S.I. No. 351/1952 - Standard Specification (Irish Handwoven Tweed) Order, 1952.

S.I. No. 351 of 1952. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

STANDARD SPECIFICATION (IRISH HANDWOVEN TWEED) ORDER, 1952. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

I, SEÁN F. LEMASS, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946), hereby order as follows:— 1. This Order may be cited as the Standard Specification (Irish Handwoven Tweed) Order, 1952. 2.—(1) The specification set forth in Part II of the Schedule to this Order is hereby declared to be the standard specification for the commodity described in Part I of the said Schedule. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The said standard specification may be cited as Irish Standard 30: 1952. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SCHEDULE. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART I. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IRISH HANDWOVEN TWEED. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART II. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SPECIFICATION. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DEFINITIONS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. For the purposes of this specification the following definitions shall apply:— | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) Irish Handwoven Tweed: Cloth made from yarn, spun in a mill or factory and woven on a hand-loom in Ireland. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Irish Woollen Count: A measure of the length per unit weight of the yarn expressed as the number of yards of yarn per quarter ounce. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

COMPOSITION OF CLOTH. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2. Irish handwoven tweed shall be made exclusively from virgin wool free from waste, shoddy or impurities. It shall be clean scoured after weaving and shall contain not more than 0·1 per cent. vegetable impurities, not more than 0·5 per cent. residual oil, and not more than 0·5 per cent. residual soap. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

When tested as described in Appendix A the percentage loss in weight shall not exceed 1·5. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

COLOUR FASTNESS TO LIGHT. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3. Irish handwoven tweed shall show no appreciable change in colour when tested for 40 hours according to the method described in Appendix B. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MANUFACTURE OF CLOTH. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4. Irish handwoven tweed shall be woven plain or twill and shall be one of the types set out in the Weaving Schedule. The count of the yarn and the warp and weft settings for each type of cloth shall be as set out in the Weaving Schedule. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

WEAVING SCHEDULE. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

WIDTH. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5. The finished cloth shall be of uniform width of not less than 28 inches measured between the distinctively coloured list yarns when such are present and, in their absence, between the selvedges. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SHRINKING. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6. The cloth shall be shrunk. The shrinkage on wetting when determined in the manner described in Appendix C shall not exceed 2 per cent. either in the warp or in the weft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MARKING. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7. Irish handwoven tweed conforming to this specification shall be marked with the words: " Láamh-fhite arna dhéanamh i............ Éire " (" Handwoven made at............... Ireland ") the district in which the cloth is made being inserted. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Appendix A. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DETERMINATION OF PERCENTAGE LOSS IN WEIGHT. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

A sample of cloth weighing about 2 g. shall be dried to constant weight in an oven at 105°C. to 110°C. and then weighed carefully to obtain the oven-dry weight " W." The sample shall be immersed for 7 to 10 minutes in 200 ml. of a boiling solution of 1 per cent. sulphuric acid. The sample shall be transferred to a Buchner or Hirsch funnel of 45 mm. diameter disc and the excess acid solution removed by suction. The sample shall be allowed to cool and then shall be held over a 400 ml. beaker and carefully cut into strips. approximately 11/8 in. wide. One hundred and sixty ml. of sulphuric acid of concentration 70 (±1) per cent. by weight at 38°C. shall then be added. The exact concentration of the sulphuric acid solution shall be determined by titration. The liquid shall be stirred frequently, and after 15 minutes the mixture of the acid solution and fibres shall be poured cautiously but quickly into 600 ml. of cold water in a one-litre beaker. The 400 ml. beaker shall be rinsed with two 50 ml. portions of water and the washings added to the one-litre beaker. The fibres shall be filtered from the solution by suction using a tared crucible with a sintered glass bottom. The fibres shall be rinsed with several portions of cold water, dried by suction, and then 200 ml. of a cold aqueous solution (2 per cent.) of sodium bicarbonate shall be added and the rate of filtering reduced so that the sodium bicarbonlate solution comes in contact with the fibres for not less than 5 minutes. The fibres shall be rinsed again with several portions of cold water and dried by suction. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The fibres shall be dried at 105°C. to 110°C. to constant weight, " D." | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

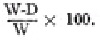

The percentage loss in weight shall be taken as | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Appendix B. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DETERMINATION OF COLOUR FASTNESS TO LIGHT. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Apparatus. The apparatus for this test shall be a suitable fading lamp consisting of a carbon arc enclosed in heat resistant glass. The glass shall be thoroughly cleaned every 24 hours of use. The lamp shall be operated on a direct current of approximately 12 to 14 amp. or 50-cycle alternating current of approximately 15 to 17 amp. with 140 volts across the arc, the voltage of the power line to the apparatus being 200 to 250 volts. The distance from the arc to the test specimen shall be 10 in. and the specimen shall rotate about the arc to ensure uniformity of exposure. The air about the specimen during exposure shall be humidified and its temperature shall be automatically controlled between 38°C. and 46°C. The relative humidity of the air in the apparatus filled with specimens and operating for a sufficient period of time to reach temperature equilibrium shall not exceed 80 per cent. measured by wet and dry bulb thermometer shielded from the radiation of the arc. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Test Specimens. Specimens measuring 2½ in. by 3 in. shall be cut from the cloth to be tested, in such a way that the longer dimensions shall be parallel to the warp direction. They shall be taken in such a way that all of the colours of the cloth are included. If a specimen does not include all of the colours in the design, additional specimens shall be prepared so that each of the colours of the cloth shall be included in the tests. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Procedure. Each specimen shall be placed between opaque covers that will shield it from light, except for an area of about 15/8 in. x 2 in. which shall be open to the air on both sides. The specimen so protected shall be exposed in the apparatus described above for the prescribed period. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Evaluation. After exposure the specimens shall be allowed to lie in the dark at room temperature for at least two hours before examination. Comparison shall then be made between the exposed and unexposed parts of specimens. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX C. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DETERMINATION OF SHRINKAGE. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Samples for shrinkage test, measuring 20 in. by 20 in., shall be taken. These shall be laid flat for 2 hours in cold water and dried on a flat surface at a temperature between 16°C. and 20°C. Test pieces shall be measured under plate glass, before and after shrinkage. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GIVEN under my Official Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

this 1st day of December, 1952. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(Signed) SEÁN F. LEMASS, | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Minister for Industry and Commerce. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||