S.I. No. 31/1953 - Standard Specification (Flush Wood Doors) Order, 1953.

S.I. No. 31 of 1953. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

STANDARD SPECIFICATION (FLUSH WOOD DOORS) ORDER, 1953. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

I, SEAN F. LEMASS, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946), hereby order as follows :— 1. This Order may be cited as the Standard Specification (Flush Wood Doors) Order, 1953. 2.—(1) The specification set forth in Part II of the Schedule to this Order is hereby declared to be the standard specification for the commodity described in Part I of the said Schedule. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The said standard specification may be cited as Irish Standard 48 : 1953. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SCHEDULE. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART I. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

FLUSH WOOD DOORS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART II. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

SPECIFICATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

In this specification, the letters I.S., when followed by two sets of numbers, refer to the Irish Standard of which the first is the serial number and the second the year of its promulgation by the Minister for Industry and Commerce. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

In this specification, the letters B.S., when followed by two sets of numbers, refer to the British Standard of which the first is the serial number and the second is the year of its publication by the British Standards Institution. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

SCOPE | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. This specification deals with flush wood doors suitable for normal housing requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

DESIGN | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

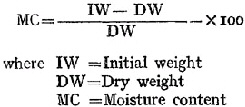

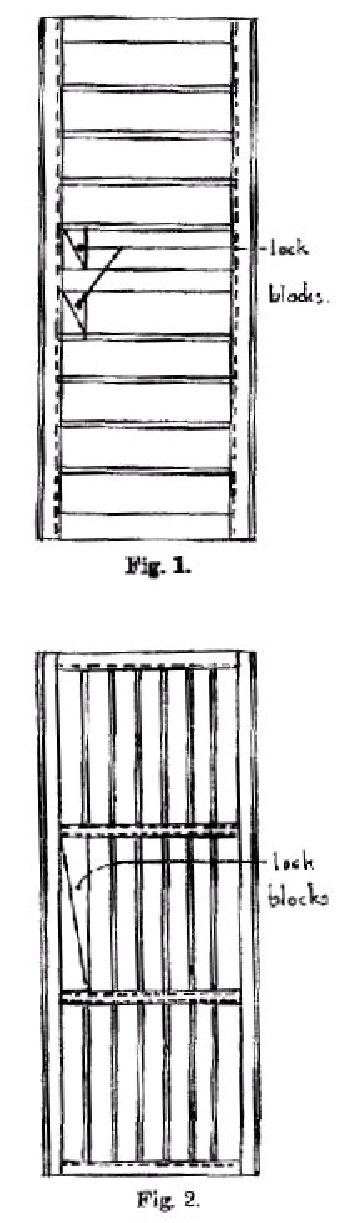

2. The doors shall consist of a wood core and plywood faces. The design shall be in accordance with either Fig. 1 or Fig. 2. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

DIMENSIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

3. The heights and widths of the doors shall be as set out in Table 1. The dimensions in Table 1 shall be subject to a tolerance of 1/8 in. The thickness of the finished door shall be not less than 17/8 in. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

DIMENSIONS OF CORE COMPONENTS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

4. The widths of the components of the core shall be not less than the values shown in Table 2. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE 2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

CONSTRUCTION OF CORE | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

5. Stiles, rails and infilling shall be stub-tenoned together. Stiles and rails may be built-up in their width from more than one piece of timber properly glue-jointed or lock-jointed. Horizontal rails shall be either grooved or bored to allow free circulation of air through all cavities. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

THICKNESS OF PLYWOOD FACINGS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

6. The thickness of plywood facings shall be 4 mm. for internal doors and 6 mm. for external doors. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

CORE TIMBER | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

7. The timber used for the core shall be of one of the following species: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

The moisture content of the core timber when determined by the method given in the Appendix A shall not be not less than 10 per cent. and not greater than 14 per cent. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

The slope of the grain in the components of the core, apart from local deviation due to knots, shall be not greater than 1 in 10. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

The core timber shall be free from all signs of decay and insect attack, from boxed heart and from case hardening and honeycombing. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

The core timber sahll be free from splits and shakes continuous between two surfaces. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

The core timber shall not contain knots or knot holes exceeding half the width of the cross section of the component. Where decayed or loose knots occur they shall be bored or cut out and tightly plugged with a cross-grained plug well glued in. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

Where pitch pockets and pitch streaks occur on the exposed edges of the door, they shall be cut out and filled in with fitted pieces of wood of similar species and character. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

PLYWOOD FACINGS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

8. The plywood used for facings shall be one of the following species: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plywood shall be of dry-cemented manufacture, using moisture-resistant adhesive in the case of plywood for internal doors and water insoluble adhesive for both faces of external doors. It shall be free from all signs of decay and insect attack. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

The face side of the plywood shall be flat, well sanded or scraped to form a smooth and level surface. The reverse side shall have no defect which reduces the adhesion of the plywood to the core. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

Where plywood has been scarf-jointed the inclination of the scarf to the grain of the outer ply shall be not steeper than 1 in 10. The presence of the joint shall not be perceptible to the touch and shall not be visible after painting. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPLICATION OF FACINGS TO CORE | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

9. Facing shall be applied to the core in a suitable press to ensure uniform adhesion and flat parallel surfaces. Metal fasteners shall not be used. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

