkey boiler recesses, where subjected to heat, shall be sheathed with wood and made grain-tight. An air space of at least 6 in. shall be left between the bulkhead and the sheathing and a box trunk ventilator 6 in. x 8 in. in size shall be provided from the top of the air space to a ventilator or hatchway. Sheathing shall be supported on vertical runners spaced not less than 2 ft. apart centre to centre and shall consist of 2 in. planks or two thicknesses of 1 in. boards laid to break joint. | ||||||||||||||||||||||||||||||||

STOWAGE. | ||||||||||||||||||||||||||||||||

Holds, Compartments or Bins Partly Filled with Loose Grain in Bulk. | ||||||||||||||||||||||||||||||||

24. If any hold, compartment or bin is partly filled with loose grain in bulk, the grain shall be levelled and topped off with bagged grain or other suitable cargo extending to a height not less that 4 ft. above the top of the loose grain in bulk and supported on suitable platforms laid over the whole surface of the loose grain in bulk. In addition the hold or compartment, as the case may be, shall be divided by a properly constructed longitudinal bulkhead or by shifting boards which shall be in line with the keel, and shall extend from the bottom of the hold or deck, as the case may be, to a height of not less than 2 ft. above the surface of the bulk grain in such a way as to prevent shifting. | ||||||||||||||||||||||||||||||||

Provided that the fitting of a longitudinal bulkhead or shifting boards in a lower hold shall not be required if the grain in bulk does not exceed one-third of the capacity of the hold, or in the case of a hold containing a shaft or other similar tunnel, one-half the capacity of the hold. | ||||||||||||||||||||||||||||||||

Holds, Compartments or Bins Entirely Filled with Loose Grain in Bulk. | ||||||||||||||||||||||||||||||||

25. If any hold or compartment is entirely filled with loose grain in bulk, it shall be divided by a longitudinal bulkhead or shifting boards, in line with the keel, which shall be properly constructed and secured, and fitted grain-tight with proper fillings between the beams. In holds such shifting boards shall extend downwards from the underside of the deck to a distance of at least one-third of the depth of the hold or 8 ft. whichever is the greater. In compartments in 'tween decks and superstructures they shall extend from deck to deck. In all cases the shifting boards shall extend to the top of the feeders of the hold or compartment in which they are situated. | ||||||||||||||||||||||||||||||||

26. All bulk grain shall be well trimmed up between the beams and in the wings and the space between them shall be completely filled. | ||||||||||||||||||||||||||||||||

27. Any hold, compartment or bin which is entirely filled with loose grain in bulk shall be fed by suitably placed and properly constructed feeders, which shall contain not less than 2½ per cent. or more than 8 per cent. of the quantity of grain carried in the compartment that they feed. When loose grain in bulk is loaded in a deep tank, specially built feeders shall not be required if the deep tank is divided by a steel centre longitudinal division and the bulk grain is well stowed, the tank and tank hatchways being completely filled and the hatch covers secured. | ||||||||||||||||||||||||||||||||

28. Feeders to a hold, compartment or bin shall be so arranged as to secure a free flow of grain to all parts of that hold, compartment or bin. When the distance, measured in a fore and aft line, from any part of a hold or compartment to the nearest feeder exceeds 25 ft. the grain in the end spaces beyond 25 ft. from the nearest feeder shall be levelled off at a depth of at least 6 ft. below the deck, and the end spaces filled with bagged grain built up on a proper platform. | ||||||||||||||||||||||||||||||||

29. The platforms required by this Schedule shall consist of bearers spaced not more than 4 ft. apart and 1 in. boards aid thereon spaced not more than 4 in. apart or tarpaulins or strong separation cloths with adequate overlapping. | ||||||||||||||||||||||||||||||||

30. Light grain in bulk shall be carried in the case of a single deck ship in the holds or superstructures thereof and in the case of other ships only in the holds or 'tween decks thereof and in all cases feeders and shifting boards shall be fitted which comply with this Schedule. In ships where 'tween decks or shelter decks are not subdivided, bulkheads shall be constructed so as to divide such shelter decks or 'tween decks, as the case may be, into compartments of a maximum length of not exceeding 70 ft. | ||||||||||||||||||||||||||||||||

31. Heavy grain in bulk shall not be carried above deck except in the manner specified in paragraphs 32 and 33 of this Schedule. | ||||||||||||||||||||||||||||||||

32. Heavy grain in bulk shall not be carried above deck in a single deck ship, or in the 'tween deck of a two deck ship, or in the uppermost 'tween deck of a ship having more than two decks except :— | ||||||||||||||||||||||||||||||||

(a) in feeders properly constructed in accordance with this Schedule ; | ||||||||||||||||||||||||||||||||

(b) in bins properly constructed in accordance with this Schedule. | ||||||||||||||||||||||||||||||||

33. Where heavy grain in bulk is carried in bins :— | ||||||||||||||||||||||||||||||||

(i) the compartment or compartments immediately below the bins shall be completely filled with bulk grain ; | ||||||||||||||||||||||||||||||||

(ii) the hold or compartment below the bin or bins shall be properly battened down clear of the feeder to such hold or compartment : | ||||||||||||||||||||||||||||||||

