S.I. No. 156/1949 - Standard Specification (Cotton Bed Sheetings and Cotton Bed Sheets) Order, 1949.

S.I. No. 156 of 1949. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

STANDARD SPECIFICATION (COTTON BED SHEETINGS AND COTTON BED SHEETS) ORDER, 1949. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

I, DANIEL MORRISSEY, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946), hereby order as follows :— 1. This Order may be cited as the Standard Specification (Cotton Bed Sheetings and Cotton Bed Sheets) Order, 1949. 2.—(1) The specification set forth in Part II of the Schedule to this Order is hereby declared to be the standard specification for the commodity described in Part I of the said Schedule. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The said standard specification may be cited as Irish Standard 2 : 1949. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SCHEDULE. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART I. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

COTTON BED SHEETINGS AND COTTON BED SHEETS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PART II. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SPECIFICATION. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SCOPE. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. Section I of this specification covers the requirements of cotton sheetings suitable for the manufacture of bed sheets. Section II covers the requirements of cotton bed sheets. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SECTION I. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

COTTON SHEETINGS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

COMPOSITION. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2. The yarn in both warp and weft shall be composed entirely of thoroughly cleansed cotton free from waste. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MANUFACTURE. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3. Sheetings shall be of uniform width and weave and shall be manufactured in conformity with the best manufacturing practice. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TYPES AND GRADES. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4. Sheeting shall be one of the following types : | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plain bleached : first grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plain bleached : second grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twill bleached : first grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twill bleached : second grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twill bleached : third grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plain unbleached : first grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plain unbleached : second grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plain unbleached : third grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twill unbleached : first grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twill unbleached : second grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twill unbleached : third grade. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

WIDTHS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5. The widths of bleached sheetings shall be 54 in., 63 in., 70 in., 80 in., or 90 in., subject to a tolerance of plus 2 per cent. or minus 1 per cent. The widths of unbleached sheetings shall be 56 in., 65 in., 72 in., 83 in., or 94 in., subject to the same tolerance. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The width of sheetings shall be determined by the method described in Appendix A. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

THREADS PER INCH, WEIGHT, TENSILE STRENGTH AND FILLING. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6. The number of threads per inch, weight, tensile strength and amount of filling shall conform to the requirements set out for each type in Table 1. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Determinations of the number of threads per inch, the weight per square yard, the tensile strength and the percentage filling shall be carried out in accordance with the methods described in Appendices B, C, D, and E respectively. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Determinations of weight and tensile strength shall be made on materials conditioned in the open piece for not less than 24 hours in an atmosphere having a relative humidity of 65-70 per cent. and a temperature of 21° C. The tests shall be carried out under the same conditions of temperature and relative humidity. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SHRINKAGE. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7. When tested by the method described in Appendix F, the shrinkage of bleached sheeting shall be not more than 4 per cent. in the warp and 2 per cent in the weft, and the shrinkage of unbleached sheetings shall be not more than 6 per cent. in the warp and 2 per cent. in the weft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CUPRAMMONIUM FLUIDITY. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8. The apparent fluidity of a cuprammonium solution of the sheeting from which the sizing, finishing and other non-fibrous materials have been removed shall not exceed 7·5 reciprocal poises (rhes). The method of determining the apparent fluidity shall be the tentative method D 539-40 T : 1940 specified by the American Society for Testing Materials. The method used for preparing the sheeting for the test shall be that used for obtaining " clean dry fibre " as described in Appendix E. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MARKING OF SHEETING. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

9. Sheetings shall be clearly and indelibly marked at each end of each piece with the manufacturer's name or mark and the words " First grade ", " Second grade ", or " Third grade " to indicate the grade of the sheeting. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SAMPLES FOR TESTS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10. Samples of sheeting required for the tests described in the Appendices shall be cut and not torn from the piece at a position not less than three yards from the end of the piece. They shall be the full width of the sheeting and shall be not less than two yards in length. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SECTION II. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

COTTON SHEETS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MATERIALS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11. Cotton Sheets shall be manufactured from cotton sheetings conforming to the requirements of Section I of this specification. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FREEDOM FROM DEFECTS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12. Sheets shall be free from defects or blemishes affecting their appearance or serviceability. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

LENGTHS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

13. Sheets after hemming shall be 90 in., 100 in., 108 in., or 120 in., in length. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The lengths shall be determined by the method described in Appendix A. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

HEMMING. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14. Each sheet shall be free from seams, and shall be made from a single full width of material. It shall be hemmed at the ends but not at the sides. The finished hems shall be not less than 1 inch deep and shall have a turn-in of not less than ¼ inch. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The hems shall be securely and uniformly sewn with thread not finer than 50/3 cord, with a minimum of 10 stitches per inch. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

MARKING OF SHEETS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

15. Sheets shall be clearly, neatly and indelibly marked at one corner of a hem with the sheet manufacturer's name or mark, the dimensions, and a code mark to indicate the grade of the sheeting. The code mark shall be for First Grade sheeting " Gd A ", for Second Grade sheeting " Gd B " and for Third Grade sheeting " Gd C ". The height of the lettering used in the marking shall be 1/8 in. to 1/16 in. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SAMPLES FOR TESTS. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16. Samples for the purpose of testing for conformity with the specification shall be taken from a single sheet selected at random. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX A. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Determination of Width and Length. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Width of Sheeting and Sheets.—The material shall be laid out, without tension in either direction, on a smooth horizontal surface, so as to be smooth and free from wrinkles or creases. The distance between the outside edges on a line perpendicular to the selvedge shall be measured to the nearest 11/6 inch. Five measurements shall be taken in the case of sheeting and three measurements in the case of sheets, the measurements being made at different places so as to be representative of the width of the material and no measurements being taken within 12 inches from the ends. The average of the five measurements in the case of sheeting and of the three measurements in the case of sheets shall be taken as the width of sheeting or sheets. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Length of Sheets.—Sheets shall be laid out for measurement as described in the preceding paragraph. The distance between the outside edges of the hemmed ends of the sheet on a line parallel to the selvedge shall be measured to the nearest 1/16 inch. The three measurements shall be made at different places so as to be representative of the length of the sheet. The average of the three measurements shall be taken as the length of the sheet. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX B. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Determination of the Number of Threads per inch. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The number of warp threads per inch shall be determined by taking the average of five different measurements across the material. No measurements shall be made nearer the selvedge than one-tenth of the width of the material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The number of weft threads per inch shall be determined by taking the average of five different measurements along the material. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