The adhesives used in the construction of doors, shall conform to the requirements of B.S. 745: 1949 " Animal Glue for Wood," B.S. 1203 & 1204 : 1945 " Synthetic Resin Adhesives for Wood " or B.S. 1444 : 1948 " Cold Setting Casein Glue for Wood." External doors shall be assembled with an adhesive complying with Types B. 70 or B. 100 of B.S. 1204 : 1945. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

SLIPPING | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

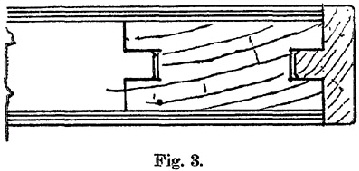

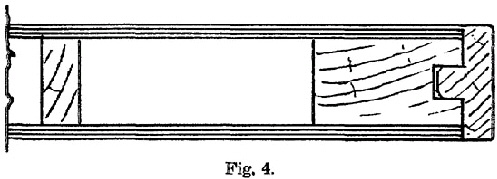

10. The stiles of the doors shall be edged with slips tongued to the stiles, out of 2 in. by 1 in. timber, properly glue-jointed in one piece to each stile, flush with plywood faces as shown in Fig. 3 and Fig. 4. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

OPENINGS FOR GLAZING | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

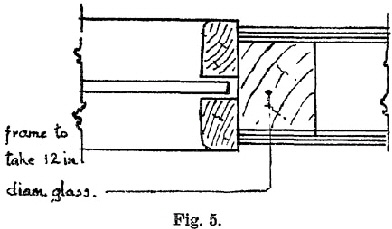

11. Where openings for glazing are to be provided they shall be circular or rectangular. Openings for glazing shall not exceed 13 in. diameter in the case of circular openings or 16 in. by 12 in. in the case of rectangular openings. The opening shall be framed in the core and shall be provided with glazing beads in four pieces, which shall be butt-jointed for circular openings and mitred for rectangular openings and loosely pinned within the thickness of the door as shown in Fig. 5. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

LOCK BLOCKS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

12. Lock blocks to take mortice or rim locks shall be fitted in the positions shown in Fig. 1 and Fig. 2. The position of the top and bottom of the block shall be clearly marked on the finished door thickness. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

WEATHER MOULDINGS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

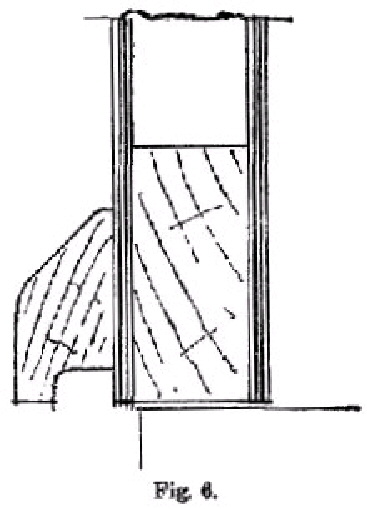

13. Weather mouldings, when required by the purchaser, shall be of the profile shown in Fig. 6. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

PROVISION FOR WATER BAR | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

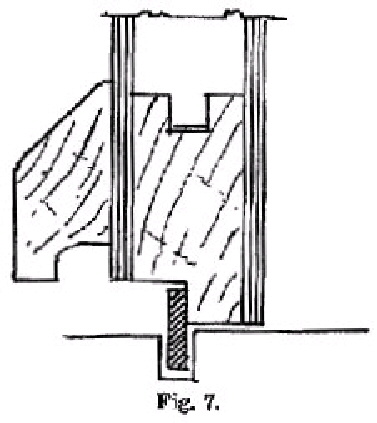

14. Where the door is required for use with a water bar, the bottom edge shall be rebated as shown in Fig. 7. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

PRIMING | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

15. All surfaces of doors, including loose beads and weather mouldings shall be knotted with knotting conforming to the requirements of I.S. 16 : 1949 and primed with a coat of priming oil paint conforming to the requirements of I.S. 18 : 1949. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

FINISH | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

16. The doors shall be flat, square and sanded to a smooth finish. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

MARKING | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

17. External doors shall be hammer-marked EXT. on the exposed stile head. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX A | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

METHOD FOR THE DETERMINATION OF MOISTURE CONTENT | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) Selection of Samples. For the purpose of carrying out the test for moisture content of the purchaser or his representative may select suitable samples of the timber. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

If the test for moisture content is to be carried out immediately after the cutting of the sample, these samples may take the form of the test pieces specified in (b) Method of Test; but if the first weighing cannot be carried out immediately after the cutting of the sample, the samples shall consist of pieces not less than 19 in. in length cut from the stock. The final test pieces shall be cut from the middle of the above pieces when the test is made. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) Method of Test. The test pieces of the timber shall be taken at a point not less than 9 in. from the end of the sample, and shall be cut to include the full cross section of the sample, and shall be in. long in the direction of the grain. They shall be weighed (IW) immediately after cutting and then dried in an oven at a temperature of 100°C. to 105°C.(212°F. to 221°F.) until the weight is constant (DW), and again weighed immediately after the removal from the drying oven. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

The percentage moisture content (MC) shall then be determined from the formula: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

GIVEN under my Official Seal this 19th day of January, 1953. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

(Signed) SEÁN F. LEMASS, | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

Minister for Industry and Commerce. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||