(iii) the aggregate quantity of grain carried in bins and all feeders shall not exceed 23 per cent. by weight of the total cargo below the deck on which the bins are situated ; | ||||||||||||||||||||||||||||||||

(iv) the capacity of any bin shall not exceed 8,000 cu. ft ; | ||||||||||||||||||||||||||||||||

(v) where the distance from the feeder to the transverse bulkhead exceeds 20 ft. the space beyond shall be filled with bagged grain or other suitable cargo ; | ||||||||||||||||||||||||||||||||

(vi) where a bin is not completely filled with grain the provisions of paragraph 24 of this Schedule shall apply. | ||||||||||||||||||||||||||||||||

34. Shifting boards shall not be required to be fitted in holds, 'tween decks or superstructures being holds, 'tween decks or superstructures which contain only grain in bags. | ||||||||||||||||||||||||||||||||

35. Bagged grain shall be carried in sound bags which shall be well filled and securely closed. | ||||||||||||||||||||||||||||||||

LOADING OF GRAIN ON HOME-TRADE SHIPS. | ||||||||||||||||||||||||||||||||

36. The foregoing requirements of this Schedule shall not apply to any home-trade ship on which grain is loaded if such precautions as are specified in paragraphs 37 and 38 of this Schedule are taken to prevent the grain from shifting. Provided that the provisions of paragraphs 32 and 33 of this Schedule shall apply to any two-deck ship loaded with heavy grain in bulk in the 'tween deck and to any ship, having more than two decks, loaded with heavy grain in bulk in the uppermost 'tween deck. | ||||||||||||||||||||||||||||||||

Holds, Compartments or Bins Entirely Filled with Loose Grain in Bulk. | ||||||||||||||||||||||||||||||||

37. If any hold, compartment or bin in a home-trade ship is entirely filled with loose grain, the grain shall be trimmed tightly into the wings, ends and beam spaces. The hatchway shall also be filled in such a way that it shall act as a feeder in the event of the grain settling during the voyage. The hatchway shall contain not less than 4 per cent. by weight of the grain carried in the hold below deck level. | ||||||||||||||||||||||||||||||||

Holds, Compartments or Bins Partly Filled with Loose Grain in Bulk. | ||||||||||||||||||||||||||||||||

38.—(1) If any hold, compartment or bin in a home-trade ship is partly filled with loose grain, the grain shall be stowed in the manner specified in paragraph 24 of this Schedule. Provided that, in such a ship, not more than two holds or compartments may be stowed in the manner specified in sub-paragraph (2) or sub-paragraph (3) of this paragraph. | ||||||||||||||||||||||||||||||||

(2) The grain shall be levelled off and overstowed with at least two tiers of bagged grain laid on separation cloths, or with other suitable cargo supported on platforms or separation cloths. | ||||||||||||||||||||||||||||||||

(3) (a) The grain shall be divided from the empty space in the hold by one of the following methods :— | ||||||||||||||||||||||||||||||||

Method 1. A transverse vertical wooden bulkhead shall be fitted in the fore part of the hold in such a way as to reduce the capacity of the hold to that required for the stowage of the grain. The bulkhead shall be of adequate strength to withstand the pressure of the grain in all circumstances. | ||||||||||||||||||||||||||||||||

Method 2. A strongly and tightly constructed transverse vertical bulkhead of bagged grain shall be used. The bulkhead shall contain sufficient rows of bags laid in a fore and aft direction to enable it to withstand the effects of pitching and scending during the voyage. Its foundation shall be on the floor of the hold and shall consist of not less than four rows of bags. | ||||||||||||||||||||||||||||||||

Method 3. A sloping bulkhead shall be constructed of stepped bags of grain. The bags shall be packed tightly together and bedded into the grain in a fore and aft direction. They shall lie horizontally, and overlap not less than one-half of their length. The lowest tier shall be arranged so as to rest upon a firm and solid foundation, and shall be placed on the floor of the hold or on separation cloths laid on a levelled grain surface reaching to one of the ship's transverse bulkheads. The bags shall be well locked into the frames at the ship's side and a double tier shall be laid at the sides of the holds. The bulkhead shall be secured in the hatchway and the top tier of bags shall be so wedged tightly against the web beams or the hatch end coamings that they will be secured against fore and aft movement. | ||||||||||||||||||||||||||||||||

(b) The grain shall be stowed in such a way as to confine its loose surface within the limits of the hatchway in such a manner that it will serve as a feeder. The part of the hold containing grain shall be completely filled and the grain shall be so confined as to prevent any of it getting in to the empty part of the hold. It shall be trimmed tightly into one end of the hold, the wings, end and beam spaces shall be filled, and as much grain as possible shall be stowed at the same end of the hatchway so as to ensure a sufficient supply for feeding purposes. | ||||||||||||||||||||||||||||||||

(c) The bags referred to in this sub-paragraph shall be in sound condition. They shall be loosely filled and securely closed, and the mouths of the bags shall always be laid towards the bulk grain. | ||||||||||||||||||||||||||||||||

GIVEN under my official Seal, this 12th day of November, 1953. | ||||||||||||||||||||||||||||||||

SEAN F. LEMASS, | ||||||||||||||||||||||||||||||||

Minister for Industry and Commerce. | ||||||||||||||||||||||||||||||||