S.I. No. 321/1951 - Standard Specification (Zinc Chromate Primers For Use on Aluminium and Light Alloys) Order, 1951.

S.I. No. 321 of 1951. | ||

STANDARD SPECIFICATION (ZINC CHROMATE PRIMERS FOR USE ON ALUMINIUM AND LIGHT ALLOYS) ORDER, 1951. | ||

I, SEAN F. LEMASS, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946), hereby order as follows :— 1. This Order may be cited as the Standard Specification (Zinc Chromate Primers for use on Aluminium and Light Alloys) Order, 1951. 2.—(1) The specification set forth in Part II of the Schedule to this Order is hereby declared to be the standard specification for the commodity described in Part I of the said Schedule. | ||

(2) The said standard specification may be cited as Irish Standard 33 : 1951. | ||

|

SCHEDULE. | ||

PART I. | ||

ZINC CHROMATE PRIMERS FOR USE ON ALUMINIUM AND LIGHT ALLOYS. | ||

PART II. | ||

SPECIFICATION. | ||

In this specification, the letters I.S., when followed by two sets of numbers, refer to the Irish Standard of which the first is the serial number and the second the year of its promulgation by the Minister for Industry and Commerce. | ||

In this specification, the letters B.S., when followed by two sets of numbers, refer to the British Standard of which the first is the serial number and the second is the year of its publication by the British Standards Institution. | ||

SCOPE. | ||

1. This specification covers the requirements for zinc chromate primers for use on aluminium and light alloys. | ||

CONSISTENCY. | ||

2. The consistency of the paint when determined in the manner described in Appendix B shall be from 220 to 340. | ||

COVERING POWER. | ||

3. The covering power when determined in the manner described in Appendix C shall be not less than 70 sq. yd. per gallon. | ||

DRYING TIME. | ||

4. The paint when tested in accordance with the method described in Appendix D shall become " surface dry " in not less than 6 hours and shall become " hard dry in " not more than 24 hours. | ||

For the purpose of this clause the term " surface dry " shall mean a condition such that clean dry silver sand sprinkled on to the surface of the paint film and kept there for one minute, can be removed by means of a camel-hair brush without injury to the paint film. The sand used shall be graded so as to pass a No. 52 test sieve conforming to I.S. 24 : 1950 but to be retained on a No. 100 test sieve conforming to I.S. 24 : 1950. | ||

For the purpose of this clause the term " hard dry " shall mean a condition such that after a slight rubbing down a second coat of the paint can be satisfactorily applied. | ||

FLEXIBILITY. | ||

5. The dried paint film when tested in the manner described in Appendix E shall not show cracking, peeling, crazing or flaking | ||

RESISTANCE TO WATER. | ||

6. The dried paint film when tested in the manner described in Appendix F shall neither soften nor show any visible defect other than a slight change in colour. | ||

VOLATILE CONTENT. | ||

7. The volatile content of the paint when determined as described in Appendix G shall not exceed 35 per cent. | ||

COMPOSITION. | ||

8. The paint shall contain not less than 30 per cent. of zinc chrome conforming to B.S. 389 : 1938, calculated on the total solid content of the paint. Compounds of the heavy metals other than zinc and chromium shall not exceed a total of 0.5 per cent. calculated as metals. | ||

WATER CONTENT. | ||

9. The water content of the paint when tested in the manner described in Appendix H shall be not more than 0·5 per cent. | ||

SKINS AND COARSE PARTICLES. | ||

10. The paint when tested in the manner described in Appendix J shall pass through a No. 80 test sieve conforming to I.S. 24 : 1950 leaving no residue of skins or coarse particles. | ||

FLASH POINT. | ||

11. The flash point of the paint, when determined by Abel's closed test, shall be not below 78° F. | ||

MARKING. | ||

12. The containers of paint shall be marked distinctly with the manufacturer's name or mark, the date of manufacture and the net volume of the contents. | ||

