S.I. No. 160/1949 - Standard Specification (Gold Size) Order, 1949.

S.I. No. 160 of 1949. | ||

STANDARD SPECIFICATION (GOLD SIZE) ORDER, 1949. | ||

I, DANIEL MORRISSEY, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946) hereby order as follows : 1. This Order may be cited as the Standard Specification (Gold Size) Order, 1949. 2.—(1) The specification set forth in Part II of the Schedule to this. Order is hereby declared to be the standard specification for the commodity described in Part I of the said Schedule. | ||

(2) The said standard specification may be cited as Irish Standard 17 : 1949. | ||

|

SCHEDULE. | ||

PART I. | ||

GOLD SIZE. | ||

PART II. | ||

SPECIFICATION. | ||

In this specification, the letters B.S., when followed by two sets of numbers, refer to the British Standard of which the first is the serial number and the second is the year of its publication by the British Standards Institution. | ||

SCOPE. | ||

1. This specification applies to gold size suitable for use as an adhesive for gold leaf and as a component of paints, varnishes and filling compositions. | ||

DESCRIPTION AND TYPES. | ||

2. The gold size shall be a clear and transparent oil varnish containing driers. It shall be one of two types, quick drying or slow drying, specified respectively as gold size type Q and gold size type S. | ||

DRYING TIME. | ||

3. Gold size type Q, when tested in the manner described in Appendix A, shall become surface dry in not more than 1 hour, and hard dry in not more than 4 hours. | ||

Gold size type S, when tested in the manner described in Appendix A, shall dry to a tack suitable for gilding in not less than 2 hours and shall retain that tack for not less than 9 hours. It shall become hard dry in not more than 24 hours. | ||

For the purpose of this clause the term " surface dry " shall mean a condition such that clean dry silver sand sprinkled on to the surface of the gold size film and kept there for one minute, can be removed by means of a camel-hair brush without injury to the gold size film. The sand used shall be graded so as to pass a No. 52 British Standard Test Sieve conforming to B.S. 410 : 1943, but to be retained on a No. 100 British Standard Test Sieve conforming to B.S. 410 : 1943. | ||

For the purpose of this clause the term " hard dry " shall mean a condition such that after slight rubbing down a second coat of gold size can be satisfactorily applied. | ||

VOLATILE CONTENT. | ||

4. The volatile content of the gold size, when determined in the manner described in Appendix B, shall not exceed 65 per cent. | ||

VISCOSITY. | ||

5. The viscosity of the gold size shall not be more than 5·5 poises at 15° C. or less than 1 poise at 25° C. For the purpose of this specification the method for the determination of viscosity given in B.S. 188 : 1937 shall apply. | ||

The term " poise " which is the unit of viscosity in the metric system is defined as the viscosity of a fluid in which one dyne is the tangential force on one square centimetre of either of two parallel planes separated by one centimetre, one of which moves in its own plane with a velocity relative to the other of one centimetre per second, turbulence being absent. The viscosity of distilled water at 20° C. is 0·01005 poise or approximately one centipoise. | ||

BEHAVIOUR WITH WHITE LEAD OIL PASTE. | ||

6. A mixture of the gold size and white lead oil paste prepared and stored as described in Appendix C shall not thicken to a stiff paste. | ||

KEEPING QUALITIES. | ||

7. Gold size shall be clear and free from deposit. It shall conform to the requirements of this specification after it has been kept in the dark in a closed container for seven days at a temperature of 15° C. to 20° C. | ||

SAMPLING AND SIZE OF SAMPLE. | ||

8. Representative samples, each measuring not less than one imperial pint, shall be taken in triplicate from one or more original and previously unopened containers, or from the bulk during filling. They shall be packed in clean dry air-tight non-absorbent containers made of material on which the sample has no action. Each container so filled shall be sealed and shall be marked with the date of sampling, and with sufficient information to identify the sample. | ||

APPENDIX A. | ||

Method for the Determination of Drying Time. | ||

A tin-plate strip 0·030 cm. in thickness (30 S.W.G.) and approximately .15cm. X 5 cm. shall be cleaned with cotton-wool moistened with benzene and weighed. One coat of the gold size shall be rapidly applied with a brush to one side of the strip and the strip shall then be re-weighed. By means of the brush the gold size shall be added to, or removed from, the film until the weight of the wet film as determined by rapid trial weighings is such as will produce when dry a uniform film weighing between 15·5 g. and 18·5 g. per square metre. | ||

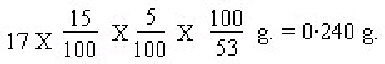

Example : If the sample of gold size contains 53 per cent. of volatile matter, the amount to be brushed on to one side of the strip to give a dry film weighing 17·0 g. per square metre would be : | ||

| ||

The film shall then be allowed to dry in a horizontal position in a well-ventilated room. During the drying period the film shall be exposed as long as possible to diffused daylight but not to direct sunlight. The temperature of the room shall be between 15° C. and 20° C. and shall be above the dew point. | ||

APPENDIX B. | ||

Method for the Determination of Volatile Content. | ||

One to 2 g. of the gold size shall be weighed into a flat-bottomed circular dish about 3 in. in diameter and 1 in. in internal depth. The dish and contents shall be heated for 3 hours in a suitable oven at 105° C. to 110° C. The dish shall then be allowed to cool to air temperature and be re-weighed. The percentage loss in weight shall be regarded as the volatile content. | ||

APPENDIX C. | ||

Method of Test for Behaviour with White Lead Oil Paste. | ||

A mixture of equal parts by weight of genuine white lead oil paste, conforming to B.S. 241 : 1935, and the gold size, shall be mixed with a palette knife on a glass slab, the operation being carried out as quickly as possible. The mixture shall then be transferred to a vessel of a size such that it is nearly filled with the mixture and the vessel shall be securely closed and kept for three days at a temperature of 15° C. to 20° C. | ||

GIVEN under my Official Seal this 23rd day of December, 1949. | ||

DANIEL MORRISSEY, | ||

Minister for Industry and Commerce. |