S.I. No. 109/1950 - Standard Specification (Woollen Blankets) Order, 1950.

S.I. No. 109 of 1950. | |||||||||||||||||||||||||

STANDARD SPECIFICATION (WOOLLEN BLANKETS) ORDER, 1950. | |||||||||||||||||||||||||

I, DANIEL MORRISSEY, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946), hereby order as follows : 1. This Order may be cited as the Standard Specification (Woollen Blankets) Order, 1950. 2.—(1) The specification set forth in Part II of the Schedule to this Order is hereby declared to be the standard specification for the commodity described in Part I of the said Schedule. | |||||||||||||||||||||||||

(2) The said standard specification may be cited as Irish Standard 26 : 1950. | |||||||||||||||||||||||||

|

SCHEDULE | |||||||||||||||||||||||||

PART I | |||||||||||||||||||||||||

WOOLLEN BLANKETS. | |||||||||||||||||||||||||

PART II | |||||||||||||||||||||||||

SPECIFICATION | |||||||||||||||||||||||||

SCOPE. | |||||||||||||||||||||||||

1. This specification covers the requirements for all-wool bed blankets. | |||||||||||||||||||||||||

TYPES. | |||||||||||||||||||||||||

2. Woollen blankets shall be of two types : first quality and second quality. | |||||||||||||||||||||||||

First quality woollen blankets shall be solid colour, or all-white, or white with coloured headings. First quality woollen blankets, which are all-white or white with coloured headings, shall be bleached. | |||||||||||||||||||||||||

Second quality woollen blankets shall be a grey mixture. | |||||||||||||||||||||||||

QUALITY AND COMPOSITION. | |||||||||||||||||||||||||

3. First quality woollen blankets shall be made exclusively from virgin wool, free from waste, shoddy or impurities. | |||||||||||||||||||||||||

Second quality woollen blankets shall be made exclusively from virgin wool and pure wool waste and shall contain not less than 662/3rd. per cent. of virgin wool. | |||||||||||||||||||||||||

Woollen blankets shall be clean scoured. | |||||||||||||||||||||||||

The loss in weight when treated with sulphuric acid according to the method described in Appendix A shall not exceed 1·5 per cent. for first quality woollen blankets and 2·5 per cent. for second quality woollen blankets. | |||||||||||||||||||||||||

CONSTRUCTION. | |||||||||||||||||||||||||

4. First quality woollen blankets shall be woven plain or 2/2 twill and shall contain not less than 21 warp threads per inch and not less than 20 weft threads per inch. | |||||||||||||||||||||||||

Second quality woollen blankets shall have a plain or a broken twill weave or a 2/2 twill weave and shall contain not less than 18 warp threads per inch and not less than 14 weft threads per inch. | |||||||||||||||||||||||||

The number of threads per inch shall be determined by the method described in Appendix B. | |||||||||||||||||||||||||

Woollen blankets shall be manufactured in conformity with the best manufacturing practice and shall be free from defects or blemishes that would affect their appearance or serviceability. | |||||||||||||||||||||||||

DESIGNATION. | |||||||||||||||||||||||||

5. Woollen blankets shall be designated as 3 lb., 3 ½ lb., 4 lb., 4 ½ lb., 5 lb. or 5 ½ lb. | |||||||||||||||||||||||||

DIMENSIONS AND WEIGHTS. | |||||||||||||||||||||||||

6. The dimensions of woollen blankets after binding or whipping shall be as set out in Table 1 for each designation. The dimensions shall be subject to a tolerance of minus 2 ½ per cent. in the width and minus 2 ½ per cent. in the length. The dimensions shall be determined by the method described in Appendix C. | |||||||||||||||||||||||||

Woollen blankets shall have a weight of 15 ounces per square yard with a tolerance of plus or minus 3 per cent. The weights of woollen blankets per square yard shall be determined as described in Appendix D. | |||||||||||||||||||||||||

TABLE 1. | |||||||||||||||||||||||||

| |||||||||||||||||||||||||

TENSILE STRENGTH. | |||||||||||||||||||||||||

7. The tensile strength of first quality woollen blankets shall be not less than 240 lb. in the warp direction and shall be not less than 180 lb. in the weft direction. | |||||||||||||||||||||||||

The tensile strength of second quality woollen blankets shall be not less than 230 lb. in the warp direction and shall be not less than 160 lb. in the weft direction. | |||||||||||||||||||||||||

The tensile strength of blankets shall be determined by the method described in Appendix E. | |||||||||||||||||||||||||