SAMPLING AND SIZE OF SAMPLES. | ||

13. For the purpose of testing conformity with the requirements of this specification representative samples measuring not less than 1 pint shall be taken in triplicate from one or more original and previously unopened containers, or from the bulk during filling. The samples shall be packed in clean dry air-tight non-absorbent containers made of material on which the paint has no action. The containers shall be of a size such that they are nearly filled by the sample. Each container so filled shall be sealed and shall be marked with the date of sampling, and with sufficient information to identify the sample. | ||

Appendix A. | ||

METHOD FOR THE PREPARATION OF TEST PANELS. | ||

(a) Test Panel. The test panels used for testing conformity of paints to this specification shall be 6 in. by 3 in. in area and shall consist of either low carbon sheet steel of 0·036 in. thickness or bright tin-plate of 0·0124 in. thickness. | ||

Sheet steel panels shall be degreased by a suitable solvent such as acetone, benzene, or a low boiling petroleum spirit, and after evaporation of the solvent they shall be immersed for 2 to 3 minutes in a 5 per cent. solution of orthophosphoric acid (H3PO4) containing a few drops of wetting agent. After immersion the panels shall be rinsed in distilled water and dried in an oven at a temperature of 100° C. to 105° C. | ||

Tin-plate panels shall be cleaned by a degreasing solvent and dried in an oven at a temperature of 100° C. to 105° C. | ||

Panels prepared as described above shall be wrapped in clean paper and kept in a desiccator. They shall be handled with tongs or forceps. | ||

(b) Application of Paint to Test Panel. Using the value of the covering power of the paint determined as described in Appendix C the weight of paint to be applied to the test panel shall be calculated for the area of the panel. | ||

A test panel shall be weighed and placed in a horizontal position. The paint shall be well mixed and shall be brushed out on the panel so as to produce a uniform film and, by means of a brush, paint shall be added to or removed from the panel until the weight of the paint film as determined by rapid trial weighings is that calculated. The painted panel shall be allowed to dry in a vertical position in a substantially dust-free atmosphere at a temperature of 15° C. to 20°C. and for the period of time required for the test concerned. | ||

