S.I. No. 355/1949 - Standard Specification (Water Paints and Distempers For Interior Use) Order, 1949.

S.I. No. 355 of 1949. | ||

STANDARD SPECIFICATION (WATER PAINTS AND DISTEMPERS FOR INTERIOR USE) ORDER, 1949. | ||

I, DANIEL MORRISSEY, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946), hereby order as follows :— 1. This Order may be cited as the Standard Specification (Water Paints and Distempers for Interior Use) Order, 1949. 2.—(1) The specification set forth in Part II of the Schedule to this Order is hereby declared to be the standard specification for the commodity described in Part I of the said Schedule. | ||

(2) The said standard specification may be cited as Irish Standard 22 : 1949. | ||

|

SCHEDULE. | ||

PART I. | ||

WATER PAINTS AND DISTEMPERS FOR INTERIOR USE. | ||

PART II. | ||

SPECIFICATION | ||

In this specification, the letters I.S., when followed by two sets of numbers, refer to the Irish Standard of which the first is the serial number and the second the year of its promulgation by the Minister for Industry and Commerce. | ||

In this specification, the letters B.S., when followed by two sets of numbers, refer to the British Standard of which the first is the serial number and the second is the year of its publication by the British Standards Institution. | ||

SCOPE | ||

1. This specification applies to water paints and distempers for interior use, and covers the following types :— | ||

(a) Water Paint, washable, paste, oil-bound, water paints, including pigmented oil-in-water emulsions of drying-oil, varnish, or other similar and suitable materials. | ||

(b) Distemper—Type 1, washable, paste or powder, oil-free, pigmented compositions, based on casein alkaline silicates or cements, or other similar and suitable materials. | ||

(c) Distemper—Type 2, non-washable, paste or powder, oil-free, pigmented compositions, based on glue, starch or other similar and suitable materials. | ||

CONSISTENCY | ||

2. The water paint or distemper when supplied shall be of a consistency such that it may be made ready for use by thinning with water or petrifying liquid only. | ||

DIRECTIONS FOR USE | ||

3. The nature and quantity of the thinner, the method of application of the water paint or distemper, and the approximate covering capacity shall be stated on the container. | ||

HIDING POWER | ||

4. When prepared and applied to a test chart in accordance with the directions on the container and in the manner described in Appendix A, the material shall give obscuration of the surface pattern of the test chart not inferior to that given by an agreed sample when similarly applied. | ||

COLOUR AND FINISH | ||

5. The material, when thinned and applied evenly to a smooth moderately absorbent surface, such as cartridge paper, shall yield when dry, a uniform film which in colour and finish matches closely either (a) a film prepared in the same way and at the same time from an agreed sample, or (b) such other standard of colour and finish as may be agreed to by the purchaser and the vendor. | ||

VOLATILITY | ||

6. The volatility of the material, when determined in the manner described in Appendix B, shall be not greater than 30 per cent. for material supplied in the form of paste or emulsion, and not greater than 5 per cent. for material supplied in powder form. | ||

OIL OR OIL VARNISH CONTENT OF WATER PAINT. | ||

7. The oil or oil varnish content of water paint, when determined by the method described in Appendix C, shall be not less than 5 per cent. | ||

WHITE PIGMENT | ||

8. White pigment in water paint or distemper shall be lithopone, or zinc ox de type 1, or titanium white types 1 to 4 inclusive, and shall conform to the requirements for the appropriate material, of I.S. 21 : 1949. | ||

The residue left from a dry film of water paint after the extraction of the oil or oil varnish by the method described in Appendix C, shall yield on analysis not less than 45 per cent. of lithopone, or not less than 45 per cent. of zinc oxide, or not less than 12·5 per cent. of titanium dioxide (TiO2) in the form of titanium white types 1 to 4 inclusive.. | ||

COARSE PARTICLES | ||

9. The coarse particles present in the material, when determined by the method described in Appendix D, shall be not more than 1 per cent. | ||

BRIGHTNESS | ||

10. A single coat of white water paint, when tested by a method such as that described in Appendix E, shall have a brightness of not less than 85 per cent. of that of a surface of smoked magnesium oxide. | ||

A single coat of distemper when similarly tested shall have a brightness of not less than 80 per cent. of that of a surface of smoked magnesium oxide. | ||

RESISTANCE TO DRY RUBBING | ||

11. The material shall be applied, as stated on the container, to a metal sheet lightly sandpapered and allowed to dry at ordinary room temperature (about 16°C.) and at a relative humidity not exceeding 80 per cent. Thirty minutes after the water in the film has evaporated as judged visually, the film shall be rubbed with the finger briskly and with the use of as much pressure as is comfortable. No appreciable amount of the film shall come off on the finger. | ||

Alternatively, the material, when tested in the manner described above, shall not be inferior to an agreed sample tested similarly and at the same time. | ||

RE-COATING — WATER PAINT AND DISTEMPER, TYPE 1. | ||

12. The water paint or distemper type 1, shall withstand re-coating when tested in the manner described in Appendix F. | ||

KEEPING PROPERTIES | ||

13. When stored in the original sealed container under conditions agreed to by the purchaser and vendor the material shall retain the properties specified in the preceding clauses for such a period, of not less than 12 months, as shall be agreed to by the purchaser and the vendor. | ||

