S.I. No. 91/1953 - Standard Specification (Heavy Duty Shovels) Order, 1953.

S.I. No. 91 of 1953. | ||

STANDARD SPECIFICATION (HEAVY DUTY SHOVELS) ORDER, 1953. | ||

I, SEÁN F. LEMASS, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946), hereby order as follows : 1. This Order may be cited as the Standard Specification (Heavy Duty Shovels) Order, 1953. 2.—(1) The specification set forth in Part II of the Schedule to this Order is hereby declared to be the standard specification for the commodity described in Part I of the said Schedule. | ||

(2) The said standard specification may be cited as Irish Standard 50 : 1953. | ||

|

SCHEDULE. | ||

PART I. | ||

HEAVY DUTY SHOVELS. | ||

PART II. | ||

SPECIFICATION. | ||

SCOPE | ||

1. This specification covers the requirements of long-handled steel shovels for road, quarry and other heavy duty purposes. | ||

SHAPE | ||

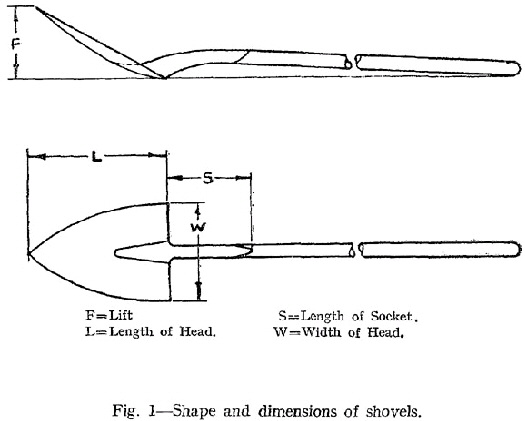

2. Shovels shall be of the general shape shown in Fig. 1. | ||

LIFT | ||

3. The lift, determined by measuring the height of the point of the blade above a level surface when the back of the head and the end of the handle are in contact with the level surface, shall be from 7 to 7½ inches. | ||

HEAD | ||

4. The head shall be of carbon steel and shall be free from seams or cracks. The blade and socket shall be one piece formed from a single piece of steel. The edge of the blade shall be tapered to form a cutting edge. The weight of the head including rivets shall not exceed 3 lb. 12 oz. | ||

The head shall be 9½ to 10 inches in width and 13 to 14 inches in length, the measurements being made as indicated in Fig. 1. | ||

The socket shall be shaped so as to encircle the handle completely and shall be not less than 8 inches in length when measured as indicated in Fig. 1. | ||

| ||

HANDLE | ||

5. The handle shall be of well-seasoned, straight-grained ash free from decay, wanes, knots, or splits. Sloping grain shall not diverge from the direction of the handle by more than 1 in 20. | ||

The handle shall be 4½ feet in length. It shall be not less than 1½ inches and not more than 15/8 inches in diameter. It shall be tapered at the socket end and approximately hemispherical at the other end. | ||

FITTING OF HANDLE | ||

6. The handle shall be tightly fitted in the socket and shall be fastened securely. | ||

FINISH | ||

7. The outer surface of the socket and the surface of the blade with the exception of the cutting edge shall be smooth. All exposed metal parts shall be completely painted, coated with lacquer, or treated to prevent rusting. Rivet heads and points shall be counter-sunk and smoothly finished. The handle shall be sanded to a smooth finish. | ||

HARDNESS | ||

8. The hardness of the shovel heads, when determined at any point not less than ½ inch, and not more than 2 inches from the cutting edge, shall be : | ||

a Rockwell hardness (C scale) of not less than 41 and not more than 46 under a load of 150 kilograms, or | ||

a Brinell hardness, measured with a 2 millimetre ball, of not less than 398 and not more than 444 under a load of 120 kilograms. | ||

DUCTILITY | ||

9. The shovel head shall have such a ductility that the lower 4 inches of the blade, when flattened by a steady pressure and then released, shall return to its former shape without visible permanent set or rupture of the metal. | ||

DEFLECTION | ||

10. The shovels, when tested by deflection as described in Appendix A, shall not show a greater permanent set than one inch. | ||

MARKING | ||

11. The shovels shall have the manufacturer's name or mark clearly stamped on the head. | ||

SAMPLES FOR TESTS | ||

12. For the purpose of testing conformity of shovels with this specification at least three shovels shall be selected at random from a lot of 100 shovels, but in lots of more than 100 two shovels per 100 or part thereof shall be selected at random. | ||

APPENDIX A | ||

DETERMINATION OF PERMANENT SET | ||

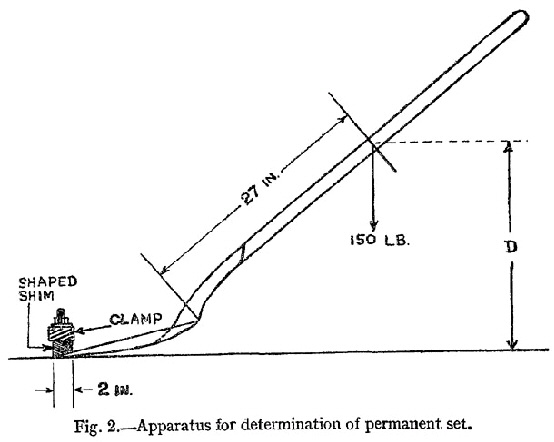

The blade of the shovel under test shall be clamped in a horizontal position using a suitably shaped wooden shim as shown in Fig. 2. The upper clamping surface shall extend across the width of the blade at right angles to the axis of the handle, and shall cover the tip of the blade up to a distance of 2 in. from the point. A load of 150 lb. shall be carefully applied at a point on the handle 27 in. from the shoulder of the blade. The load shall be applied for 2 minutes, and shall then be removed. The permanent set shall be measured at the point of application of the load as the difference before and after test in the vertical distance D. | ||

| ||

GIVEN under my Official Seal this 2nd day of March, 1953. | ||

SEÁN F. LEMASS, | ||

Minister for Industry and Commerce. |