Appendix B. | ||

METHOD FOR THE DETERMINATION OF CONSISTENCY. | ||

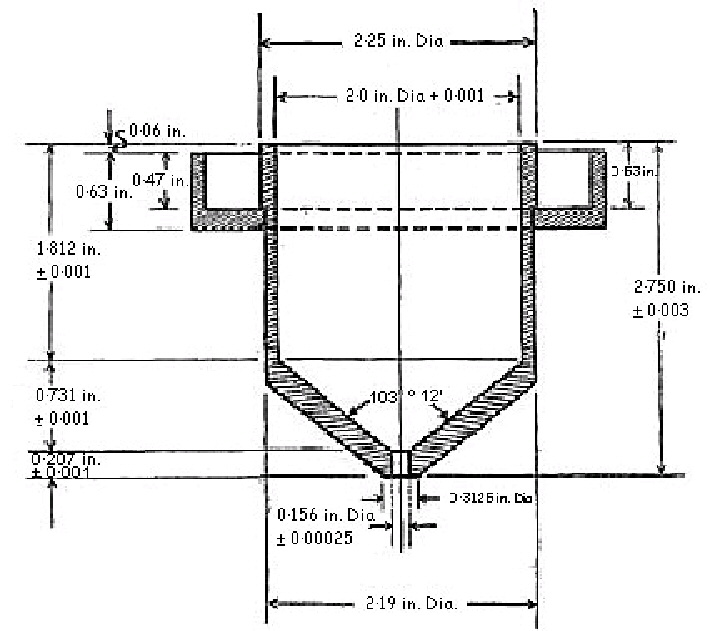

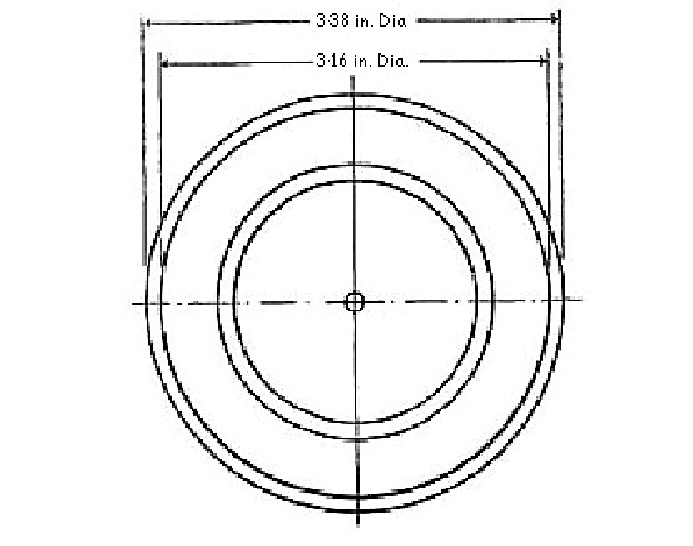

The apparatus used for this test shall be the Ford Cup No. 4 and shall be of the construction and dimensions given in Figure 1. | ||

The protecting sleeve shall be removed from the apparatus and the cup with its stand placed in an air-bath maintained at a temperature of 22° C.±0·5° C. for 60 minutes. The sample to be tested shall then be allowed to remain in the same air-bath until its temperature reaches 22° C.±0·5° C. A biological water-jacketed incubator forms a suitable air-bath. | ||

The apparatus shall be removed from the air-bath and levelled on its stand by means of a spirit level placed on the rim. The orifice shall be closed with one finger and the sample shall be poured into the cup until it overflows into the gallery, care being taken to reduce the formation of air-bubbles to the minimum. The surface of the paint shall be freed from bubbles if necessary and a straight edge shall be slowly drawn across the rim of the cup so that excess paint flows into the gallery. The finger shall be removed from the orifice and a stopwatch simultaneously started. The time of efflux in seconds shall be determined by stopping the stop-watch at the instant the issuing stream breaks up into drops. | ||

During the course of a determination the apparatus shall be screened from air draughts. | ||

The mean of three observations shall be taken as a measure of the consistency but any observation deviating from the mean by more than 1 per cent. shall be rejected and an additional determination carried out. | ||

The time of efflux in seconds shall be taken as the consistency of the paint. | ||

Appendix C. | ||

METHOD FOR THE DETERMINATION OF COVERING POWER OF UNDERCOATING PAINT. | ||

The covering power shall be determined using an opacity chart with an oil-proof surface which contains geometrical designs of adjacent black and white areas, or black and grey areas. For squared charts the length of the sides of the squares shall not exceed 5 cm. and for other types of charts such as figured charts the thickness of the black, grey or white lines shall not exceed 1·5 cm. The reflectivity of the areas, as tested by the gloss meter described in Appendix G shall be, for white 75 per cent, for grey 25 per cent. and for black 2 per cent., of that of a surface of freshly smoked magensium oxide. The area of the opacity chart shall be not less than 1 sq. ft. | ||

The weight per gallon of the paint shall be determined. The opacity chart shall be weighed to the nearest 0·1 g. and the paint shall be brushed on evenly and spread over its area. Paint shall be added to or removed from the surface with further light brushing until no difference in brightness between the adjacent areas of the chart isdiscernible. The chart shall then be weighed and shall be allowed to dry in a vertical position in a substantially dust-free atmosphere for a period of 24 hours at a temperature of 15° C. to 20° C. It shall then be placed in a vertical position and viewed at a distance of 6 to 9 feet. If a difference in brightness between the adjacent areas of the chart is discernible, the whole test shall be repeated using additional paint until obscuration in the dry state is obtained. From the weight of paint used the covering power in square yards per gallon shall be calculated. | ||

Appendix D. | ||

METHOD FOR THE DETERMINATION OF DRYING TIME. | ||

The paint shall be applied to a test panel as described in Appendix A and the panel shall be placed in a vertical position in a well-ventilated room so as to expose the paint film to diffused daylight for at least 6 hours during the drying period. During the drying period the temperature of the room shall be between 15° C. and 20° C. and shall be above the dew point. The painted panel shall be tested for surface dryness after 6 hours and for hard dryness after 24 hours. | ||