SAMPLING AND SIZE OF SAMPLE | ||

14. Representative samples, each weighing not less than one pound, shall be taken in triplicate from one or more original and previously unopened containers, or from the bulk during filling. They shall be packed in clean dry air-tight non-absorbent containers made of material on which the sample has no action. The containers shall be of a size such that they are nearly filled by the sample. Each container so filled shall be sealed and shall be marked with the date of sampling, and with sufficient information to identify the sample. | ||

AGREED SAMPLE | ||

15. Except where otherwise agreed between purchaser and vendor, the agreed sample referred to in this specification shall be one and the same sample and shall comply in all respects with the requirements of this specification. It shall weigh not less than one pound and shall be packed in the manner described in Clause 14. | ||

APPENDIX A | ||

Method for the Determination of Hiding Power | ||

The test shall be carried out on a hiding power chart, 1 sq. ft. in area, having a semi-absorbent surface and provided with a black and white or grey and white checker board design. | ||

Sufficient material to cover an area of 1 sq. foot, in accordance with the covering capacity stated on the container, shall be weighed out to the nearest 0·1 g. The material shall be applied by brushing to the chart in accordance with the method stated on the container and allowed to dry. The chart shall be viewed in diffused daylight in a direction normal to the surface. | ||

APPENDIX B | ||

Method for the Determination of Volatility | ||

A quantity of between 1·0 g. and 2·0 g. of the material shall be weighed in a flat-bottomed, circular metal or glass dish about 7·5 cm. in diameter, and the dish heated at 100°C. to 105°C. in a suitable oven for three hours. The dish and contents shall then be allowed to cool to air temperature in a desiccator and weighed. The loss in weight, calculated as a percentage of the original weight, shall be the volatility of the material. | ||

APPENDIX C | ||

Method for the Determination of the Oil or Oil Varnish Content of Water Paint | ||

The water paint shall be applied to a clean glass plate, of an area not less than 900 sq. cm., by the method described on the container. The plate shall be allowed to stand for thirty minutes after the water paint has become dry as judged visually. The dry paint film shall be removed by means of a scraper and ground lightly in a mortar. A quantity, estimated to yield between 0·25 g. and 0·5 g. oil or oil varnish, shall be transferred to a Soxhlet apparatus and extracted completely with methylated ether. The bulk of the ether shall be removed from the extract by distillation and the remainder removed over a hot plate. The weight of the extract shall be determined and this result calculated as a percentage of the weight of the paint film taken, shall be taken as the oil or oil varnish content of the water paint. | ||

APPENDIX D | ||

Method for the Determination of Coarse Particles | ||

100 g. of the material shall be made into a thin cream by the addition of water and transferred to a No. 200 British Standard test sieve complying with B.S. 410 : 1943, or to a test sieve of equivalent fineness, which has been previously dried and weighed. The residue remainingon the sieve shall then be washed with water and gently brushed with a soft camel-hair pencil until the washings are clear, taking care to press out particles of gel, which might otherwise be resistant to the washing process. The washing water may be warm but shall not be under pressure. The final residue shall be dried in a suitable oven at 100° C. to 105° C. for one hour, allowed to cool and weighed. This result shall be the percentage of coarse particles present in the material. | ||

APPENDIX E | ||

Method for the Determination of Brightness | ||

A parallel beam of white light shall be allowed to impinge at an angle of 45° on a panel to which a coat of the material to be tested has been applied and the light reflected normally from the surface shall be measured by means of a light-sensitive cell and a galvanometer In the same way the light reflected from a panel smoked with a thick layer of magnesium oxide shall be measured and the results compared. | ||

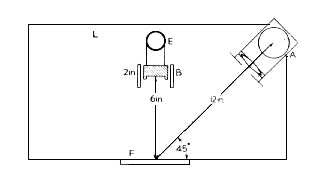

A suitable form of apparatus is shown diagrammatically in Fig. 1. | ||

A. is a 100 watt projection lamp, collimating lens and adjustable diaphragm assembly to give the parallel beam of light, and having the diaphragm adjusted so that the area illuminated shall be not larger than the area of the panel F. The light source shall be furnished with a heat absorbing glass filter as described in Appendix E of B.S. 1053 : 1942, and in addition an Ilford gamma filter. | ||

B. is a light-sensitive cell. | ||

E. is a galvanometer of sensitivity suitable for the cell employed. | ||

F. is the panel, 2 in. square, the brightness of which is to be measured. | ||

L. is a light-tight box in which the apparatus is assembled. The interior of the box shall be painted dead black, or lined with black velvet. | ||

APPENDIX F | ||

Method for the Determination of Resistance to Re-Coating | ||

A single coat of the material to be tested shall be applied in accordance with the directions on the container to a lightly sandpapered metal sheet of an area about 1 ft. square. After about twenty-four hours drying at about 16° C. and at a relative humidity not exceeding 80 per cent., a second coat shall be applied, holding the sheet in the hand by one corner and ensuring an evenly spread film by laying off length-wise and cross-wise, twice in each direction. The film shall then be subjected immediately to a jet of cold water blown from a wash-bottle held so that the jet is 6 in. long. If the second coat, while still wet, is removable in this way from the first without exposing any of the metal sheet, the material tested is resistant to re-coating. | ||

GIVEN under my Official Seal, this 23rd day of December, 1949. | ||

DANIEL MORRISSEY, | ||

Minister for Industry and Commerce. | ||

| ||

Fig. 1. |