All measurements shall be made over a distance of not less than 1 inch. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX C. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Determination of Weight. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

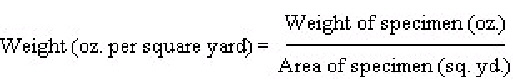

A specimen, of at least 100 square inches in area, having been fully conditioned, as set out in Clause 6, shall be measured to the nearest 1/16 in., and weighed with an accuracy of not less than 0·1 per cent. The weight per square yard shall be calculated to the nearest 0·1 ounce as follows: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX D. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Determination of Tensile Strength. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specimens at least 10 in. long and 4¼ in. wide shall be cut from the sample, five in each direction warp and weft. No two specimens in a warp or weft set shall include the same yarns and the specimens selected for the determination of weft strength shall be taken in different positions relative to the warp. No specimen shall be taken nearer a selvedge than one-tenth of the width of the sheeting. The specimen shall be ravelled down to an exact width of 4 in. by removing approximately the same number of yarns from each side, and conditioned as set out in Clause 6. The determinations shall be carried out on a horizontal testing machine with a rate of traverse of 18 in. per minute, the length of cloth between the grips being 7 in. and the full width of the specimen being gripped by the clamps. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Determinations shall be made on each set of five specimens and the average for each set taken. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Any determination made on a specimen which breaks or slips in the clamps or breaks at the edge of a clamp, or any determination which for any reason attributable to faulty operation differs markedly from the average for the set, shall be regarded as faulty and rejected and an additional sample shall be tested and the new result, if not faulty, shall be included in the calculation of the average result. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX E. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Determination of Percentage Filling. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

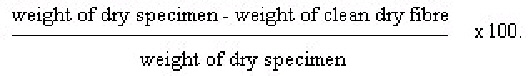

A specimen representative of the sample and weighing about 5 g., shall be dried in an oven to constant weight at 105° to 110° C. and this weight shall be termed " weight of dry specimen ". | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The dry specimen shall be extracted with carbon tetrachloride in a Soxhlet extractor for two hours at a rate such that the solvent is changed 10 times per hour during the operation. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The specimen shall be allowed to dry in air and then shall be immersed in distilled water and boiled gently for twenty minutes. It shall then be removed and the surplus water squeezed out. The specimen shall then be immersed in an aqueous solution at 50° to 60°C.containing a 3 to 5 per cent. solution of malt or other suitable enzyme. The specimen shall be squeezed while immersed then removed and squeezed again. This process of squeezing while immersed and after removal shall be repeated at least six times to ensure thorough wetting of the fibres by the enzyme solution. The specimen shall then be left immersed in the enzyme solution for one hour, the temperature of the solution during this time being maintained at the optimum temperature for the enzyme used. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The specimen shall be removed, squeezed, and then immersed for 30 minutes in boiling water and removed and squeezed and then rinsed three times in fresh portions of hot distilled water, squeezing after each rinse. Again the specimen shall be dried to constant weight at a temperature of 105° to 110° C. and this weight shall be termed " weight of clean dry fibre ". | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The percentage filling shall be taken as | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPENDIX F. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Determination of Shrinkage. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Creases present in the sample shall be removed by pressing with a heated flat iron. The fabric shall not be wetted and the iron shall not be caused to slide over the material. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

A test specimen taken from the sample shall be conditioned as set out in Clause 6. The specimen shall then be laid without tension in either direction, on a smooth flat surface, and shall be marked with three pairs of parallel marks in both warp and weft directions, the pairs of marks being staggered and evenly distributed across the test specimen. The minimum distance of any mark from the selvedge or edge of the test specimen shall be 2 in., and the distance between the pairs of marks on the test specimen shall be at least 18 in. The marking shall be carried out by inserting fast dye threads parallel to the warp or to the weft, or by the use of indelible ink. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The distance between the marks forming each pair shall be measured with a rigid rule having 1/16 in. graduations. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The test specimen shall be immersed in and saturated with water for a period of 2 hours, the water being maintained at a temperature of between 15° and 21° C. The test specimen shall be laid flat in the water throughout the period of immersion. On removal from the water the test specimen shall be squeezed by hand, without twisting, and shall then be allowed to dry on a flat surface. If drying is assisted by heat the temperature shall not exceed 50° C. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

When drying is complete the test specimen shall be damped by means of a fine spray of water in amount not more than sufficient to allow of the subsequent removal of creases. After damping, the test specimen shall be allowed to lie on a flat surface for five minutes. The test specimen shall be lightly pressed by means of a heated flat iron until it is free from creases. The iron shall not be allowed to slide over the fabric. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

After the test specimen has been conditioned as specified in Clause 6 it shall be re-measured between the marks on a smooth flat surface. Changes in dimensions in the warp and weft directions shall be separately recorded as percentages of the original values. The average of the three measurements in each direction shall be taken to the nearest 0.1 per cent. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GIVEN under my Official Seal this 23rd day of December, 1949. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DANIEL MORRISSEY, | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Minister for Industry and Commerce. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||