WHIPPING OR BINDING. | |||||||||||||||||||||||||

8. Woollen blankets shall have their ends securely whipped with 2/8s worsted yarn, or with its equivalent in rayon, so that the overlap shall be not less than 5/8th in. The whipping stitches shall be not more than ¼ in. apart measured on the side of the blanket on which the stitches are parallel to each other. | |||||||||||||||||||||||||

Alternatively, the ends of woollen blankets shall be securely bound with ribbon made of silk or rayon, of width not less than 2 ¾ in. The ribbon shall weigh not less than 1/3 ounce per linear yard for a width of 2 ¾ in. and correspondingly more for greater widths. | |||||||||||||||||||||||||

FASTNESS OF COLOURS TO WASHING. | |||||||||||||||||||||||||

9. Woollen blankets of solid colour or woollen blankets with coloured headings, and coloured whipping yarn or binding ribbon, when tested in the manner described in Appendix F, shall show no visible evidence of change in colour either through loss of depth or change in hue, and shall cause no staining of any white fabric with which they are in contact during the test. | |||||||||||||||||||||||||

MARKING. | |||||||||||||||||||||||||

10. Each woollen blanket conforming to this specification shall have the designation of the blanket and its dimensions as set out in Table 1, together with the manufacturer's name, initials or mark, clearly shown on a label stitched securely to one corner of the blanket. | |||||||||||||||||||||||||

CONDITIONING OF SAMPLES. | |||||||||||||||||||||||||

11. Samples used for determinations of the weight per square yard or tensile strength shall be conditioned by freely exposing them for at least 24 hours immediately before testing, in an atmosphere having a relative humidity of 65 to 70 per cent. and a temperature of 21°C. The determinations shall be made under the same conditions of relative humidity and temperature. | |||||||||||||||||||||||||

APPENDIX A. | |||||||||||||||||||||||||

DETERMINATION OF LOSS IN WEIGHT ON TREATMENT WITH SULPHURIC ACID. | |||||||||||||||||||||||||

A sample of blanket weighing about 2 g. shall be dried to constant weight in an oven at 105°C. to 110°C. and then weighed carefully to obtain the oven-dry weight, " W ". The sample shall be immersed for 7 to 10 minutes in 200 ml. of a boiling solution of 1 per cent. sulphuric acid. The sample shall be transferred to a Buchner or Hirsch funnel of 45 mm. diameter disc and the excess acid solution removed by suction. The sample shall be allowed to cool and then shall be held over a 400 ml. beaker and carefully cut into strips approximately 1/8th in. wide. 160 ml. of sulphuric acid of concentration 70 per cent (±1) by weight at 38°C. shall then be added. The exact concentration of the sulphuric acid solution shall be determined by titration. The liquid shall be stirred frequently, and after 15 minutes the mixture of the acid solution and fibres shall be poured cautiously but quickly into 600 ml. of cold water in a one-litre beaker. The 400 ml. beaker shall be rinsed with two 50 ml. portions of water and the washings added to the one-litre beaker. The fibres shall be filtered from the solution by suction, using a tared crucible with a sintered glass bottom. The fibres shall be rinsed with several portions of cold water, dried by suction, and then 200 ml. of a cold aqueous solution of sodium bicarbonate (2 per cent.) shall be added and the rate of filtering reduced so that the sodium bicarbonate solution comes in contact with the fibres for not less than 5 minutes. The fibres shall be rinsed again with several portions of cold water and dried by suction. | |||||||||||||||||||||||||

The fibres shall be dried at 105°C. to 110°C. to constant weight, " D ". | |||||||||||||||||||||||||

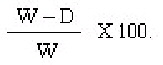

The loss in weight shall be taken as | |||||||||||||||||||||||||

APPENDIX B. | |||||||||||||||||||||||||

DETERMINATION OF THE NUMBER OF THREADS PER INCH. | |||||||||||||||||||||||||

(a) Number of warp threads per inch.—The number of warp threads per inch shall be determined at five different places across the blanket and the results averaged. The places shall be selected at distances not less than 6 in. apart and no determination shall be made nearer the selvedge than one-tenth the width of the blanket. The determinations shall be made over a width of blanket of not less than 3 inches. | |||||||||||||||||||||||||

(b) Number of weft threads per inch.—The number of weft threads per inch shall be determined at five different places along the blanket and the results averaged. These places shall be selected at distances of not less than 6 in. apart. The determinations shall be made over a length of blanket of not less than 3 inches. | |||||||||||||||||||||||||