Appendix E. | ||

METHOD FOR TESTING FLEXIBILITY. | ||

A test panel shall be prepared as described in Appendix A and shall be allowed to dry for 24 hours. The test panel with the painted surface uppermost shall be placed over a ¼ in. mandrel and bent rapidly through 180°. It shall then be examined visually. The time of bending shall be not less than one second and not more than 1·5 seconds. The test shall be carried out at room temperature. | ||

Appendix F. | ||

METHOD FOR THE DETERMINATION OF RESISTANCE TO WATER. | ||

A test panel with the paint applied to it, shall be prepared as described in Appendix A and allowed to dry for 72 hours. The panel shall be placed vertically in distilled water so that it is immersed to a depth of 3 inches. The temperature of the water shall be 15° C. to 20° C. and the panel shall be kept immersed for a period of 16 hours. The test panel shall then be withdrawn, shaken to remove surface water, and be allowed to dry in a dust-free atmosphere at a temperature of 15° C. to 20° C. The test panel shall then be examined visually. | ||

Appendix G. | ||

METHOD FOR THE DETERMINATION OF VOLATILE CONTENT. | ||

One to 2 g. of the paint shall be weighed into a flat-bottomed circular dish about 3 in. diameter and 1 in. internal depth and heated for 3 hours in a suitable oven at 105° C. to 110° C. The dish shall then be allowed to cool to air temperature and re-weighed. The percentage loss in weight shall be regarded as the volatile content. | ||

Appendix H. | ||

METHOD FOR THE DETERMINATION OF WATER CONTENT. | ||

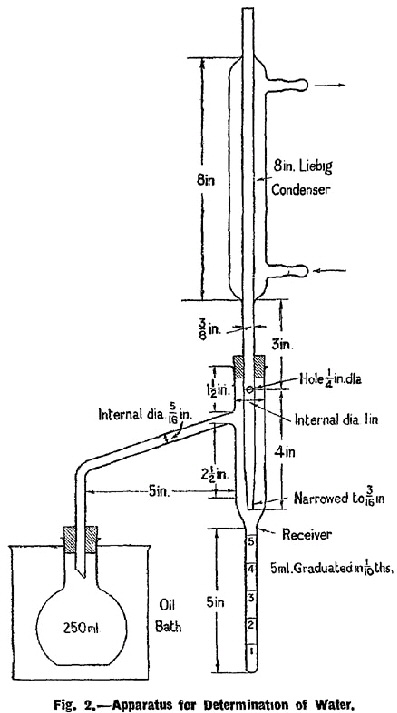

The apparatus shown in Figure 2 shall be used for the determination of the water content. One hundred g. of the paint shall be weighed in the flask and 100 ml. of petroleum spirit, boiling between 75° C. and 85° C., and 1 ml. of dry amyl or ethyl acetate shall be added, and the contents of the flask then well mixed. Petroleum spirit shall be poured into the receiver up to the level of the side tube. The flask shall be connected to the apparatus and shall be immersed in an oil bath containing sufficient heavy mineral oil to cover it to the neck. The flask shall be heated to a temperature such as will keep its contents boiling briskly. Distillation shall be continued until no further water collects in the receiver. At the end of the distillation any water still clinging to the condenser tube shall be released and caused to fall into the receiver by pushing a wire, or a small camel-hair brush attached to a glass rod, through the condenser tube from the top and any condensed water on the sides of the receiver shall be dislodged after dismantling the upper part of the apparatus. The volume of water in the receiver shall be noted and its weight calculated as a percentage of the original weight of the paint. | ||

Appendix J. | ||

METHOD FOR THE DETERMINATION OF FREEDOM FROM SKINS AND COARSE PARTICLES | ||

The paint sample shall be well mixed and 20 g. of the paint shall be poured through a No. 80 test sieve conforming to I.S. 24 : 1950. Any residue remaining on the sieve shall be washed with white spirit, not under pressure, and gently brushed with a soft camel-hair brush. | ||

GIVEN under my Official Seal this 5th day of November, 1951. | ||

SEAN F. LEMASS, | ||

Minister for Industry and Commerce. | ||

| ||

| ||

Fig. 1.—Apparatus for Determination of Consistency. | ||

|