APPENDIX C. | |||||||||||||||||||||||||

DETERMINATION OF DIMENSIONS. | |||||||||||||||||||||||||

The blanket shall be laid out without tension in either direction, on a smooth flat surface, care being taken to ensure that it is free from wrinkles or creases. | |||||||||||||||||||||||||

The distance between the outside edges of the headings in a line parallel to the selvedge shall be measured to the nearest ¼ in. The average of not less than 3 different measurements, uniformly distributed across the width, shall be taken to be the length of the blanket. | |||||||||||||||||||||||||

The distance between the selvedges in a line perpendicular to the selvedge shall be measured to the nearest ¼ in. The average of not less than 3 different measurements, uniformly distributed along the length, shall be taken to be the width of the blanket. | |||||||||||||||||||||||||

APPENDIX D. | |||||||||||||||||||||||||

DETERMINATION OF WEIGHT PER SQUARE YARD. | |||||||||||||||||||||||||

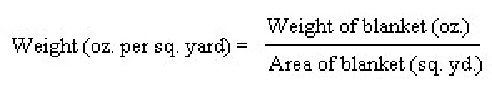

The blanket shall be conditioned as prescribed in Clause 11 and shall be weighed with an accuracy of not less than 0·1 per cent. The dimensions shall be determined as described in Appendix C. The weight per square yard shall be calculated to the nearest 0·1 oz. as follows : | |||||||||||||||||||||||||

APPENDIX E. | |||||||||||||||||||||||||

DETERMINATION OF TENSILE STRENGTH. | |||||||||||||||||||||||||

Samples at least 10 in. long and 7 in. wide shall be cut from the blanket, five in each direction warp and weft. No two samples in a warp or weft set shall include the same threads and the samples selected for the determination of weft strength shall be taken at different positions along the warp. No sample shall be taken nearer a selvedge than one-tenth the width of the blanket nor shall a sample be taken nearer a heading than one-tenth the length of the blanket. The samples shall be ravelled down to an exact width of 6 5/8 in. by removing approximately the same number of threads from each side, and shall be conditioned as prescribed in Clause 11. | |||||||||||||||||||||||||

The determinations shall be carried out on a horizontal testing machine with a rate of traverse of 18 in. per minute, the length of material between the grips being 7 in. and the full width of the sample being gripped by the clamps. | |||||||||||||||||||||||||

Determinations shall be made on each set of five samples and the average for each set of readings taken as the tensile strength. | |||||||||||||||||||||||||

Any determination made on a sample which breaks or slips in the clamps or breaks at the edge of a clamp, or any determination which for any reason attributable to faulty operation differs markedly from the average for the set, shall be regarded as faulty and shall be rejected. In such a case an additional sample shall be tested and the new result, if not faulty, shall be included in the calculation of the average result. | |||||||||||||||||||||||||

APPENDIX F. | |||||||||||||||||||||||||

DETERMINATION OF FASTNESS OF COLOURS TO WASHING. | |||||||||||||||||||||||||

On opposite sides of a 4 in. by 4 in. sample of blanket, which in the case of blankets with coloured headings includes a heading, shall be sewn 4 in. by 2 in. pieces of scoured unbleached white wool serge and also bleached white cotton limbric, by means of a single sewing along the common 4 in. edge. Whipping yarn or binding ribbon in sufficient quantity shall be cut in pieces 4 in. long and placed evenly between a piece of scoured unbleached white wool serge and a piece of bleached white cotton limbric, each measuring 4 in. by 4 in., and the composite sample completed by sewing around the edges of the white materials. | |||||||||||||||||||||||||

The composite sample shall be treated for 15 minutes in a solution containing 10 g. sodium acetate (CH3COONa.2H2O) per litre at a temperature of 50°C. the liquor to cloth ratio being 50 : 1. This treatment shall be repeated, using fresh sodium acetate solution, and the samples shall be well rinsed with distilled water after each treatment. The composite sample together with a solution of 2 g. soap flakes (moisture content 5 per cent. to 9 per cent.) per litre at 50°C. shall be placed in a jar of one pint capacity and shall be rotated for 45 minutes in a suitable apparatus so that the jar is turned completely end over end approximately 40 times per minute. The temperature inside the apparatus shall be maintained at 50°C. | |||||||||||||||||||||||||

After removal from the apparatus the composite sample shall be rinsed, and the fabrics separated and dried. The coloured sample shall be examined visually and compared with a piece of the original material. | |||||||||||||||||||||||||

GIVEN under my Official Seal this 24th day of April, 1950. | |||||||||||||||||||||||||

DANIEL MORRISSEY | |||||||||||||||||||||||||

Minister for Industry and Commerce. | |||||||||||||||||||||||||